How does the structural design of the Small American Hose Clamp ensure sealing and prevent leakage?

2025.06.27

2025.06.27

Industry News

Industry News

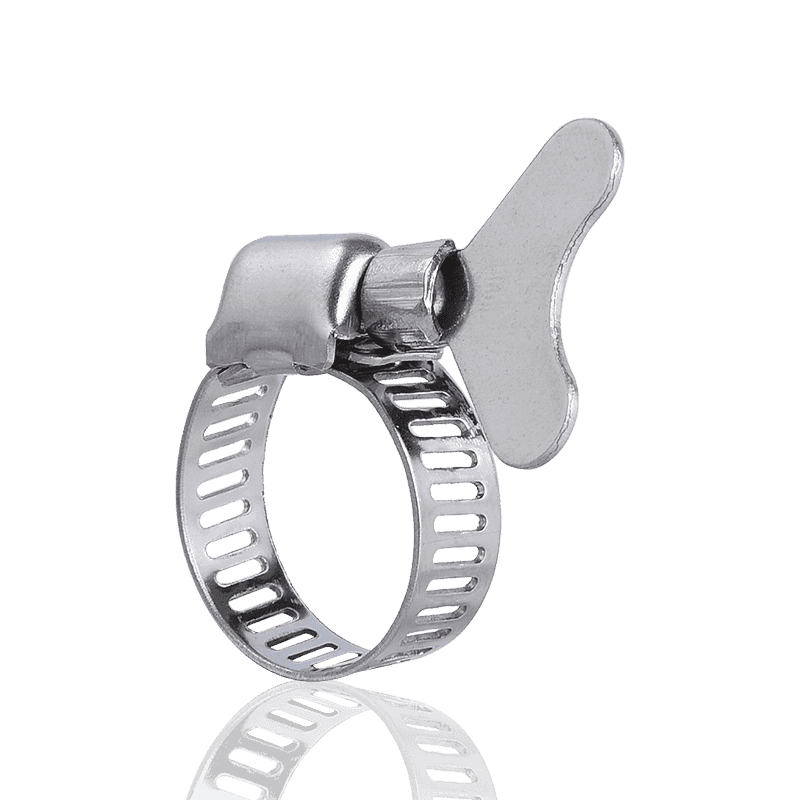

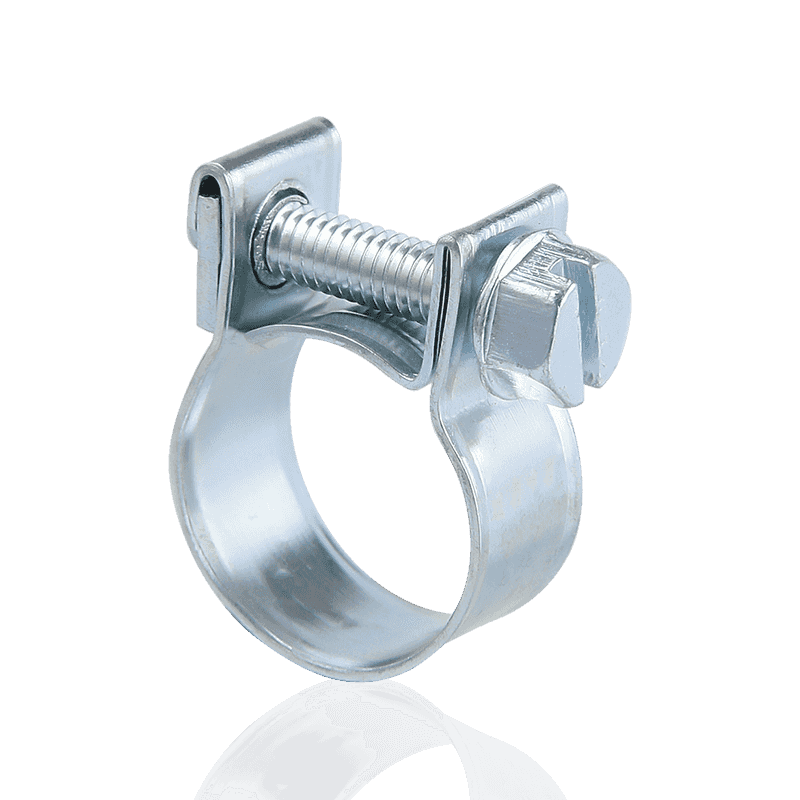

The Small American Hose Clamp is a fastening element designed for connecting hoses and pipes. The Small American Hose Clamp adopts a steel belt through-hole process, and the screws and the steel belt are tightly engaged to ensure the fastening force and sealing. This structure not only improves the torsion resistance and pressure resistance, but also facilitates installation and adjustment.

