What are the main functions of Heavy Duty Hose Clamp?

2025.08.15

2025.08.15

Industry News

Industry News

1. Secure the hose and fitting

The main function of a heavy-duty hose clamp is to secure the hose to the fitting or pipe, preventing it from slipping, falling off, or leaking due to vibration, pressure, or movement during use.

2. Ensure a tight seal

By providing sufficient clamping force, Heavy Duty Hose Clamp ensure a tight seal between the hose and fitting, preventing leakage of fluids (such as liquids, gases, and oils).

3. Improve connection reliability

In industrial, medical, and laboratory environments, the reliability of hose connections is crucial. Heavy Duty Hose Clamp provide stable clamping force, ensuring a stable and secure connection.

4. Adapt to various working conditions

Heavy Duty Hose Clamp are typically corrosion-resistant, high-temperature-resistant, and high-strength, making them suitable for a variety of complex working conditions, such as high pressure, high temperature, and corrosive environments.

5. Easy installation and adjustment

Heavy Duty Hose Clamp are often designed to adjust to the size of the hose to ensure optimal clamping. Some models also feature quick installation and removal for easy maintenance and replacement.

6. Extended Service Life

With proper installation and maintenance, Heavy Duty Hose Clamp can extend the service life of hoses and fittings, reducing failures and repair costs caused by poor connections.

7. Improved Safety

In critical applications such as industry, healthcare, and laboratories, the reliability of hose connections is directly related to operational safety. Heavy Duty Hose Clamp contribute to overall system safety by providing a reliable connection.

Which Hose Clamp is Best?

Hose clamps are primarily categorized into different types, including American, German, British, T-type, spring-loaded, and wire-type, each with its own specific applications and characteristics.

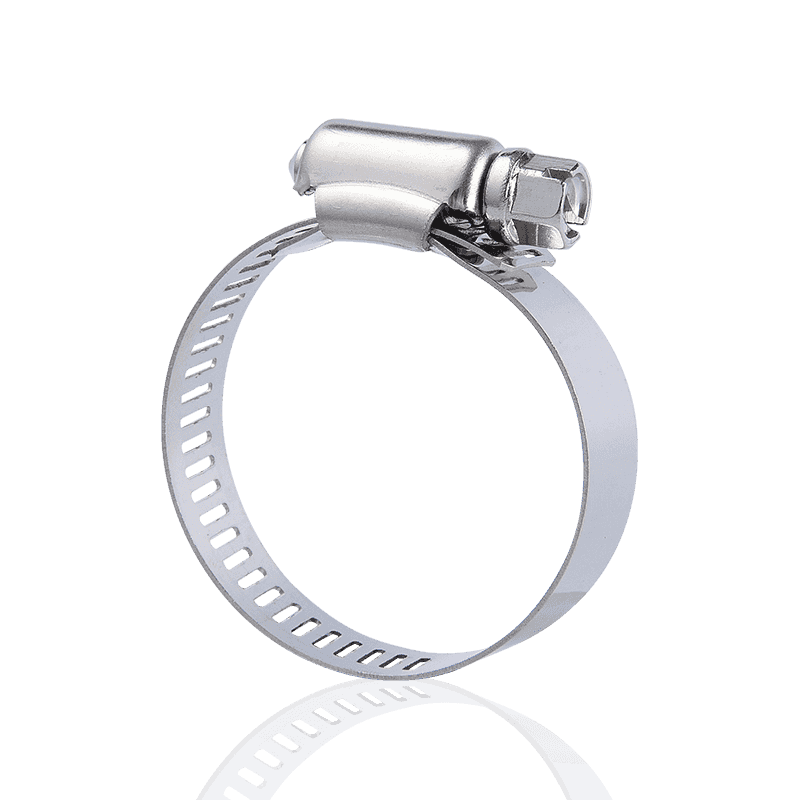

American Hose Clamps: Utilizing a through-hole process, they are suitable for mid- to high-end vehicle models and connections involving corrosion-resistant materials, offering excellent torsion and pressure resistance.

