How to Remove a Hose Clamp from a Hose?

2025.11.07

2025.11.07

Industry News

Industry News

In industrial, automotive, and machinery maintenance, correctly and safely removing hose clamps is a crucial step in ensuring the normal operation of equipment. Whether used to secure automotive piping, water pump connections, or pipelines in chemical machinery, hose clamps play a vital role in sealing and securing.

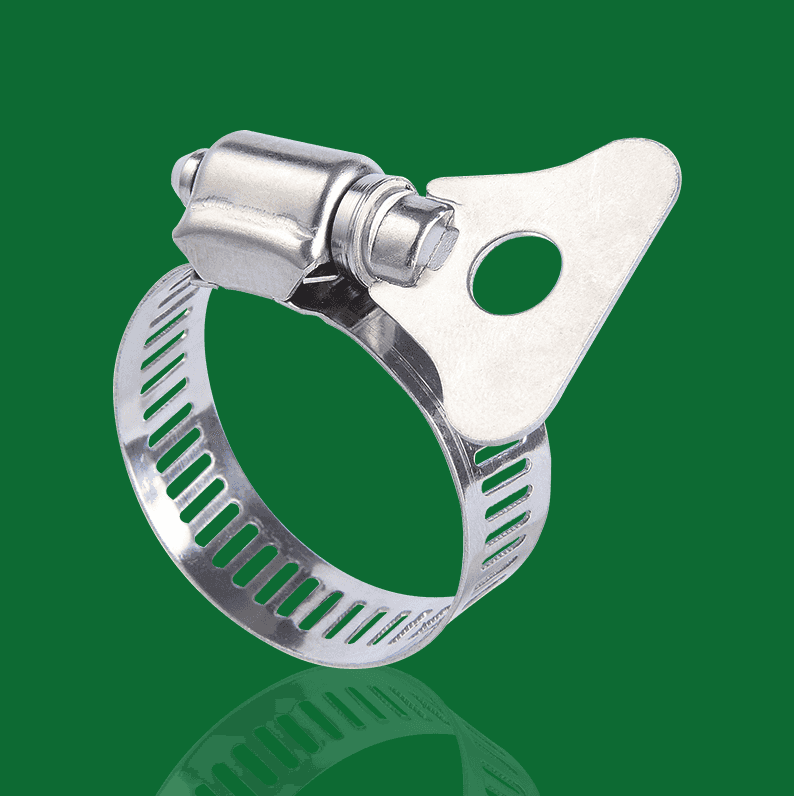

Understanding Your Hose Clamp: Taking an American-Style Hose Clamp as an Example

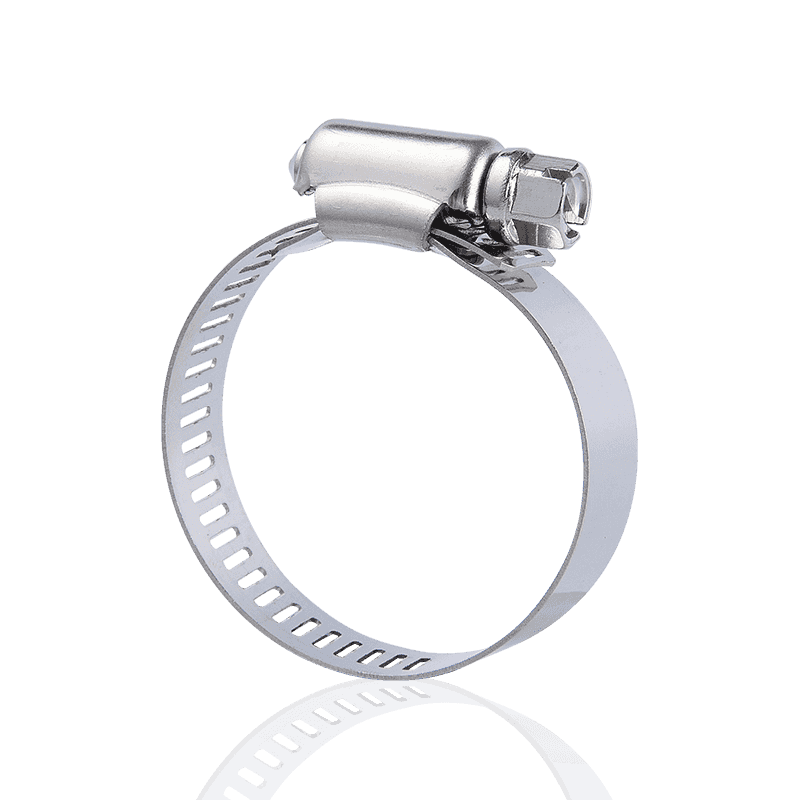

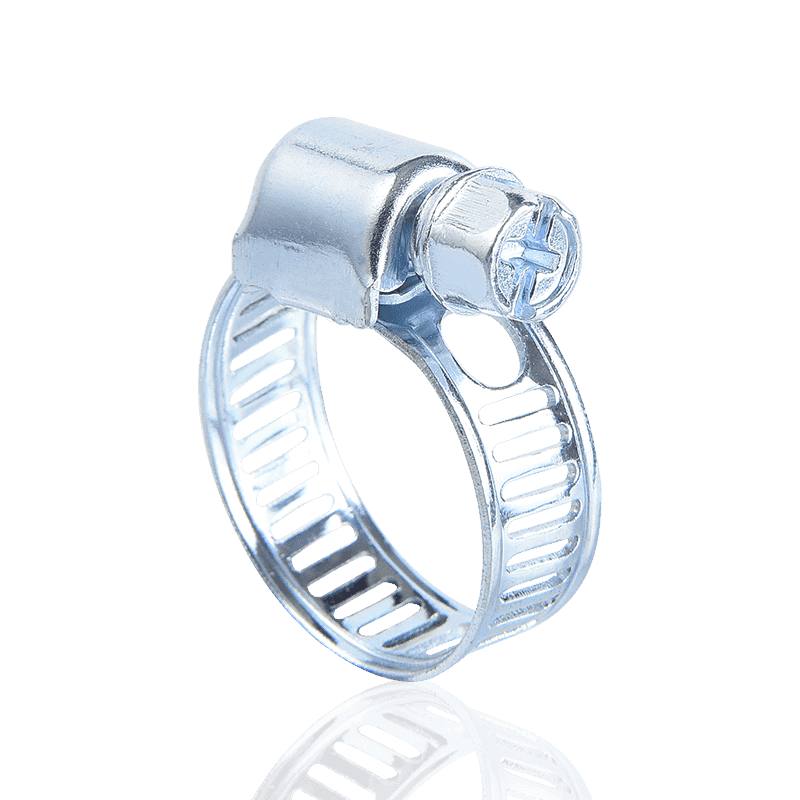

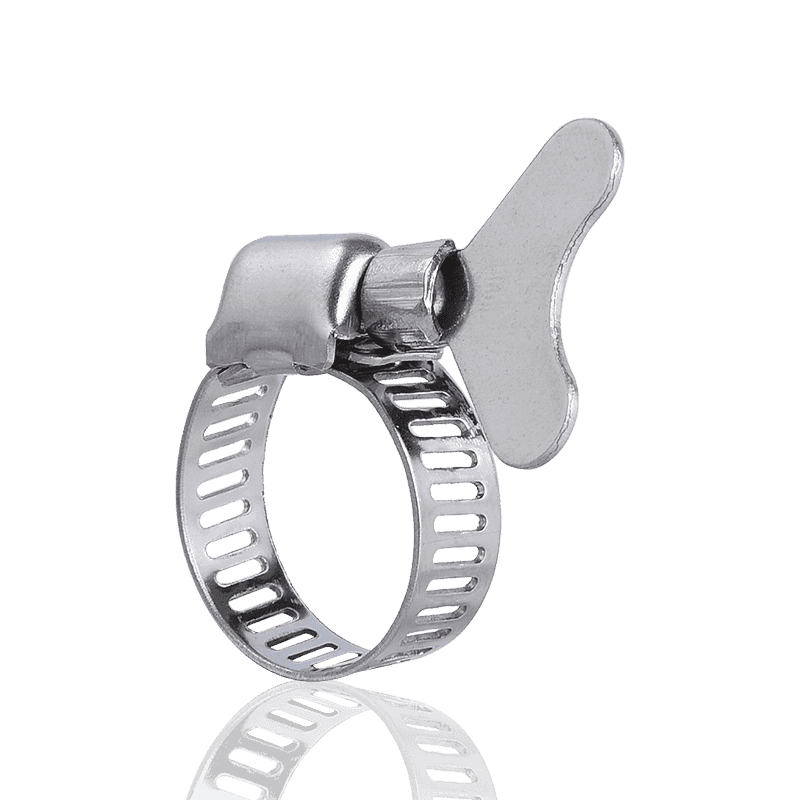

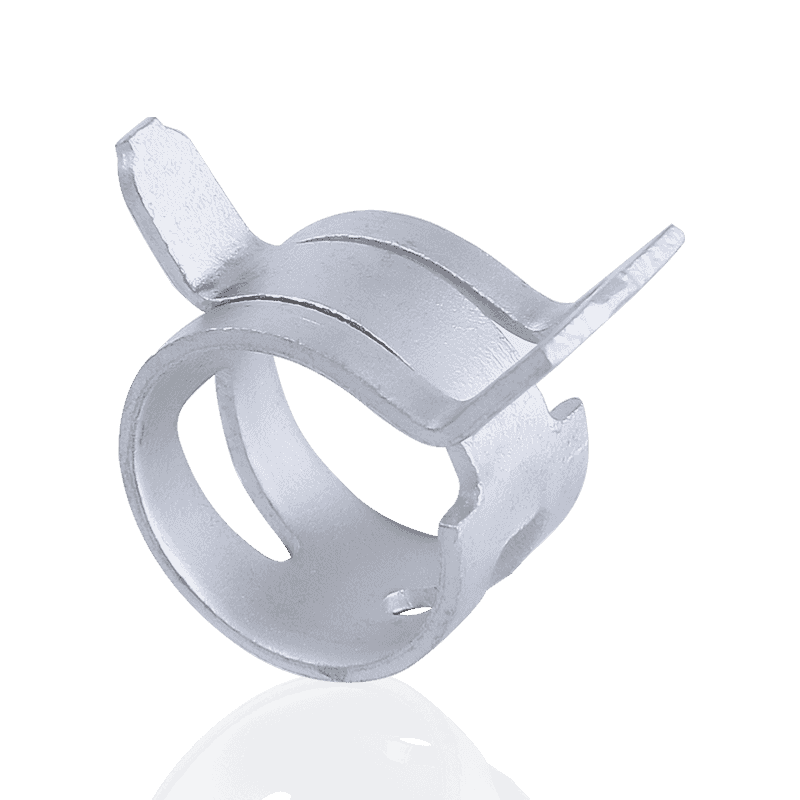

Before you begin removing a hose clamp, it's essential to understand the type of hose clamp you're dealing with. There are many types of hose clamps on the market, the most common being spring-loaded and screw-type (such as American or German-style).

Taking an American-style hose clamp, which you might be maintaining, as an example, its structural feature is that the steel band's interlocking grooves are continuous, providing a balanced locking torque. It typically consists of a metal band ring, a clamp head, and metal screws.

Key Challenge: Due to the strong clamping force of hose clamps, removal requires overcoming this powerful clamping force while avoiding damage to the hose or the clamp itself.