Through-hole process: The steel belt of the throat clamp adopts a through-hole design, so that the screws can be tightly engaged with the steel belt, thereby enhancing the fastening force and sealing. This structure not only improves the torsion resistance and pressure resistance, but also ensures the stability when connecting pipes of different diameters.

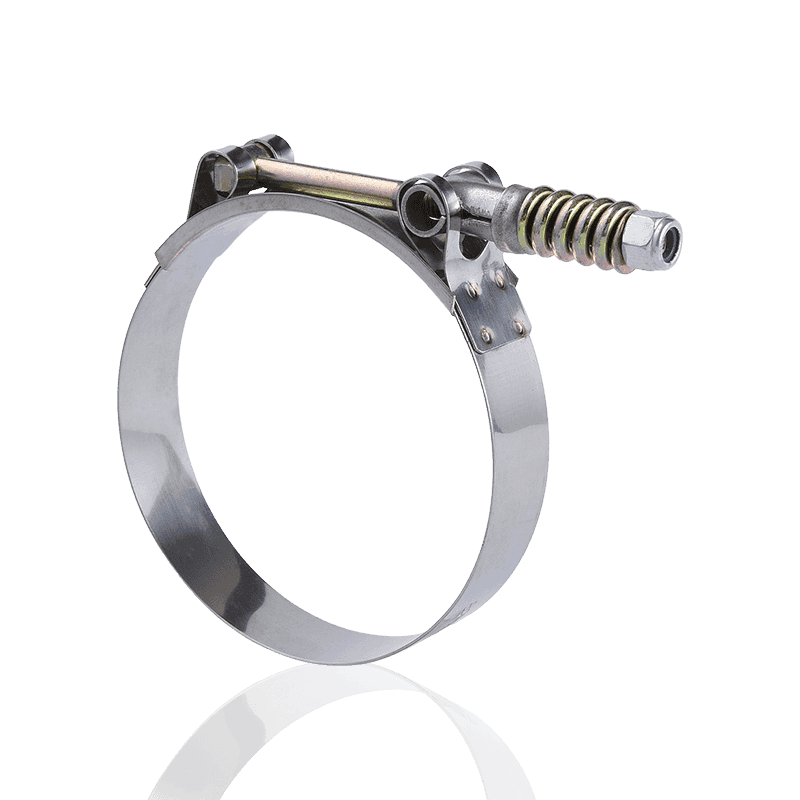

Open inner and outer ring structure: The American throat clamp adopts an open inner and outer ring structure and is fastened by bolts. This design effectively solves the dead angle problem when connecting small diameter soft and hard pipes, and avoids the leakage of liquids and gases.

Uniform pressure distribution: The structural design of the throat clamp makes the pressure evenly distributed around the entire hose, which helps to avoid the hose from being damaged due to uneven pressure at the interface, while ensuring good sealing performance to prevent liquid or gas leakage.

Sealing design: The screw of the throat clamp is designed as a right-hand single-start thread to ensure reliable engagement with the connected parts. The screw is firmly engaged with the steel belt, and the movable end of the steel belt can be disengaged when necessary, which is convenient for assembly or movement while maintaining sealing.

Material selection: Small American Hose Clamps are usually made of stainless steel (such as 304, 316 stainless steel), which has good corrosion resistance and pressure resistance, and is suitable for harsh environments such as chemical corrosion, vibration, extreme temperature, etc.

Adjustment mechanism: The throat clamp is equipped with a simple adjustment mechanism, which is tightened or loosened by a simple screw mechanism, so that users can easily adjust the tightness of the throat clamp to adapt to hoses or pipes of different sizes, thereby ensuring sealing.

Surface treatment: The surface of the throat clamp is specially treated (such as polishing), which not only improves the aesthetics, but also enhances its corrosion and rust resistance, and prolongs its service life.