How to Accurately Measure and Select Hose Clamp Specifications?

2026.01.23

2026.01.23

Industry News

Industry News

The most crucial step in accurately measuring and selecting hose clamps specifications is measuring the "maximum outer diameter (O.D.)" of the hose after installation. Many users mistakenly purchase hose clamps based on the nominal inner diameter of the hose, which often leads to a size mismatch. The correct approach is to fully insert the hose into the fitting (such as a barbed fitting or aluminum pipe) and then use a caliper to measure the circumference or diameter at the thickest part of the connection. The selected hose clamp specification range must ensure that this measured value falls between its "minimum diameter" and "maximum diameter," and ideally, it should be in the middle of the range to achieve optimal tightening torque.

Three Steps to Measurement Before Purchasing Hose Clamps

In industrial maintenance or automotive repair, choosing the wrong hose clamp size can lead to minor issues like leaks or major problems like hose detachment. Please follow this professional measurement process:

1. Simulate the Actual Installation State

Do not measure the hose in its natural state. Because hoses are elastic and the fitting will expand the pipe wall after insertion, the measurement must be taken after the hose is fitted onto the connector. This value is called the installed outer diameter.

2. Use Professional Measurement Tools

It is recommended to use a caliper for multi-point measurement and take the average. If a caliper is not available, you can wrap a thin string around the pipe to measure the circumference, and then use the formula Diameter = Circumference / 3.14 to calculate the diameter.

3. Allow for Tightening Margin

When selecting stainless steel hose clamps, avoid the extreme values of the specifications. For example, if the measured outer diameter is 26mm, although both 25-38mm and 16-27mm specifications can cover it, choosing 25-38mm is safer because 27mm is close to the upper limit, and insufficient screw adjustment margin may result in insufficient tightening force.

Common Hose Clamp Specifications and Bandwidth Selection

In addition to diameter, the bandwidth of the hose clamp is also a key factor affecting the sealing effect.

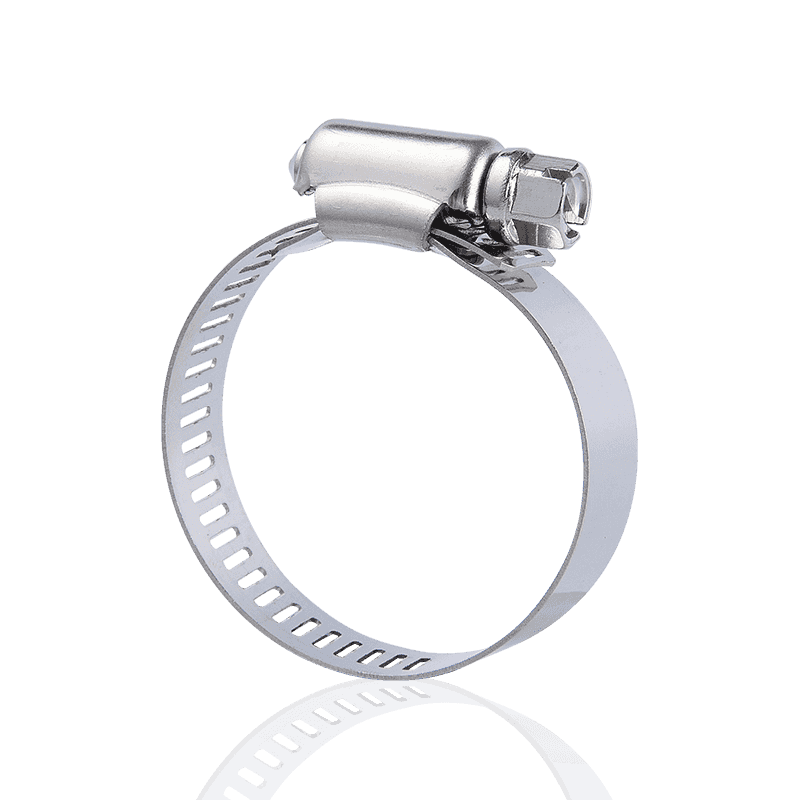

Small diameter hoses (such as fuel lines, vacuum lines): Usually, American-style hose clamps with a bandwidth of 8mm or 9mm are used. The narrower steel band can concentrate greater pressure in a smaller area.

Medium to large diameter hoses (such as radiator hoses, ventilation ducts): We recommend choosing heavy-duty hose clamps with a bandwidth of 12.7mm or 14.2mm. The wider contact area effectively prevents the hose from being cut and provides a more even 360-degree seal.

Why choose high-quality stainless steel hose clamps?

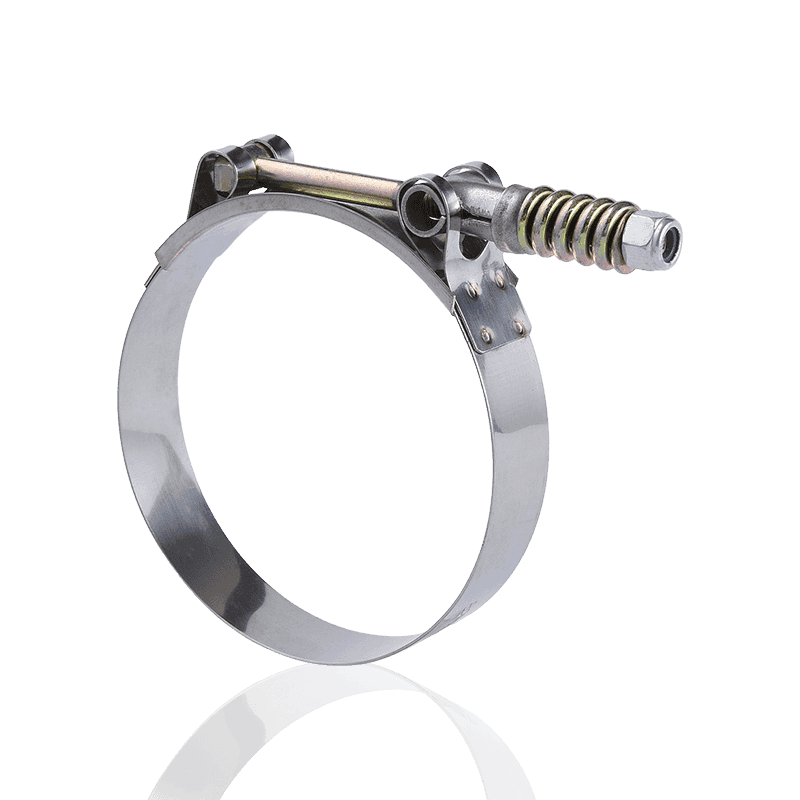

As a professional clamp manufacturer, we recommend prioritizing 304 or 316 stainless steel hose clamps in any high-pressure or outdoor environment.

Corrosion resistance: High-quality stainless steel hose clamps resist corrosion from rain, coolant, and engine oil, preventing screw rusting that could make removal difficult.

Fatigue strength: High-strength steel bands are less likely to loosen in environments with alternating hot and cold temperatures (such as engine compartments), maintaining long-term clamping pressure.

Precision manufacturing: Qualified hose clamp edges should be flanged or polished to ensure that they do not scratch the surface of expensive hoses during tightening.

When purchasing hose clamps, remember: "Measure the outer diameter, check the material, and choose the bandwidth." A properly sized hose clamp not only provides a perfect seal but also extends the service life of the hose and reduces future maintenance costs.