Why can the American Type Plastic Handle Hose Clamp be used to effectively prevent pipeline leakage?

2025.03.07

2025.03.07

Industry News

Industry News

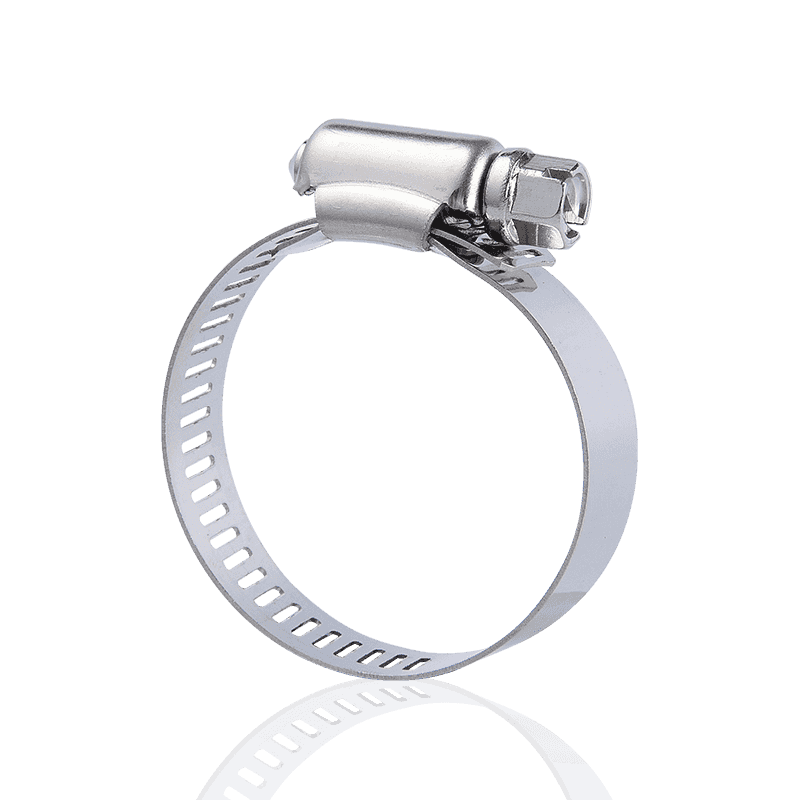

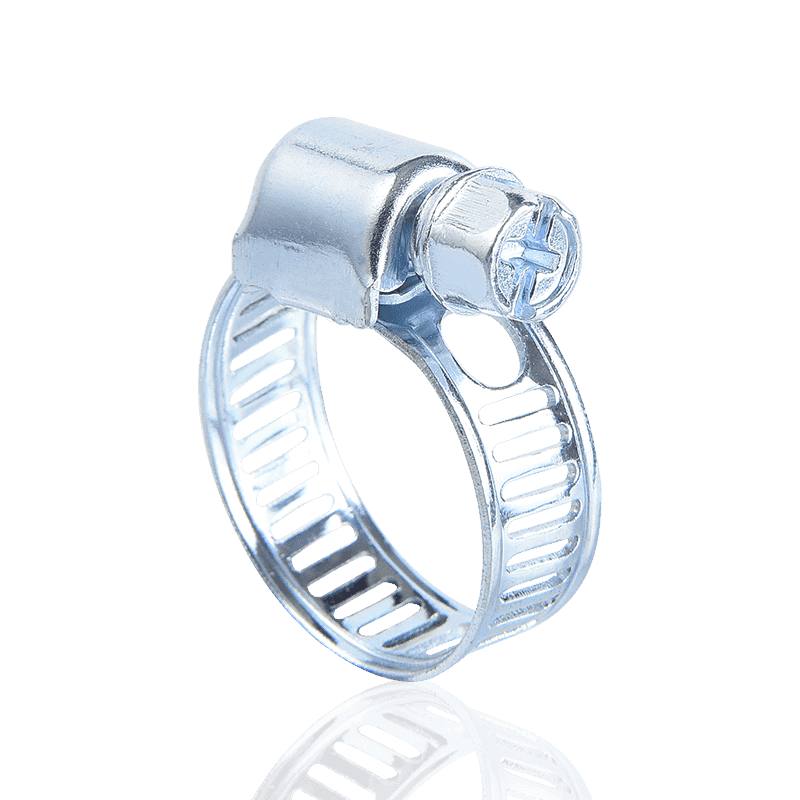

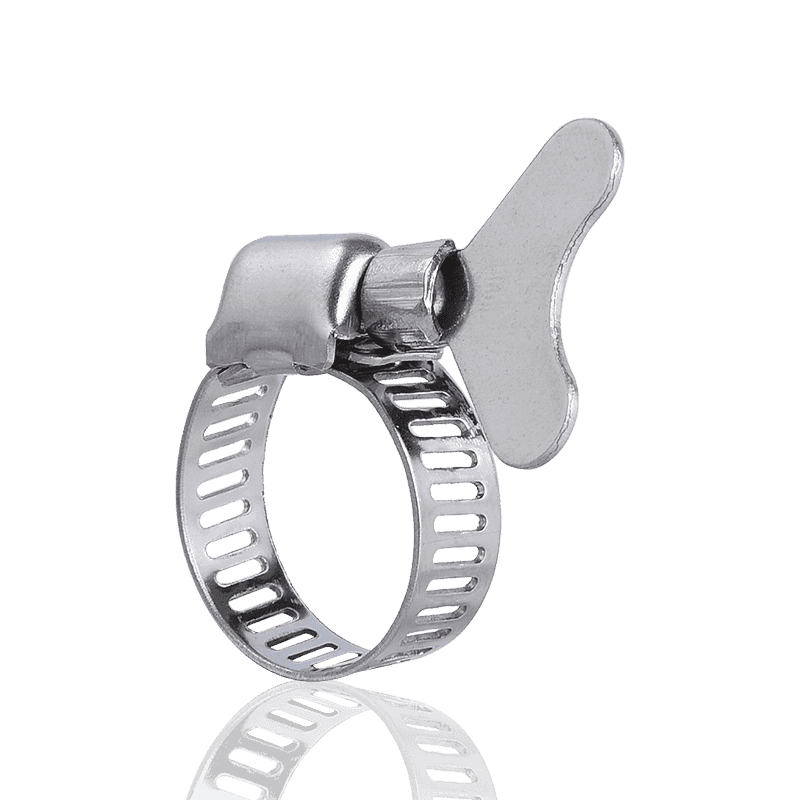

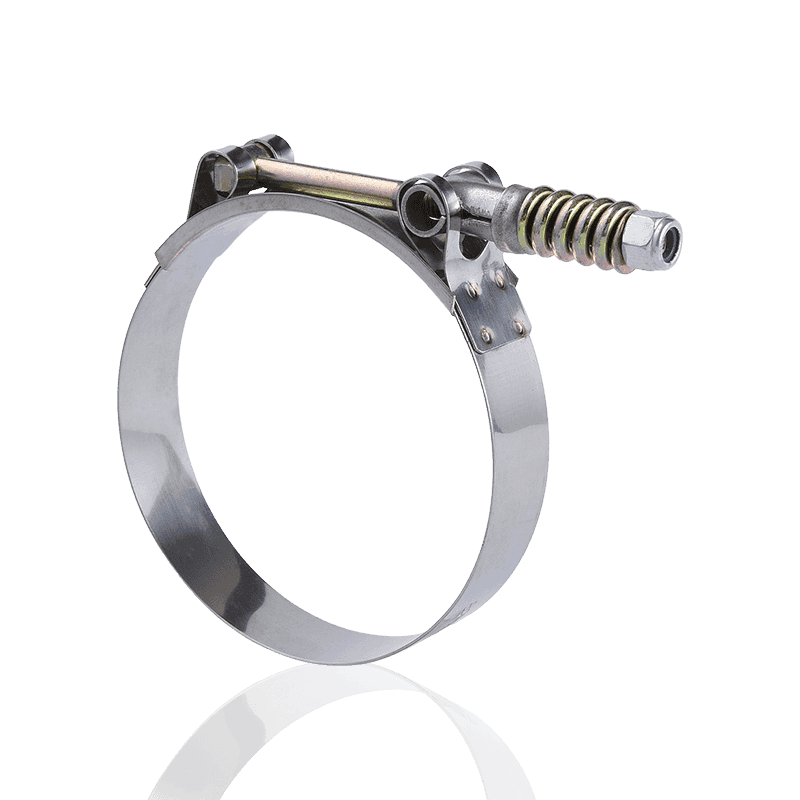

The American Type Plastic Handle Hose Clamp is made of high-quality plastic. This material not only provides a good feel and makes operation easier, but also has certain wear resistance and corrosion resistance, and can maintain stable performance in various environments. The design of the plastic handle also takes ergonomics into consideration, ensuring that users can hold it comfortably and reduce fatigue during use. Made of high-strength steel, this steel has excellent tensile strength and yield strength, and can withstand large pressure and tension, ensuring that the throat clamp will not be deformed or damaged during the tightening process. The surface of the steel belt is usually specially treated to improve its corrosion resistance and service life.

The design of the American Type Plastic Handle Hose Clamp takes into account many factors to ensure that it can effectively prevent pipeline leakage. The steel belt is designed with rectangular holes and grooves. This design not only reduces the weight of the throat clamp, but also provides a strong and precise bite force. When the throat clamp is tightened, the steel belt can firmly