How to Maintain Hose Clamps?

2025.11.21

2025.11.21

Industry News

Industry News

The Importance and Necessity of Hose Clamp Maintenance

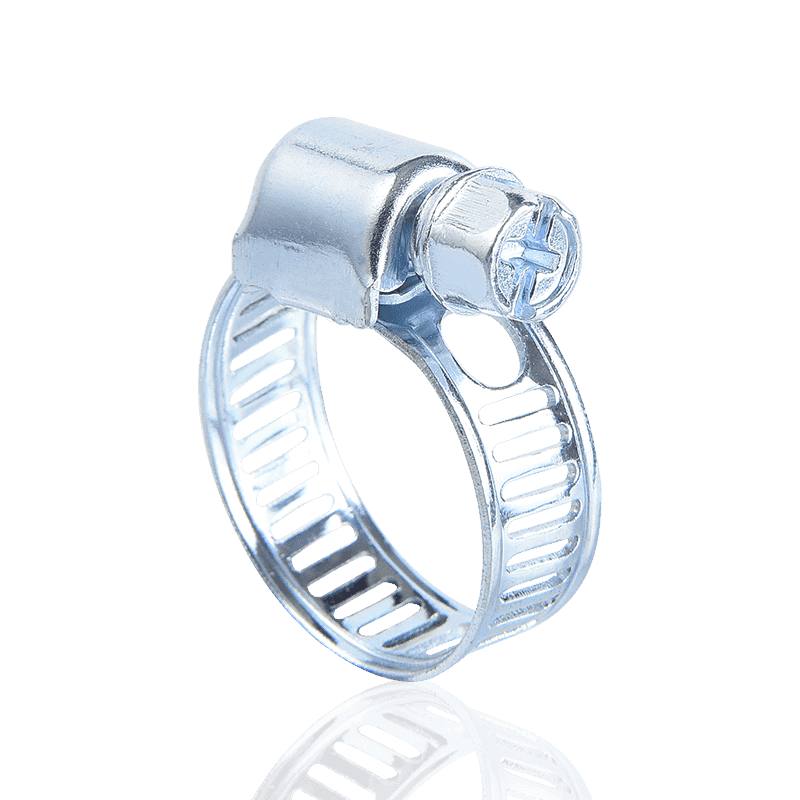

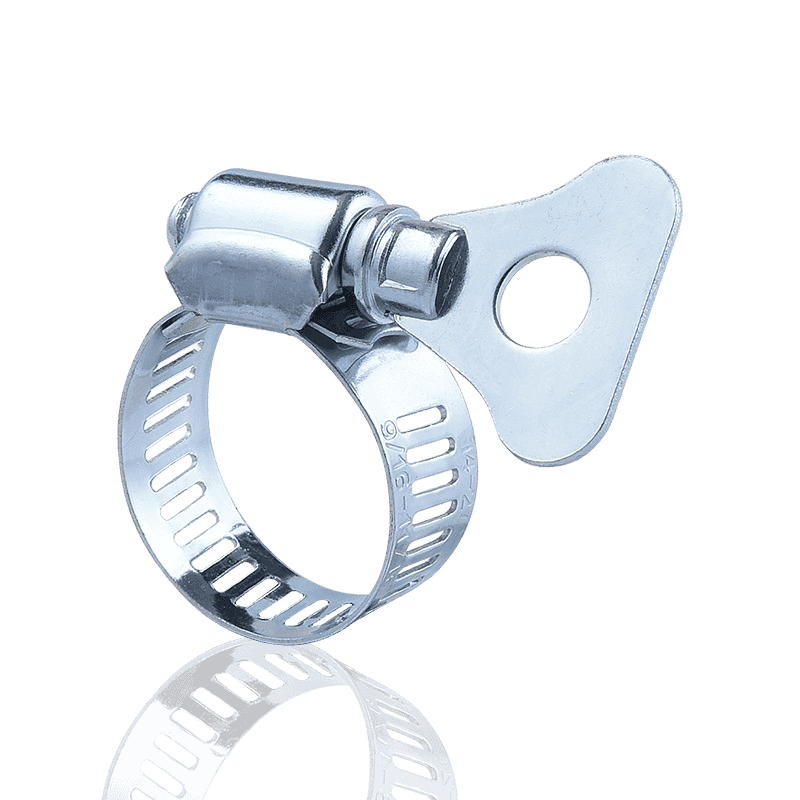

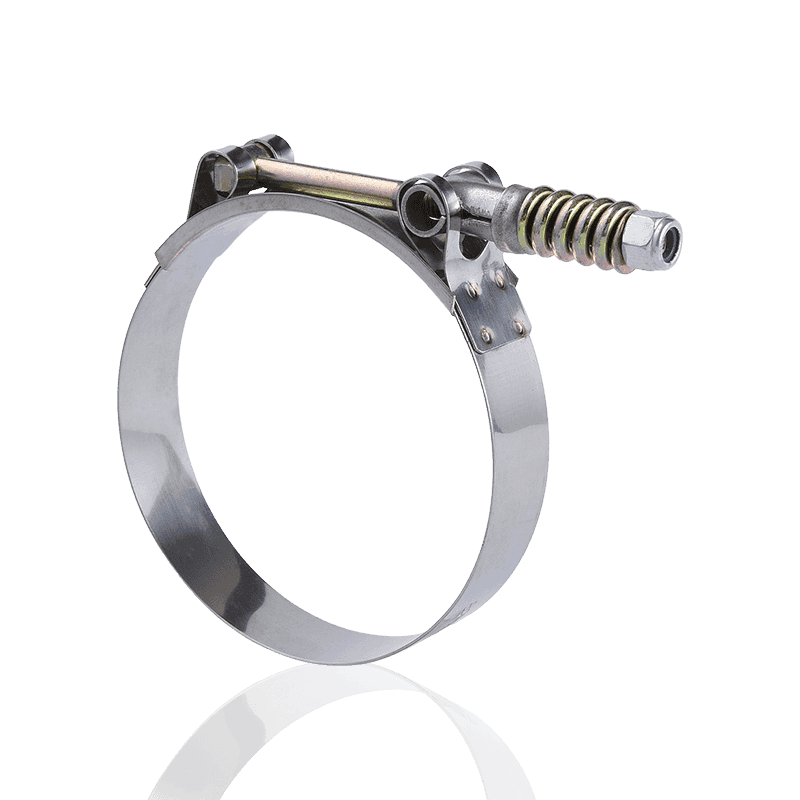

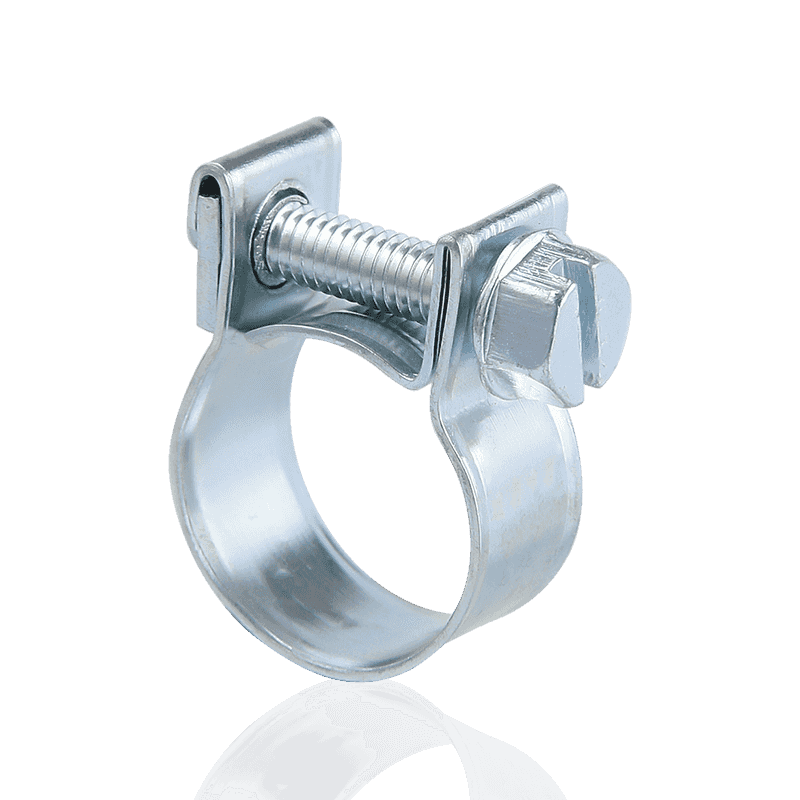

In many fluid transport systems, hose clamps (also widely known as hose reels) are crucial fasteners responsible for securely connecting hoses to fittings or interfaces, ensuring seals and system integrity. Whether in automobiles, industrial machinery, or water treatment equipment, the reliability of hose clamps directly impacts system safety and efficiency.

However, these metal clamps operate for extended periods in environments with vibration, temperature variations, humidity, or chemical exposure, making them prone to loosening, corrosion, or damage. Therefore, scientific and systematic maintenance is essential for extending the lifespan of hose clamps and ensuring equipment durability.

I. Regular Inspection: Key to Identifying Potential Problems

The first step in maintenance is establishing a rigorous regular inspection process. The frequency of inspections should be determined based on the severity of the environment in which the hose clamps operate.

1. Visual Inspection Points