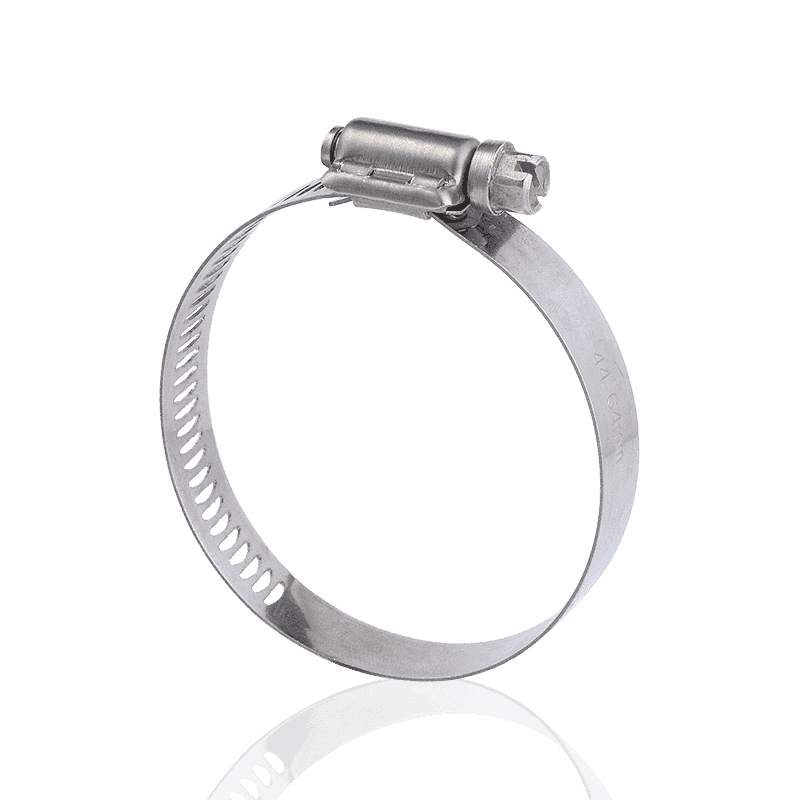

German Hose Clamps: They offer high torque resistance and uniform force distribution, making them suitable for high pressure and complex environments, and are commonly used in the industrial and automotive sectors.

British Hose Clamps: They are lower cost and suitable for general industrial and agricultural applications, but they offer relatively low tightening force.

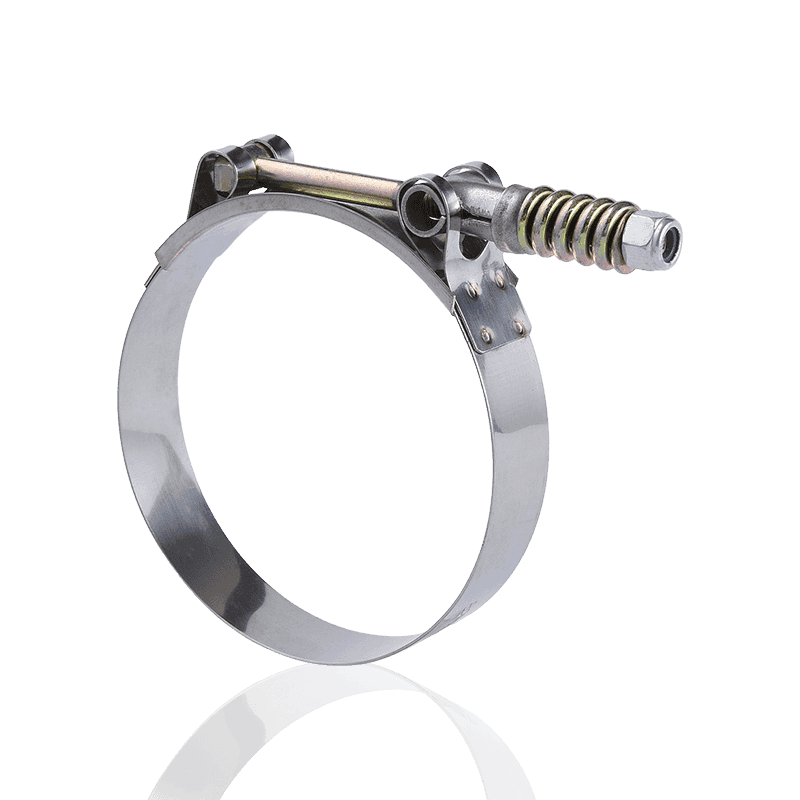

T-Type Hose Clamps: Compact, suitable for large-diameter pipes and high-pressure environments, and offer excellent sealing performance.