lock the pipe to form a tight seal. The rectangular hole and groove design also makes it easier for the hose clamp to adapt to pipes of different diameters during the tightening process, improving its versatility and flexibility.

The combination of the plastic handle and the steel band not only improves the operability of the hose clamp, but also allows the hose clamp to distribute force more evenly when tightening. The softness and elasticity of the plastic handle can absorb part of the impact force generated during tightening, avoiding damage to the pipe or the hose clamp itself. At the same time, the grip of the plastic handle also makes it easier for the user to control the tightening force and ensure that the hose clamp is properly tightened on the pipe.

When installing the hose clamp, it is necessary to ensure that the hose clamp is tightened to the appropriate degree. Too tight may cause damage to the pipe or the hose clamp itself, while too loose will not form a tight seal. Therefore, appropriate tools and methods need to be used during the installation process to measure and adjust the tightening degree of the hose clamp. When tightening the hose clamp, it is necessary to ensure that the force is evenly distributed over the entire circumference of the hose clamp. This can be achieved by using a dedicated hose clamp pliers or wrench. Uniform force can avoid deformation or leakage of the hose clamp due to uneven force. In order to ensure the long-term stability and sealing of the hose clamp, the status of the hose clamp needs to be checked and maintained regularly. This includes checking whether the hose clamp is loose, damaged or corroded, and whether a new hose clamp needs to be replaced.

American plastic handle hose clamps are widely used in many fields, which have extremely high requirements for the sealing and safety of pipeline connections. In automobile manufacturing, American plastic handle hose clamps are widely used in pipeline connections in key parts such as fuel systems, cooling systems, and braking systems. These systems have extremely high requirements for sealing and safety, and the excellent performance of American plastic handle hose clamps has been widely recognized and verified. In fire protection systems, American plastic handle hose clamps are used to connect key equipment such as water pipes and fire hydrants. These equipment need to withstand high-pressure water flow and high-temperature environment in emergency situations, and the reliability and durability of American plastic handle hose clamps have been fully verified. In railway systems, American plastic handle hose clamps are used to connect various pipelines and equipment, such as fuel pipes, lubricating oil pipes, etc. These pipelines and equipment have extremely high requirements for sealing and stability, and the excellent performance of American plastic handle hose clamps ensures the safe operation of railway systems.