How to select British-type hose clamps?

2026.02.20

2026.02.20

Industry News

Industry News

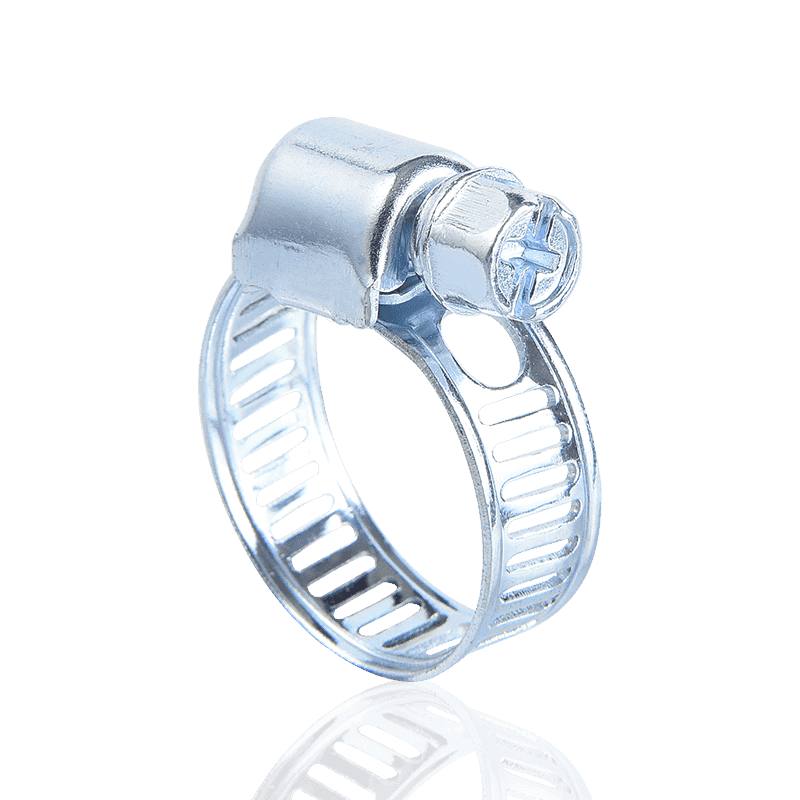

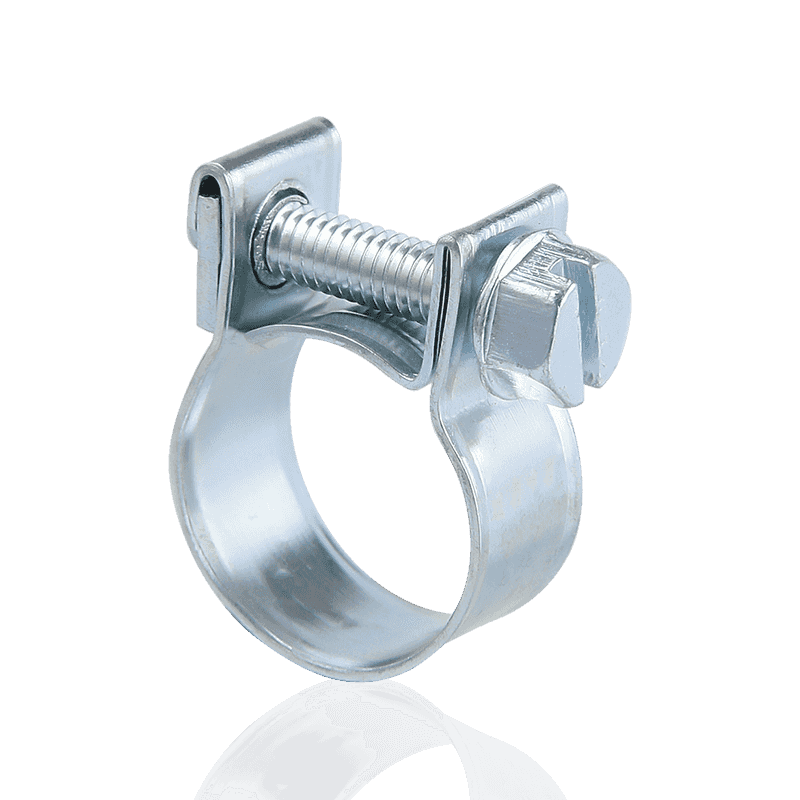

The core of selecting British-type hose clamps lies in matching pipe diameter size, working pressure, operating environment, and sealing requirements. Only when the specifications, materials, structure, and actual working conditions are properly matched can British-type hose clamps play their advantages of stable clamping, reliable sealing, and long-term durability, avoiding leakage, loosening, and frequent replacement problems.

