Which hose clamp is best?

2025.10.03

2025.10.03

Industry News

Industry News

Hose clamps are crucial fasteners for connecting and securing hoses in numerous applications, including industrial, automotive, plumbing, and household applications. Faced with the myriad hose clamp types on the market, many people wonder: Which hose clamp is best? The answer isn't absolute, as the "best" depends on your specific application needs.

Common Hose Clamp Types and Their Characteristics

Mainstream hose clamps on the market can be categorized into several main types based on their design and locking mechanism:

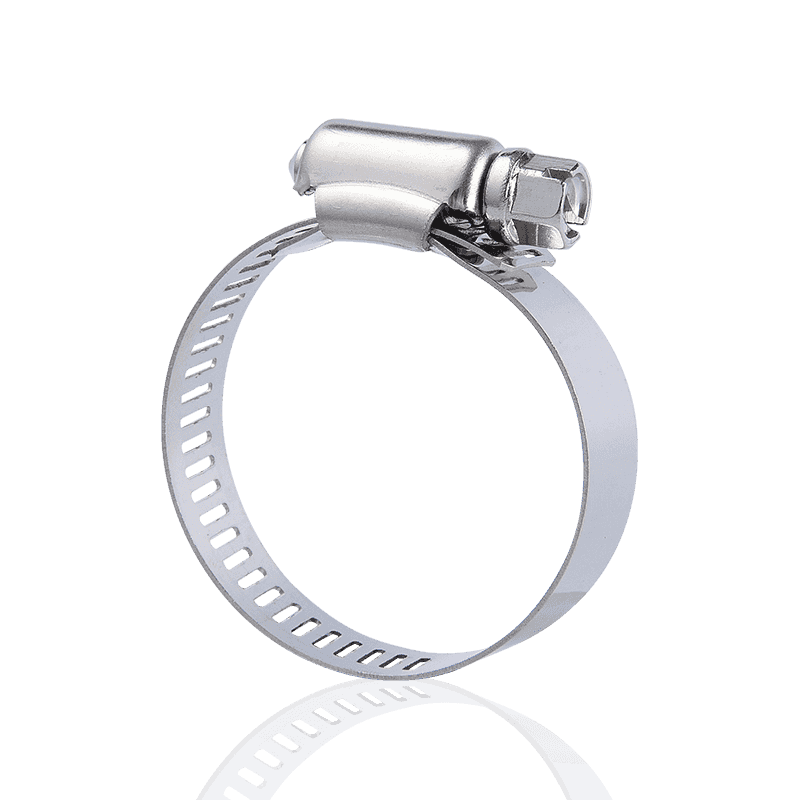

1. Threaded-Drive Hose Clamp (Worm Gear)

This type of hose clamp is the most widely used. The worm gear mechanism tightens or loosens the steel band by rotating a screw.

American-Style Hose Clamp (Through-Hole):

- Features: The steel band has punched holes through which the screw teeth engage. Based on the information you provided, American-Style Hose Clamps utilize a through-hole process, offering advantages such as torsion and pressure resistance, balanced torque, secure locking, and a wide adjustment range. They also offer greater tensile strength than German-Style Hose Clamps and a more aesthetically pleasing appearance after assembly.

- Applications: Widely used for hose connections in automotive piping, water pumps, fans, food processing, chemical machinery, and other industries.

