How to Choose the Right Hose Clamp?

2025.11.14

2025.11.14

Industry News

Industry News

Hose clamps, also commonly known as hose clamps, are key components for connecting and securing fluid transport systems such as hoses, water pipes, and oil pipes. In many fields, including automotive, industrial, water treatment, and chemical industries, the reliability of hose clamps directly affects the operating efficiency and safety of equipment.

Understanding Hose Clamp Types and Applications

Before selecting, it's essential to understand the main types of hose clamps and their characteristics:

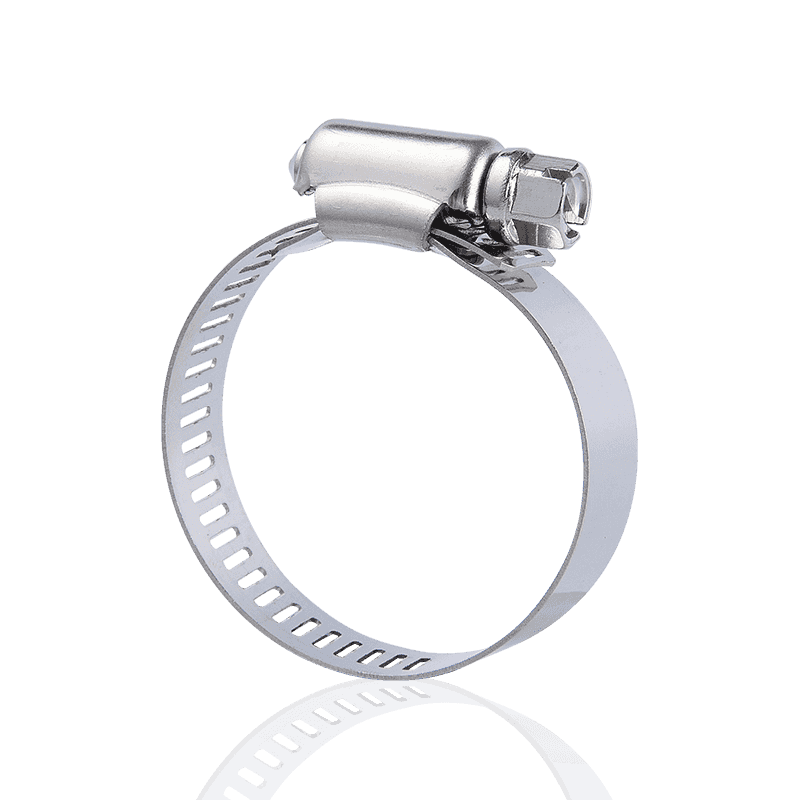

1. Threaded Hose Clamps (American/German)

American Hose Clamps (Through-Hole): These feature a perforated band and screw engagement design. As described in your product introduction, American hose clamps utilize a through-hole process, resulting in balanced torque, a secure lock, and a wide adjustment range, making them suitable for fastening both flexible and rigid pipes. However, their tensile strength is slightly weaker than that of German hose clamps.

