What are some common problems with hose clamps?

2026.01.16

2026.01.16

Industry News

Industry News

In industrial manufacturing, automotive repair, and everyday household plumbing systems, hose clamps, as seemingly small but crucial fasteners, play a core role in preventing liquid or gas leaks. However, due to improper selection or incorrect installation, users often encounter various troublesome problems during use.

I. Common Faults and Problems with Hose Clamps

1. Leakage at the Sealing Surface (Poor Sealing)

This is the most common problem. Even with hose clamps installed, leaks may still occur at the joint.

Cause Analysis: This is usually because the clamp specifications do not match the hose's outer diameter, resulting in uneven tightening force; or the hose has aged and hardened, preventing the clamp from generating sufficient radial pressure.

Solution: Ensure that you select stainless steel clamps with accurate dimensions and check if the hose needs replacement.

2. Clamp Breakage or Stripped Threads

During installation, excessive force often leads to clamp breakage or stripped threads on the worm gear screw.

Cause Analysis: The installation torque exceeded the clamp's load-bearing limit, or inferior carbon steel material was used, resulting in insufficient corrosion resistance and strength.

Solution: It is recommended to use a torque wrench for standardized installation and prioritize high-strength American or German-style clamps.

3. Corrosion and Rusting

Ordinary clamps are prone to rusting in humid, acidic, alkaline, or salt spray environments.

Cause Analysis: Incorrect material selection. For example, galvanized material was used instead of 316 stainless steel hose clamps in marine environments or chemical pipelines.

Solution: Select the appropriate corrosion resistance level according to the usage environment; stainless steel is the preferred material for outdoor and corrosive environments.

4. Hose Cutting Damage

Some inferior clamps have sharp edges that can cut into the hose during tightening, causing damage to the hose wall.

Cause Analysis: The clamp edges were not flanged.