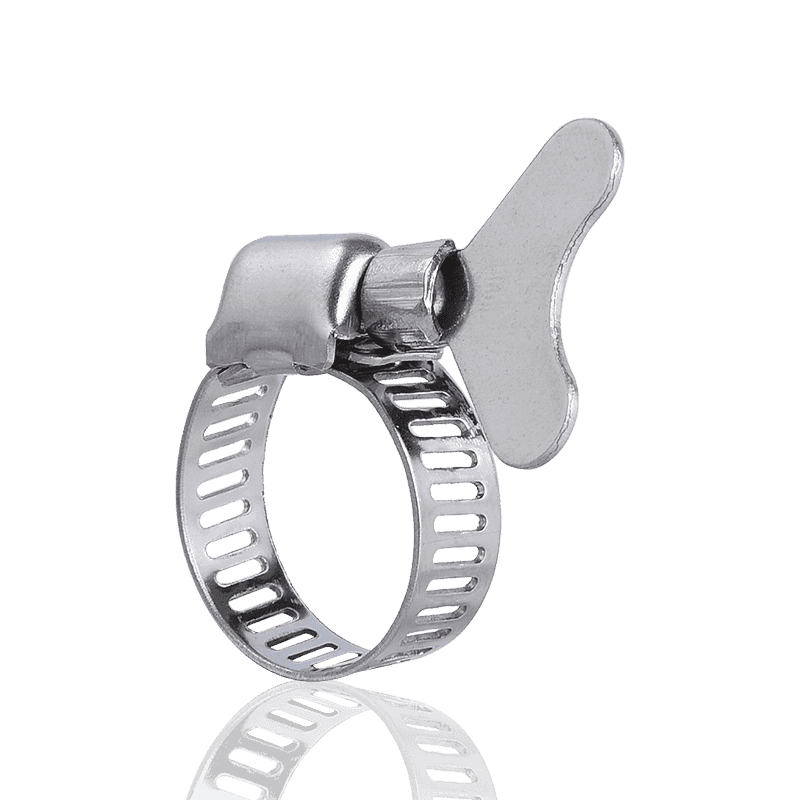

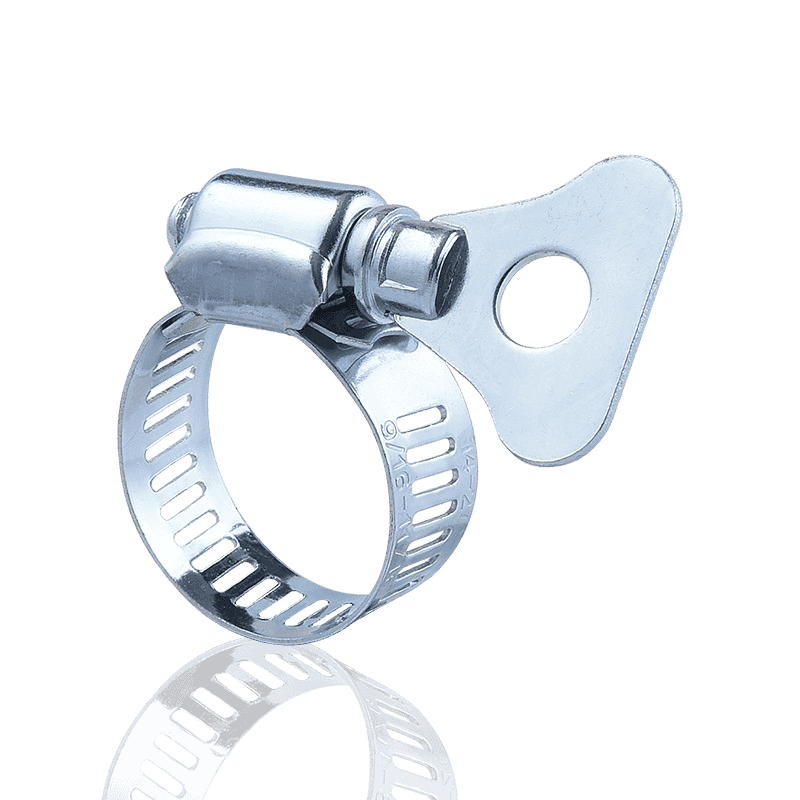

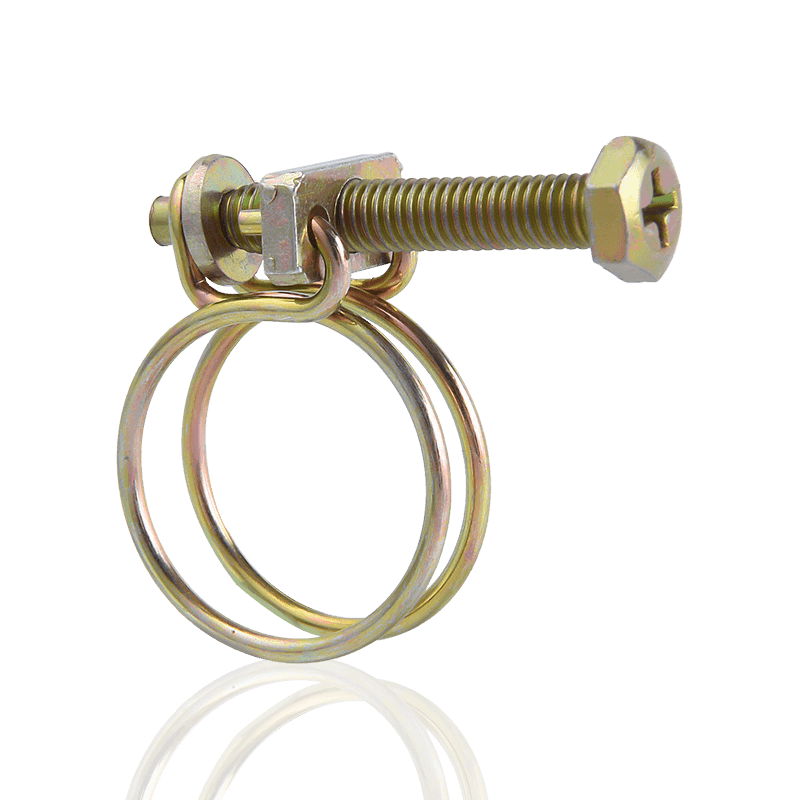

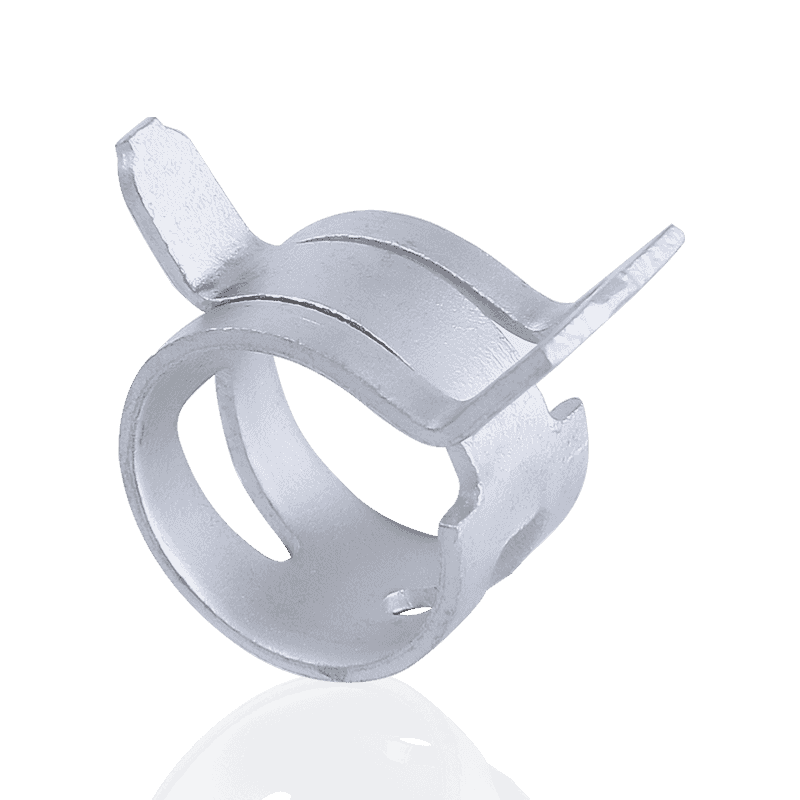

Spring-loaded hose clamps: Suitable for applications involving frequent assembly and disassembly, such as water pipe connections.

When selecting a hose clamp, consider the following factors:

Use Environment: For applications involving high temperatures, high pressures, or corrosive environments, you may need to choose a hose clamp that is heat-resistant and corrosion-resistant.

Tightening Force Requirement: Different types of hose clamps have different tightening forces, so the selection should be based on actual needs.

Ease of Installation and Maintenance: For applications involving frequent assembly and disassembly, you may need a hose clamp that is easy to install and remove.

Cost-Performance Balance: Different types of hose clamps vary in performance and price, so a balance should be considered based on budget and needs.

There is no single standard for the "best" hose clamp; choosing the most appropriate one depends on the specific application and requirements. For example:

Industrial and high-pressure environments: German-style hose clamps or T-type hose clamps may be more suitable.

Automotive and mid-to-high-end applications: American-style hose clamps or German-style hose clamps may be more suitable.

For applications involving frequent assembly and disassembly: Spring-loaded hose clamps or hose clamps with plastic handles may be more convenient.