Are American Stainless Steel Hose Clamp suitable for extreme temperature and high pressure environments?

2025.07.18

2025.07.18

Industry News

Industry News

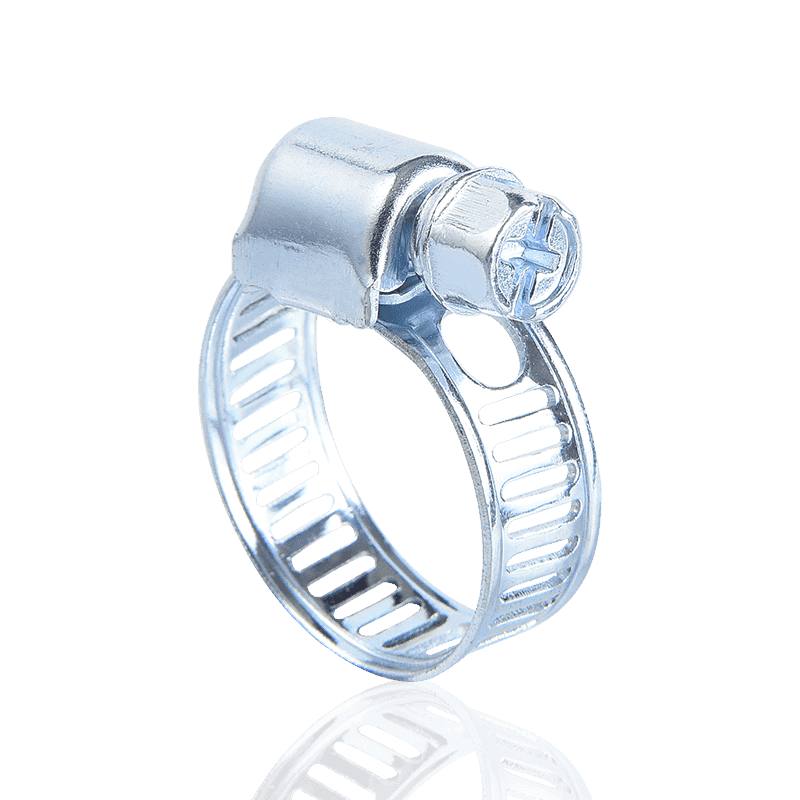

American Stainless Steel Hose Clamp are a type of fastener widely used in the fields of pipe connection, hose fixing, etc. Its design and material selection enable it to adapt to extreme temperature and high pressure environments to a certain extent. Specifically:

1. Applicability analysis

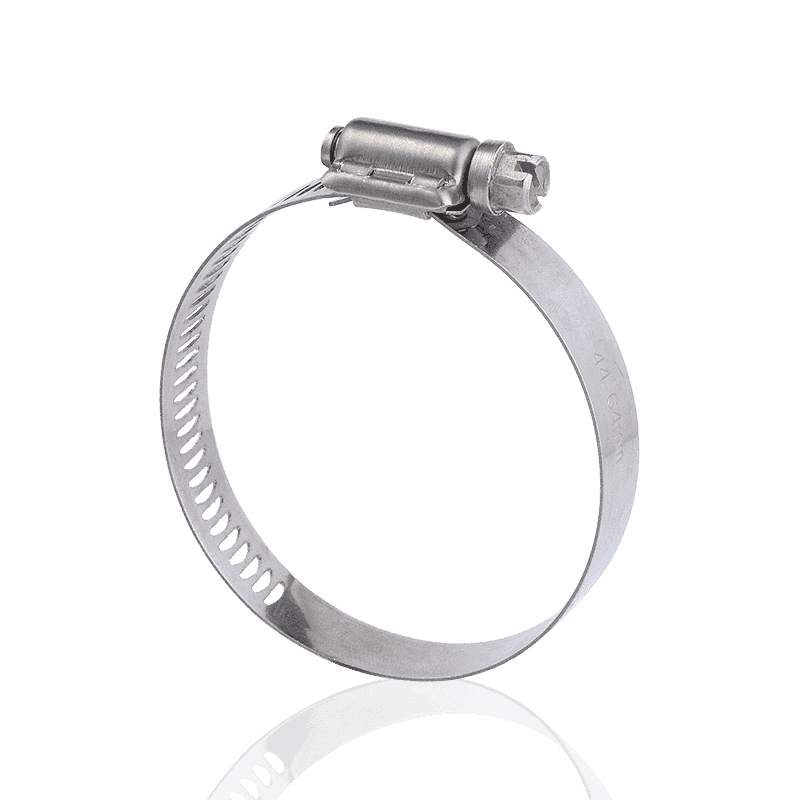

Material: American Stainless Steel Hose Clamp are usually made of 304 or 316 stainless steel, both of which have good corrosion resistance, high temperature resistance and mechanical strength. 304 stainless steel is suitable for general industrial environments, while 316 stainless steel is more suitable for environments containing chloride ions or other corrosive media.

Temperature resistance: The temperature resistance range of stainless steel throat hoops is usually between **-20°C and 200°C**, and some special models can withstand higher temperatures (such as above 300°C), so they are suitable for high-temperature equipment, chemical equipment, automotive engine systems, etc.

Pressure resistance: The design of American Stainless Steel Hose Clamp has good torsion resistance and torsional torque balance, can withstand large pressure, and is suitable for high-pressure pipeline systems, such as hydraulic systems, compressed air systems, etc.

Sealing: Due to its reasonable structural design, the screw and the steel belt are tightly engaged, which can effectively prevent medium leakage and is suitable for occasions with high sealing requirements.

2. Applicable scenarios

Extreme temperature environment: such as automobile engine intake system, high-temperature furnace, chemical reactor, etc.

High-pressure environment: such as hydraulic station, compressor outlet, high-pressure cooling system, etc.

Corrosive environment: such as acid and alkali transmission pipeline, marine equipment, food processing equipment, etc.

3. Precautions

Although American stainless steel throat clamps have good temperature and pressure resistance, the following points should still be noted during use:

Avoid overload: Do not exceed the rated pressure and temperature range of the throat clamp to avoid damage.

Regular inspection: During long-term operation, the tightness of the throat clamp should be checked regularly to prevent loosening due to vibration or fatigue.

Choose the appropriate model: Choose the appropriate throat clamp specifications and materials according to the actual working conditions to ensure safety and reliability.

What are the installation methods of American stainless steel throat clamps?

American stainless steel throat clamps have various installation methods, suitable for different scenarios and needs. The following is a detailed introduction to its main installation methods:

Standard installation method

This is the most common installation method and is suitable for most conventional hose or pipe connections. The user only needs to put the hose clamp on the connected hose or pipe, then pass the screw through the through hole and tighten it so that the steel belt and the screw are tightly engaged to achieve a firm connection. The torque value recommended by the manufacturer should be followed during installation to ensure the sealing and stability of the connection.