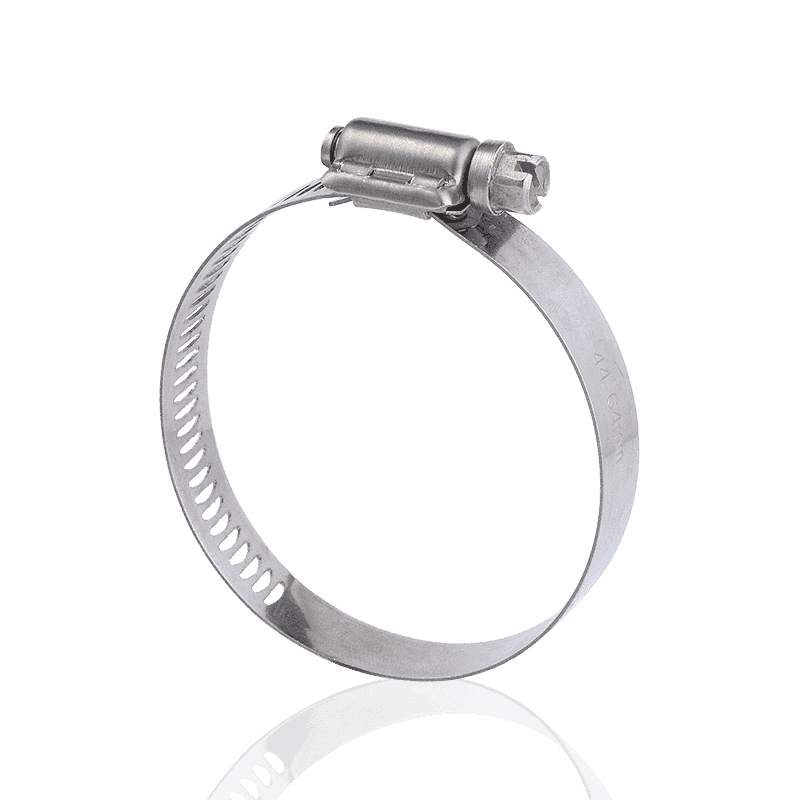

German-Style Hose Clamps:

- Features: The steel band typically features wavy embossing rather than through holes, ensuring more uniform pressure and a better seal.

- Applications: Suitable for environments with high sealing requirements and high vibration.

2. Spring-Loaded Hose Clamps (Clamps)

This type of hose clamp utilizes the elasticity of spring steel to clamp the hose.

- Features: Easy and quick installation. Its greatest advantage is that it automatically compensates for thermal expansion and contraction of the hose and fitting during temperature fluctuations, maintaining a constant clamping force.

- Applications: Automotive and mechanical applications with frequent temperature fluctuations, such as engine cooling systems and heating systems.

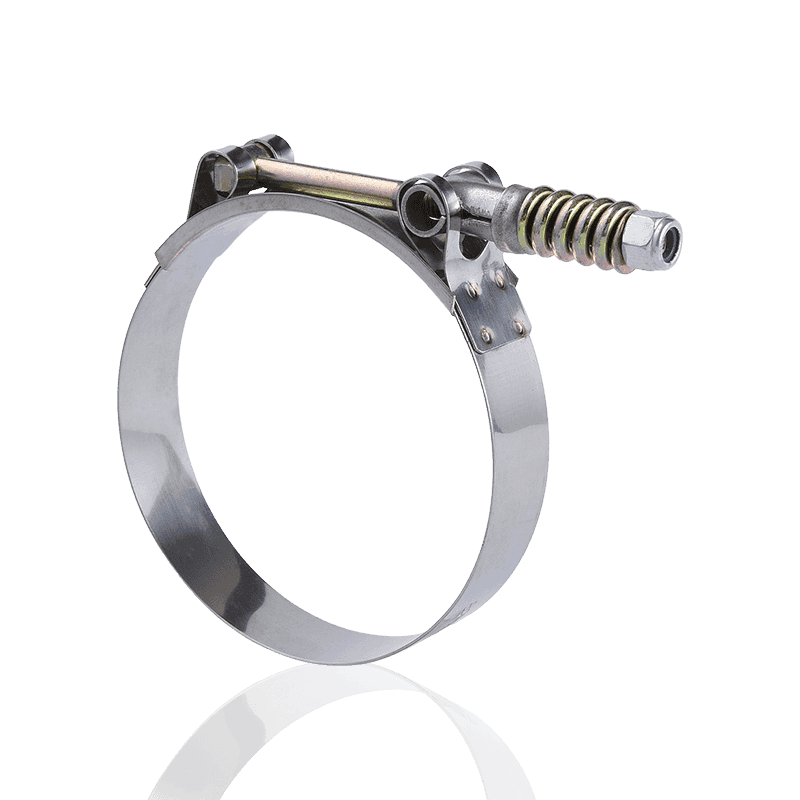

3. T-bolt Hose Clamps

T-bolt hose clamps are typically used in applications subject to high pressure and heavy loads.

- Features: Using a single T-bolt and nut for fastening, they provide extremely high clamping force and strength, ensuring high reliability.

- Applications: Connecting high-pressure or large-diameter hoses in turbochargers, heavy machinery, industrial piping, and other applications.