- 1 Clarify pipe diameter size and hose outer diameter range

- 2 Different systems have different pressure level requirements

- 3 Material selection determines service life

- 4 Different environments have significantly different performance requirements

- 5 Structural design affects sealing stability

- 6 Industry application–matched selection direction

- 7 Quick selection reference table

Clarify pipe diameter size and hose outer diameter range

The first step in selecting British-type hose clamps is to confirm pipe diameter parameters: measure the hose outer diameter (OD), confirm the pipe diameter tolerance range, select a specification model with a matching adjustable range, and avoid problems of “too large to clamp tightly” and “too small to install.”

Recommended standard: clamping range ≥ hose outer diameter + 2–5 mm adjustment allowance, to ensure assembly and clamping stability.

Different systems have different pressure level requirements

| Application system | Recommended British-type hose clamp structure |

| Low-pressure water pipe systems | Standard structure |

| Medium-pressure pneumatic systems | Thickened steel band type |

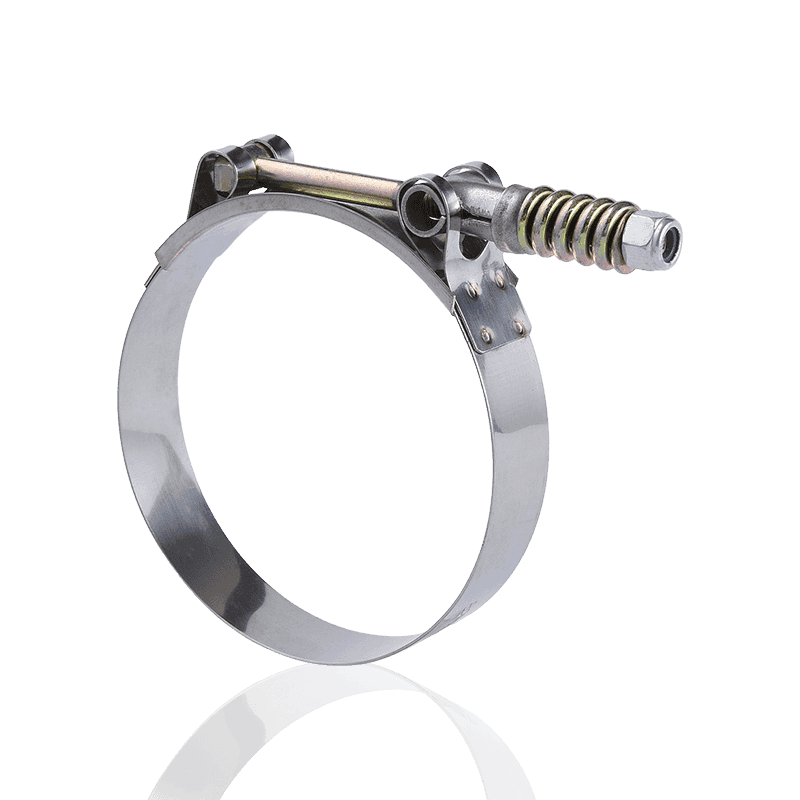

| High-pressure fluid systems | Reinforced screw structure |

| Industrial cooling systems | Wide-band high-strength type |

| Liquid delivery systems | Anti-slip tooth design type |

Conclusion: the higher the pressure, the wider the band, the thicker the steel strip, and the higher the screw strength requirements.

Material selection determines service life

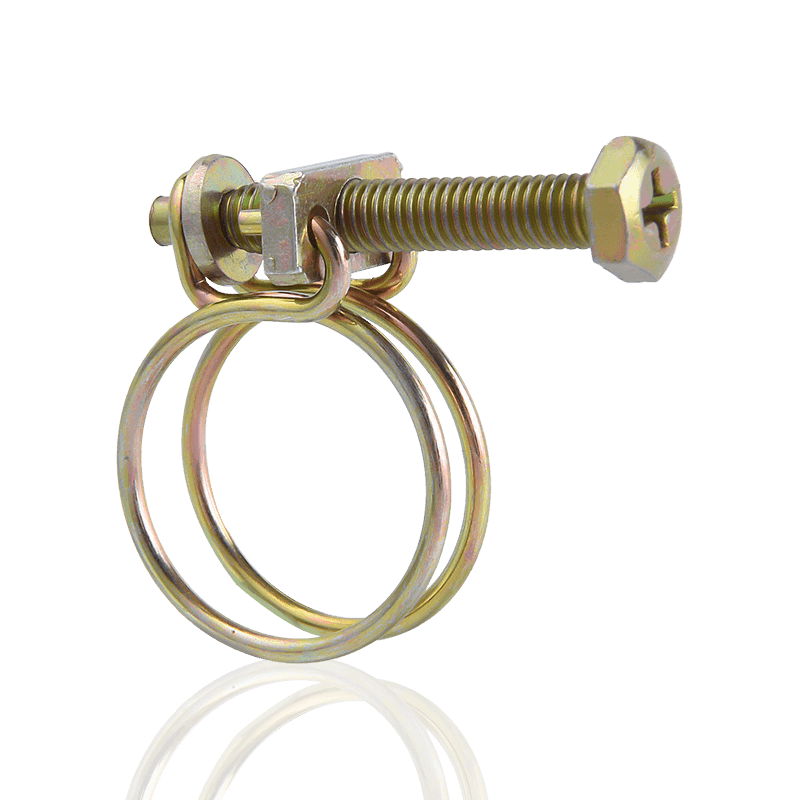

Common material types of British-type hose clamps:

- 201 stainless steel: economical type, suitable for general environments

- 304 stainless steel: strong corrosion resistance, suitable for humid and outdoor environments

- 316 stainless steel: salt spray corrosion resistance, suitable for marine environments and chemical environments

- Zinc-plated carbon steel: low cost, suitable for dry environments

Selection suggestions: Humid environments → 304 stainless steel; Highly corrosive environments → 316 stainless steel; Indoor conventional environments → 201 stainless steel or galvanized carbon steel.

Different environments have significantly different performance requirements

High-temperature environments: heat-resistant steel materials + high-strength screws

High-humidity environments: rust-resistant stainless steel materials

Strong vibration environments: anti-loosening structural design

Chemical corrosion environments: corrosion-resistant materials

Outdoor environments: rust prevention, anti-aging structures

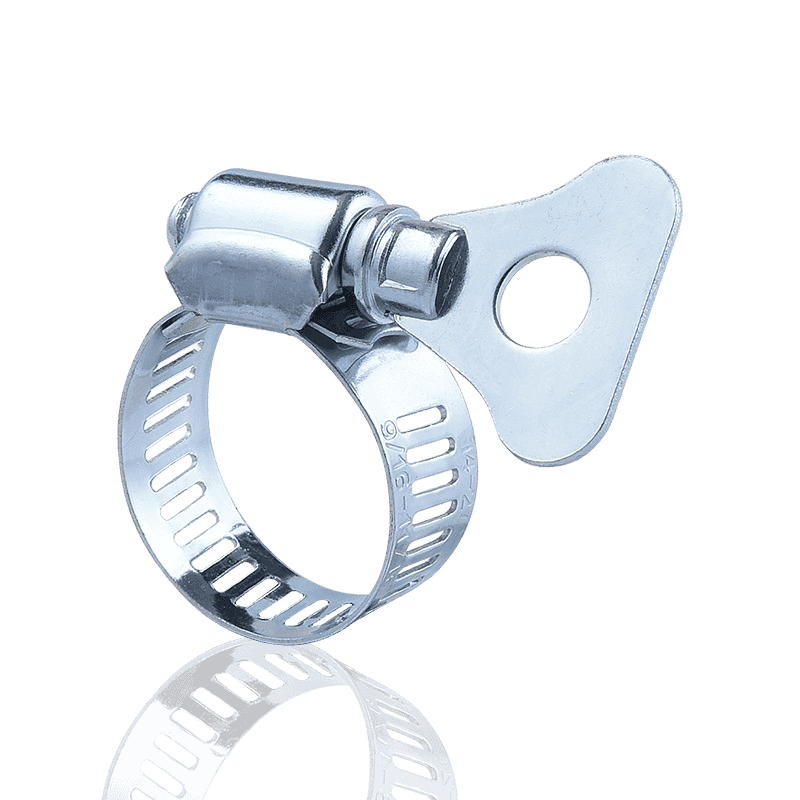

Structural design affects sealing stability

High-quality British-made hose clamps typically feature: uniform force clamping structures, precision threaded locking systems, anti-slip tooth steel band designs, wide-band surface contact clamping, and high-strength screw components. These structures can effectively reduce local stress concentration and improve sealing performance.

Industry application–matched selection direction

Typical application scenarios of British-type hose clamps include: industrial fluid delivery systems, cooling water pipe systems, automotive pipeline systems, air-conditioning and HVAC systems, food equipment pipelines, medical equipment pipelines, agricultural irrigation systems, and household pipeline connections. Different scenarios correspond to different selection standards.

Common selection mistakes: Only looking at price but not material, only choosing specifications but not pressure rating, ignoring environmental corrosiveness, too narrow band width causing uneven clamping, insufficient screw strength causing thread slipping, ignoring long-term stability.

Quick selection reference table

| Selection factor | Recommended standard |

| Pipe diameter matching | Outer diameter + 2–5 mm adjustment space |

| Material | 304/316 stainless steel preferred |

| Band width | Wide-band type for medium–high pressure systems |

| Screw | High-strength anti-slip thread |

| Environment | Corresponding corrosion resistance grade |

| Application | Match according to industry working conditions |

British-type hose clamp selection is not a casual choice, but a system-matching engineering task. Reasonable selection can significantly improve pipeline system safety, sealing stability, and service life, reduce maintenance costs and failure risks. As industrial equipment and system stability requirements continue to increase, British-type hose clamps are gradually upgrading from ordinary accessories to key safety connecting components, becoming important components of high-quality pipeline systems.