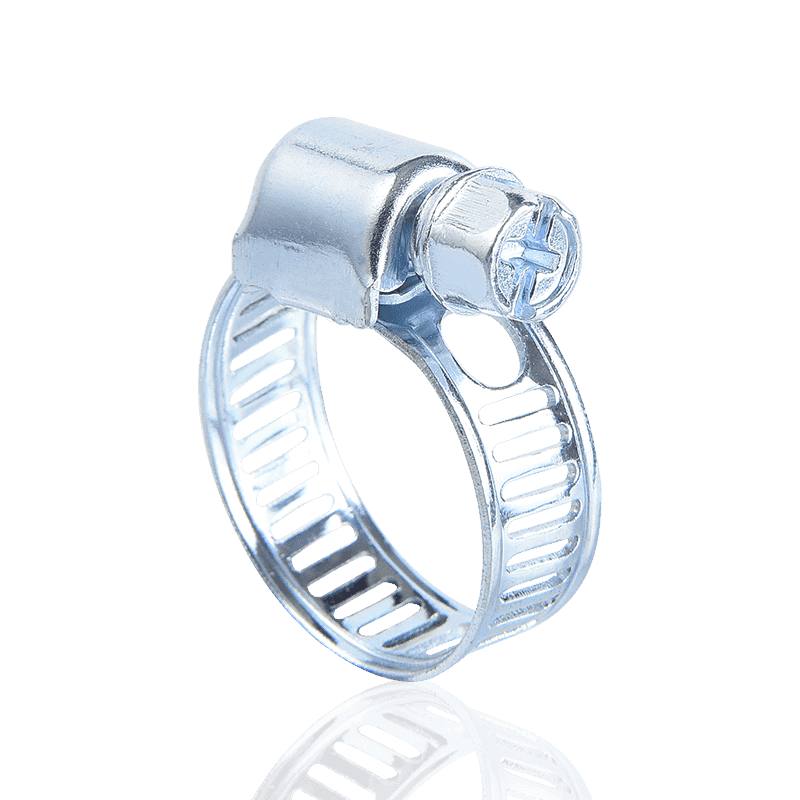

German Hose Clamps (Stamped/Non-Through-Hole): These typically offer higher lateral pressure resistance and a smoother inner wall, making them suitable for applications requiring higher sealing performance or where the hose material is softer.

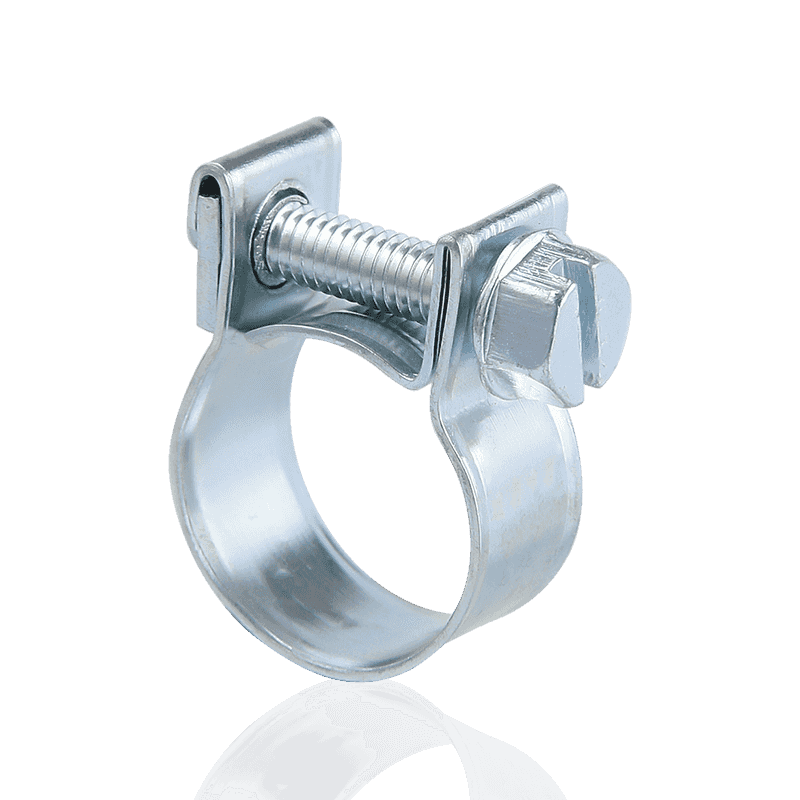

2. Heavy-duty hose clamps

Suitable for industrial applications requiring high pressure, large diameter, or resistance to significant mechanical stress.

3. T-bolt hose clamps

Provide very high locking force and uniform radial pressure, commonly used in truck intake systems and turbocharger connections.

Key Selection Considerations

To ensure your chosen hose clamp meets your application needs, consider the following key factors:

1. Application Environment and Material Selection

The material of the hose clamp is crucial to its durability. When selecting, match the appropriate material to the specific application environment to ensure reliable operation. Your product material options include premium stainless steel and carbon steel.

Wet/Corrosive Environments:

- Recommended Material: Premium stainless steel (e.g., 304, 316).