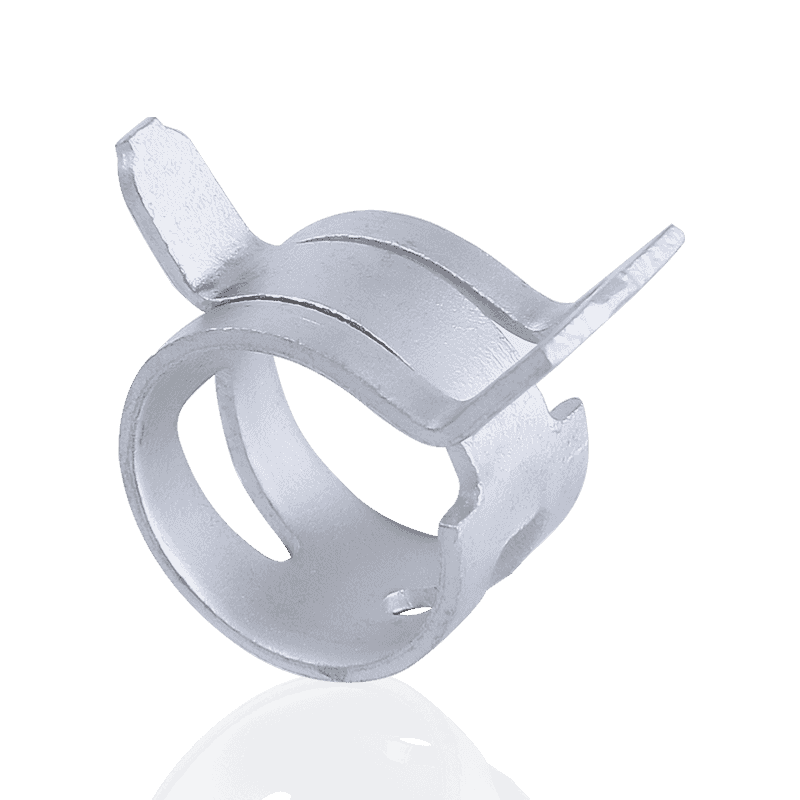

Quick release installation method

It is suitable for occasions that require frequent disassembly, such as when repairing or replacing hoses. This hose clamp is designed with a quick-closing buckle structure. The user only needs to press the buckle to achieve quick connection and fixation without additional tools. This method improves work efficiency and is particularly suitable for low-pressure or medium-pressure systems.

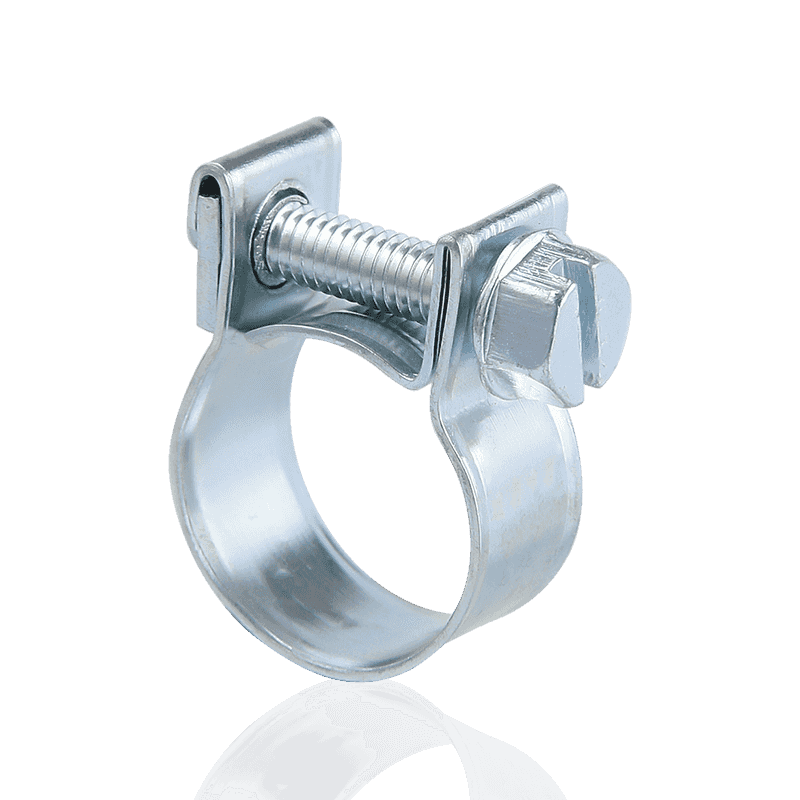

Specific application installation method

In some special application scenarios, such as the fixing of poles, large equipment or pipe bundles, the installation method of the hose clamp will be different. It is usually necessary to put the hose clamp on the bundled object and then lock it with a flat-blade screwdriver or hexagonal socket to ensure the firmness and overall stability of the connection. This method is suitable for the fixation of irregular shapes or large objects.

Handle installation method

Suitable for mid-to-high-end equipment or occasions with limited space. Some high-end models of hose clamps are equipped with a handle structure. Users can rotate or pull the handle to achieve a tight engagement between the screw and the steel belt, which is more labor-saving and especially suitable for single-person operation or environments where tools are difficult to use.

Adjustment and locking method

The installation of American stainless steel hose clamps also emphasizes the adjustment range and locking method. During the installation process, users can adjust the tightness of the hose clamp according to actual needs to ensure that it can adapt to hoses or pipes of different sizes and provide sufficient clamping force. When locking, ensure uniform force to avoid leakage problems caused by local deformation.