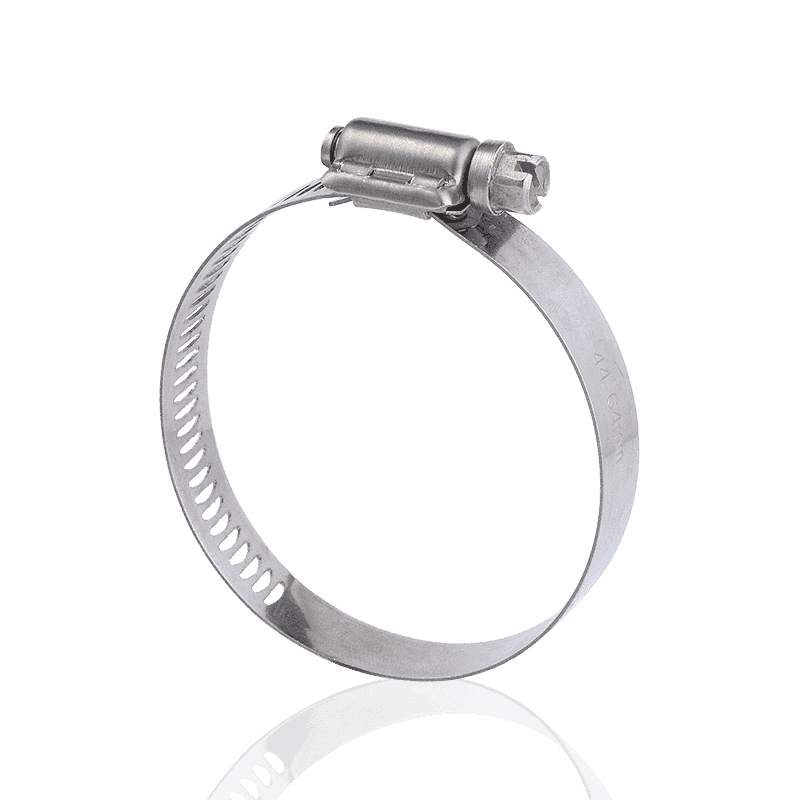

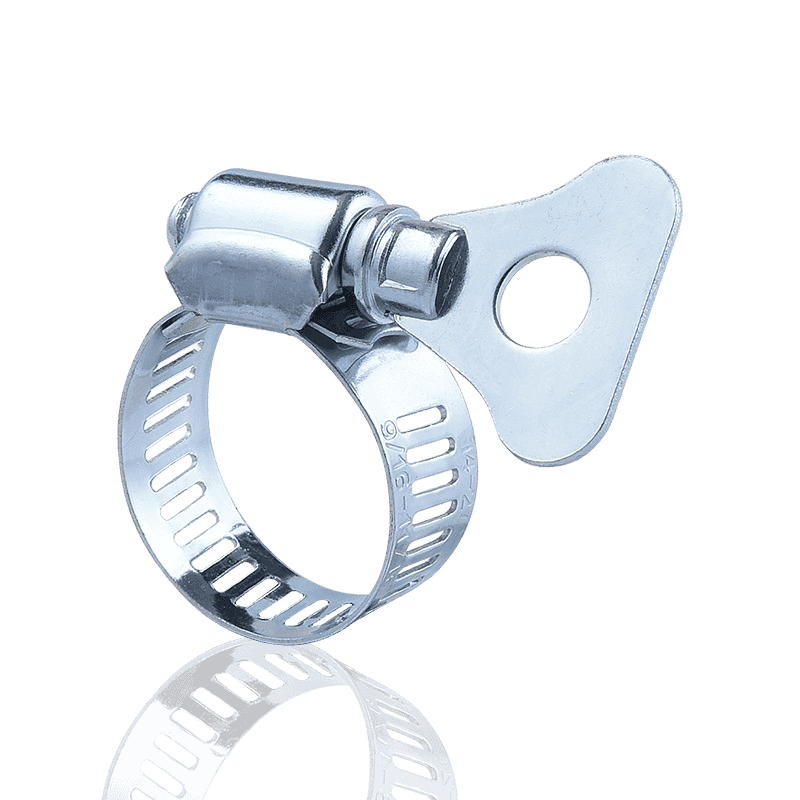

Solution: Choose German-style hose clamps with flanged edges; this design effectively protects the hose surface from scratches.

II. How to Correctly Select Hose Clamps?

- Material Selection (304/316 Stainless Steel): High-grade stainless steel is preferred to ensure excellent oxidation resistance in humid or corrosive environments, preventing fastening failure due to rust.

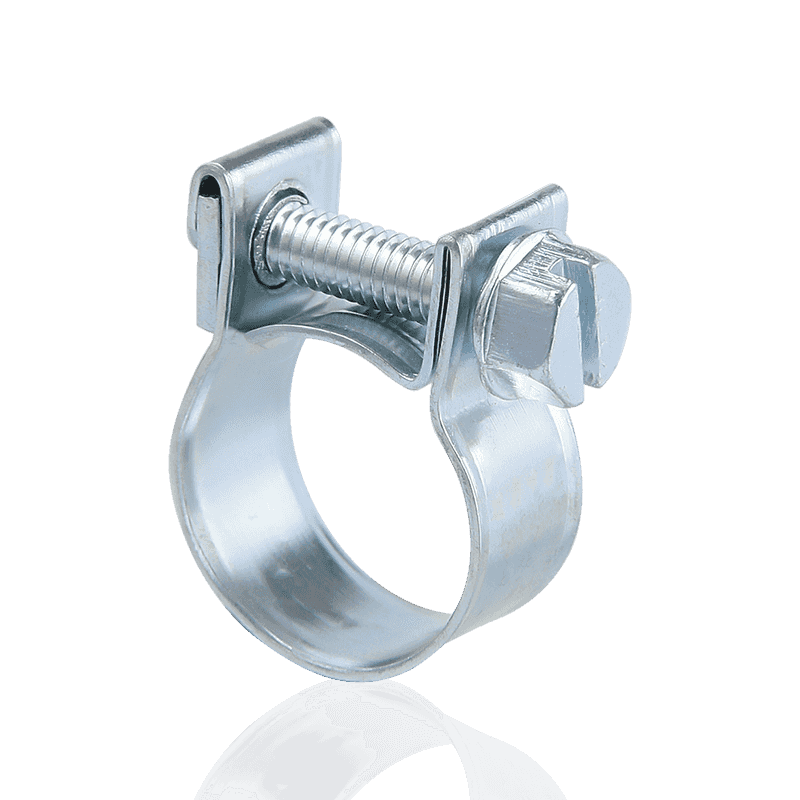

- Width Specifications (Matched by Pressure): The width is determined by the pipe pressure. Wide bands provide a larger clamping contact area and more even pressure distribution; narrow bands are more suitable for confined spaces.

