How to use the German quick-release clamp correctly to ensure its stable performance?

2025.06.20

2025.06.20

Industry News

Industry News

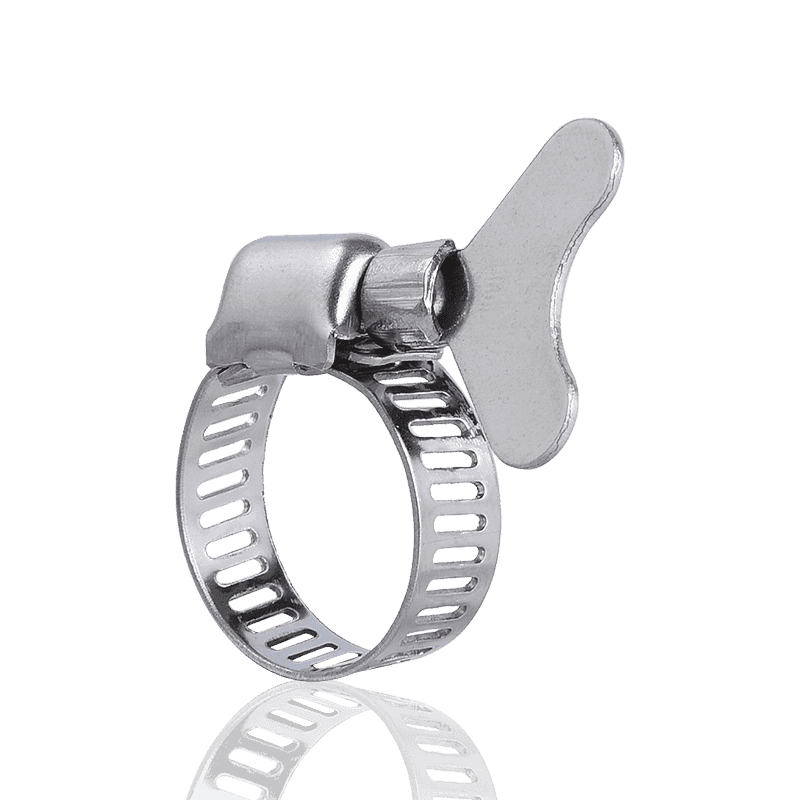

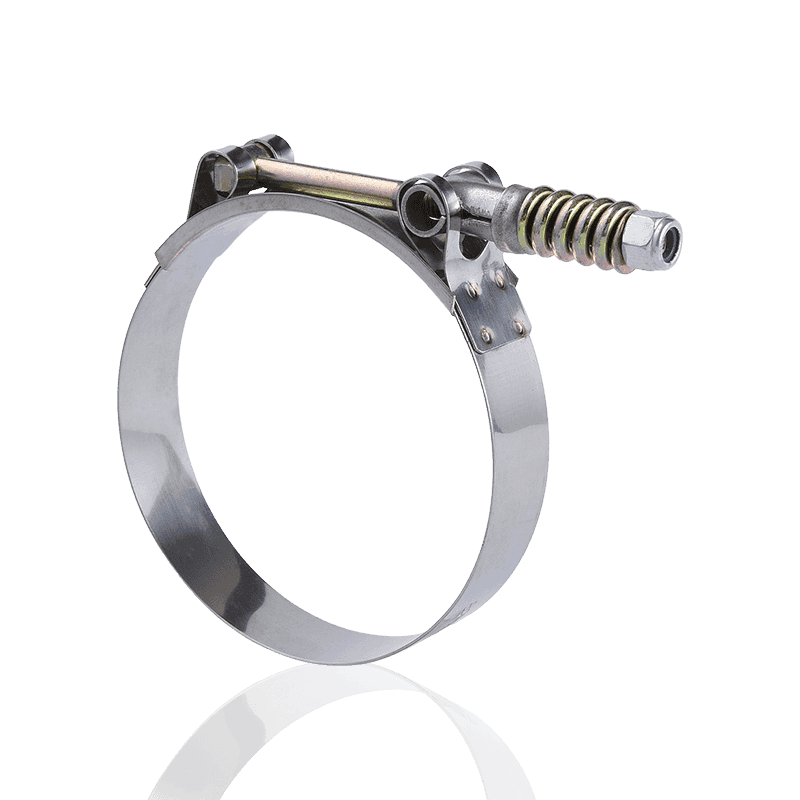

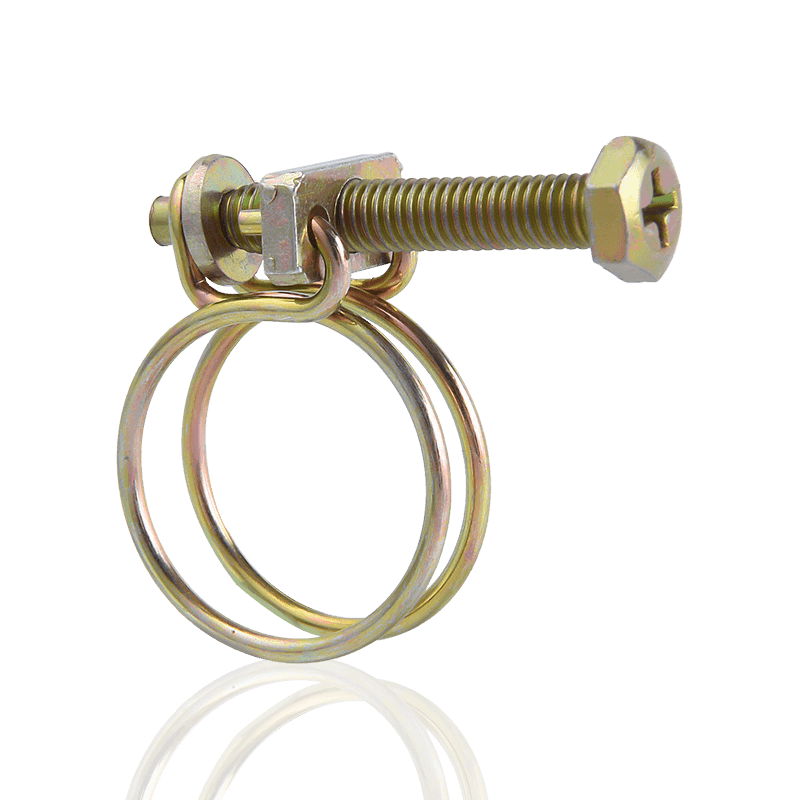

The German quick-release clamp (German quick-release clamp) is a fastening device that uses a high-precision manufacturing process. The main body is made of 430 stainless steel strip, the clamp head is nickel-plated, and the screws are galvanized. It has excellent anti-rust and corrosion resistance. Its quick-release mechanism design can achieve quick installation and removal, and is suitable for fixing scenes such as hoses, cables, and light machinery. To ensure its long-term stable operation, it is necessary to follow the correct use and maintenance methods.

Inspection before installation

Check the clamp body status: Make sure that the steel strip is not deformed or cracked, and the clamp head and screws are not rusted or worn.

Confirm the applicable scenario: The German quick-release clamp is suitable for fixing hoses, cables, light mechanical parts, etc., and avoid overload use (such as heavy machinery fastening).

Matching size: Choose a clamp of the appropriate size to ensure that it fits tightly with the fixed object to avoid deformation caused by looseness or overtightening.

Correct installation steps

Align the fixed position: Wrap the steel belt of the quick-release clamp around the object to be fixed (such as hoses, wiring harnesses) to ensure uniform force.

Adjust the tightness: Manually pre-tighten the screws to initially fix the steel belt, but do not completely lock it. Use a screwdriver (or manually) to slowly tighten until the clamp is stable but does not crush the fixed object.

Use of quick release mechanism: If you need to disassemble quickly, press or toggle the quick release button (depending on the specific model) to easily loosen the clamp without completely removing the screws. When reinstalling, just align and tighten. Some models support "one-click locking".

Precautions in use

Avoid overtightening: Overtightening the screws may cause the steel belt to deform, reduce the clamping force or damage the fixed object.

Anti-corrosion maintenance: After use in high humidity, salt spray or chemical environments, it is recommended to wipe with a dry cloth to prevent residual corrosive substances from affecting the coating. If exposed to harsh environments for a long time, anti-rust oil can be applied regularly to extend the life.

Regular inspection: Check whether the screws are loose and the chuck is worn at regular intervals to ensure stable clamping force. If the coating is found to be peeling or rusted, it should be replaced in time to avoid affecting performance.