- Suitable Applications: Marine, water treatment systems, chemical machinery, outdoor applications. In these environments, stainless steel effectively resists corrosion, ensuring long-term stability and leak-proof performance.

Standard/Dry Environments:

- Recommended Material: Carbon steel (usually requires galvanizing or other surface treatments).

- Suitable Applications: General industrial piping, dry indoor machinery. Carbon steel offers a cost advantage and is suitable for non-corrosive or low-corrosive environments.

Extreme Temperature Environments:

- Recommended Materials: Special alloys or high-grade stainless steel.

- Suitable Applications: Water pumps, diesel engines, high-temperature or low-temperature liquid piping. Choosing a material that can withstand the application temperature range while maintaining mechanical properties is crucial for system reliability.

2. Hose Diameter and Adjustment Range

The selected hose clamp must fit snugly against the hose's outer diameter. Ensure that the adjustment range of the selected hose clamp (e.g., American-style clamps) covers the actual outer diameter tolerance of your hose. Hose clamps that are too large or too small will not provide an effective seal.

3. Tightening Force and Sealing Requirements

For applications subjected to high pressure or vacuum, products that provide higher and more uniform radial tightening force are required, such as T-bolt clamps or well-designed German-style clamps, to ensure leak prevention.

In automotive piping, water pumps, fans, and other equipment, selecting hose clamps with torsional and pressure-resistant properties is essential.

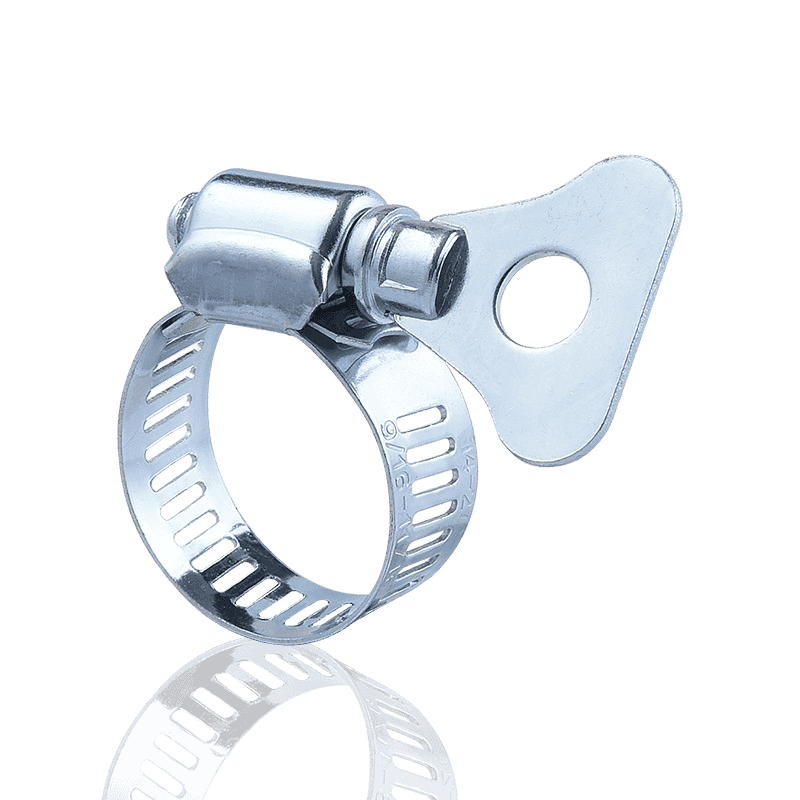

4. Easy Installation and Maintenance

A well-designed hose clamp should be easy to install and remove to reduce maintenance time and costs. For applications requiring frequent installation and removal, hose clamps with handles or easy-to-remove designs are more advantageous.

Choosing the right hose clamp is not a trivial matter; it is fundamental to ensuring the safety, leak prevention, and long-term stable operation of fluid systems. By carefully evaluating the application environment, pressure requirements, and pipe diameter, and matching them according to material and locking characteristics, you can find the most suitable piping connection solution for your needs.