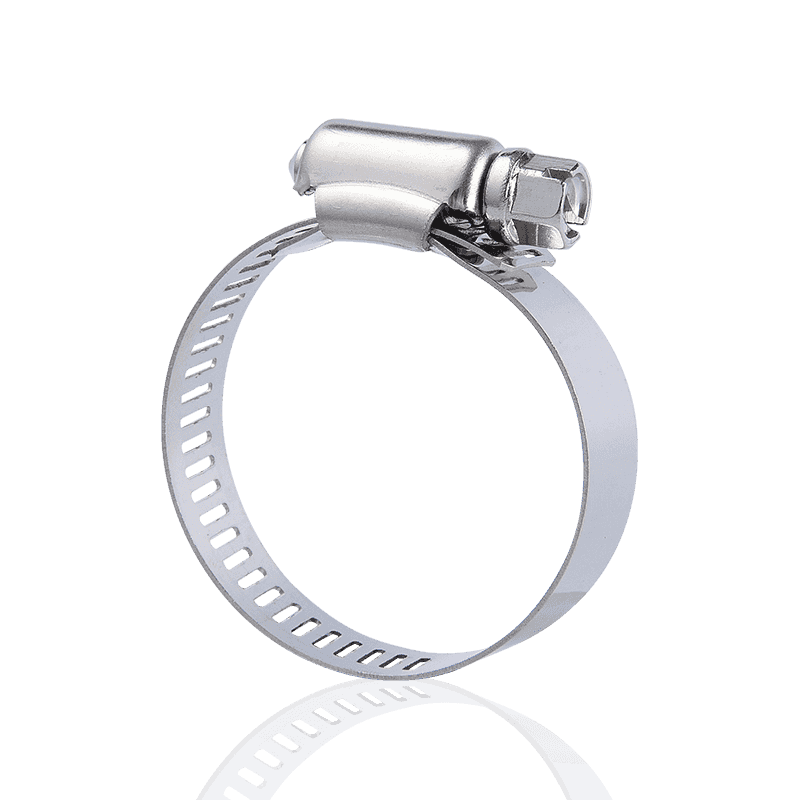

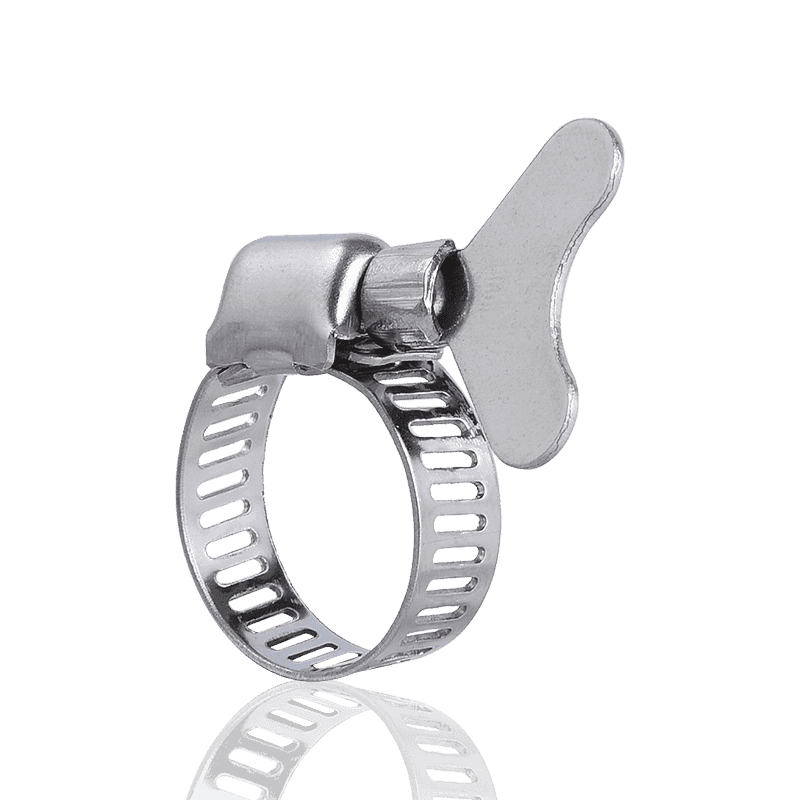

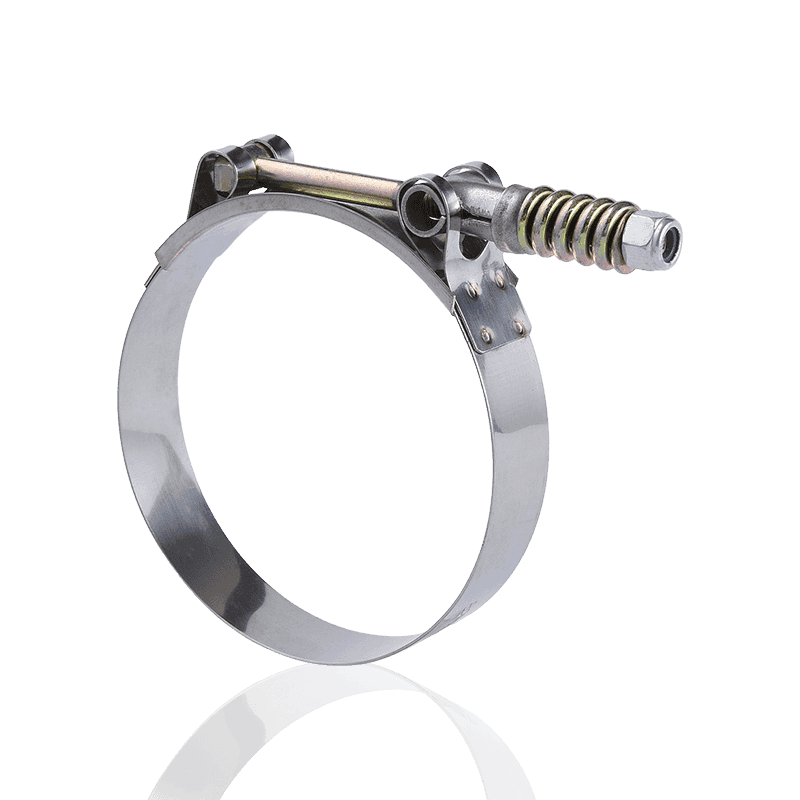

- Structure Type (Worm Gear vs. Heavy-Duty): Worm gear drives are versatile and have a wide adjustment range; for high-pressure environments or thick-walled rigid pipes, heavy-duty clamps are recommended for higher tightening force.

- Manufacturing Standards (DIN vs. ANSI): DIN clamps have a flanged body to effectively protect the hose from scratches; ANSI clamps are characterized by high torque and are suitable for applications requiring extremely high tightening strength.

III. Secrets to Extending the Service Life of Hose Clamps

- Regular Inspection: On equipment with significant vibration (such as engines), hose clamps may loosen due to vibration; regular checks of the tightness are necessary.