Corrosion: Carefully inspect the steel band, bolts, and housing of the hose clamps for rust or oxidation. Severe corrosion significantly weakens the strength of the metal clamps.

Physical Damage: Check the hose clamps for cracks, deformation, excessive wear, or stripped threads. 1. Contact with the hose: Ensure the edges of the fasteners are not embedded in or cutting into the hose surface, as this can cause premature hose failure.

2. Tightness Test: Gently move the hose by hand to test for looseness. If displacement or leakage is found, it must be retightened or replaced immediately.

II. Corrosion Resistance: Enhancing Hose Clamp Durability

Corrosion prevention is central to hose clamp maintenance, especially for applications in outdoor, humid, or high-salt-spray environments.

Material Selection and Maintenance:

When purchasing, prioritize hose clamps made of high-quality stainless steel (such as 304 or 316) for superior corrosion resistance.

For non-stainless steel metal clamps, after cleaning, apply a professional anti-rust grease to bolts and threads, forming a protective layer.

Environmental Cleaning:

Regularly remove dirt, grease, and potentially corrosive residues from the hose clamps. Wipe with a mild detergent and a soft cloth.

III. Precise Torque Control: Avoid Over- or Under-Tightening

Incorrect torque is one of the main causes of hose clamp failure and hose damage.

Insufficient torque: Inability to create effective sealing pressure, leading to liquid or gas leaks.

Excessive torque: Can cause permanent deformation or even breakage of the steel band or bolts on the hose clamp, while also excessively compressing and damaging the hose's material structure, shortening its lifespan.

Professional Recommendation:

Always use a calibrated torque wrench for installation and adjustment.

Strictly follow the recommended torque value provided by the hose clamp manufacturer. This value is the key balance point for ensuring sealing effectiveness and fastener structural safety.

IV. Replacement Timing and Proper Installation

If the hose clamp shows severe corrosion, deformation, or thread wear, it should be replaced immediately, rather than attempting repair.

Matching:

Ensure the size and type of the newly replaced hose clamp matches the hose and its operating environment.

Proper Installation:

During installation, ensure the metal clamp is evenly fitted over the hose-fitting connection, avoiding angled placement or partial suspension. This helps maximize connection durability and sealing.

Systematic inspection, corrosion protection, and torque management of hose clamps are essential investments to ensure their durability and safe system operation. Incorporate these steps into your equipment maintenance plan to guarantee the stable and reliable operation of your fluid systems.