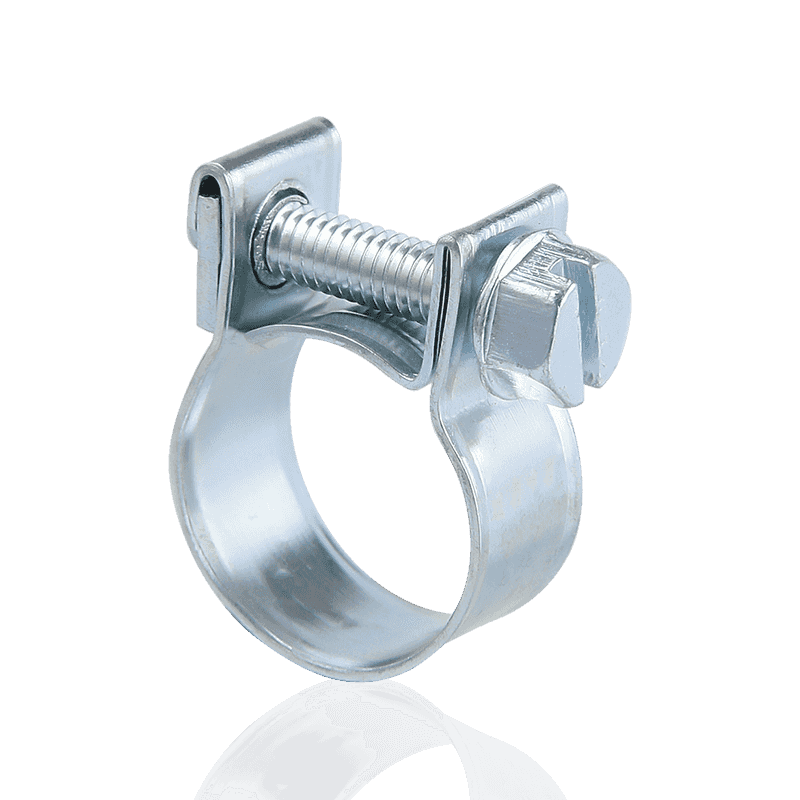

4. Single-Ear/Double-Ear Stepless Hose Clamp

This type of hose clamp (commonly known as an O-ring or crimp ring) is tightened in one go using a specialized tool.

- Features: No gaps, a 360-degree, uniform seal, tamper-resistant, and compact design.

- Applications: Fuel lines, hydraulic systems, and automotive repairs requiring a high degree of sealing.

How to Choose the "Best" Hose Clamp?

To choose the "best" hose clamp, consider the following key factors:

| Factors | Influencing Results | Recommended hose clamp types: |

| Working pressure | Higher pressures require greater clamping force. | T-bolt clamps, heavy-duty thread-driven clamps. |

| Temperature fluctuations | Severe changes in pressure can cause the hose to contract or expand. | Spring-loaded clamps (automatic compensation). |

| Sealing requirements | Is absolute leak prevention necessary? | Single-ear/double-ear stepless clamps (provide a 360° seal). |

| Hose material | Hose stiffness and elasticity. | American/German-style hose clamps (widely applicable). |

| Corrosion resistance | Is the environment exposed to water, chemicals, or salt spray? | Stainless steel hose clamps (e.g., 304, 316). |

| Ease of installation | Does the hose need to be frequently disassembled and reused? | Thread-driven hose clamps. |

Material Considerations - The Key to Durability

The material of a hose clamp directly determines its lifespan and applicable environment. Common materials include:

- Stainless steel: Provides excellent corrosion resistance and strength, suitable for humid, outdoor environments, or chemical machinery. For example, the American-style hose clamp you mentioned is available in both stainless steel and carbon steel.

- Galvanized/carbon steel: Lower cost and suitable for dry, less corrosive environments. However, it can easily rust in humid environments with long-term use.

There's no such thing as a "best for all" hose clamp. For most everyday and general-purpose needs, such as water system connections, American hose clamps offer a highly cost-effective choice due to their secure locking and wide adjustment range. However, for high-pressure industrial applications, T-bolt clamps should be chosen. For automotive engine cooling systems, spring clamps with self-compensating capabilities offer advantages.