- Oversized Use is Strictly Prohibited: Do not attempt to forcibly enlarge small-sized clamps, as this will damage their structural integrity.

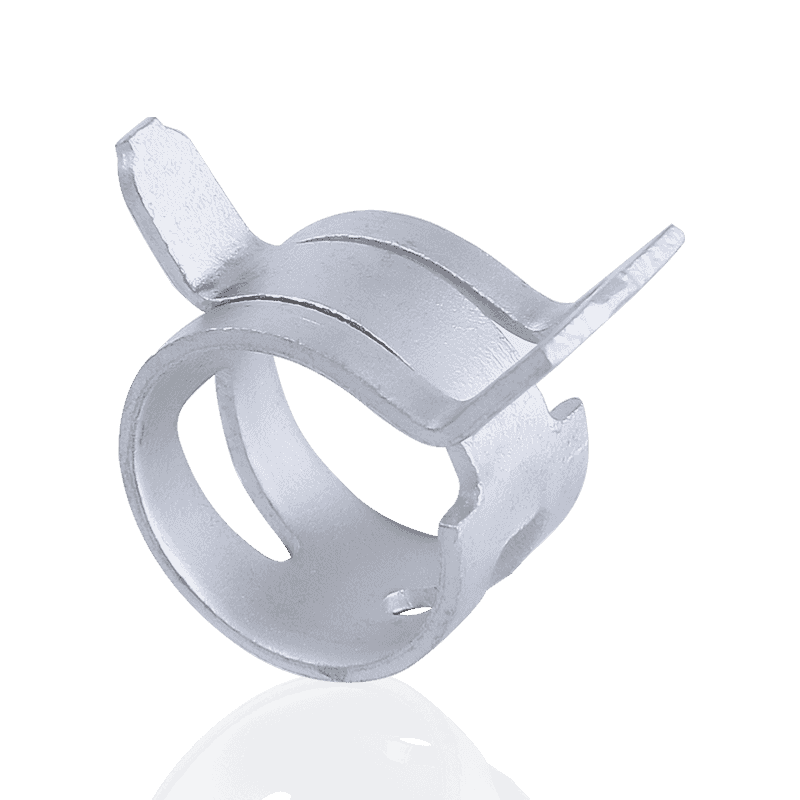

- Consider Environmental Temperature Variations: Extreme high and low temperature cycles can cause thermal expansion and contraction of materials; therefore, it may be necessary to select flexible, constant-pressure clamps.

Although small, hose clamps are crucial to the safe operation of the entire system. Understanding common problems and mastering the correct selection and installation methods can effectively avoid leakage risks and reduce maintenance costs.

When using in critical areas (such as fuel lines or high-pressure water pipes), always ensure you use high-quality brand hose clamps; do not risk serious consequences for minor inconveniences.