Step One: Preparation and Safety First

Safety is always the top priority. Before performing any disassembly operations, please ensure the following preparations are made:

- Power Disconnection: Ensure the equipment being maintained is completely shut down and disconnect the power supply or medium (such as fuel, coolant, etc.).

- Protective Measures: Wear safety gloves and goggles to prevent injury from loose parts or residual media.

- Tool Preparation: Prepare appropriate tools according to the type of hose clamp. Common tools include:

- Screwdriver (flathead or Phillips head, depending on the screw head type)

- Socket wrench or ratchet wrench

- Hose clamp pliers (for spring-loaded or certain special clamps)

Step Two: Releasing the Hose Clamp – Key Disassembly Techniques

The purpose of releasing the hose clamp is to eliminate its clamping force on the hose.

1. For Screw-Type Hose Clamps (such as American hose clamps)

This is the most common disassembly method:

- Locating Screw: Locate the screw of the American hose clamp (usually hex or flathead/Phillips head).

- Turning Counterclockwise: Using a suitable screwdriver or wrench, turn the screw counterclockwise. You will feel the clamp begin to loosen, at which point the steel band of the American-style hose clamp will gradually open.

- Fully Loosen: Ensure the screw is loosened beyond the hose clamp's adjustment range to completely relax it and prevent it from jamming again when attempting to remove the hose.

2. For Spring-loaded or Clip-on Hose Clamps

- Use Specialized Pliers: Use hose clamp pliers to clamp the jaws and pull the handles outwards to open the two lugs of the clamp.

- Locking: While keeping the clamp open, quickly move the pliers between the hose and the connector, or directly push the clamp away from the edge of the connector.

Step Three: Hose and Connector Separation

Once the hose clamp is fully loosened, the next step is to separate the hose.

- Slight Rotation: Grip the hose firmly and try to gently rotate it left and right a few times at the connector (i.e., along the hose's axis). This helps break the initial adhesion between the hose and the connector (especially any slight "sticking" that may have occurred after prolonged use).

- Apply even force: Grasp the hose near the connector and pull it outwards evenly. Avoid applying excessive force or grasping only the end of the hose, as this may tear it.

- Use a pry bar (with caution): If the hose connection is very tight, very carefully insert a thin, blunt tool (such as a plastic scraper or a thin flathead screwdriver) between the hose and the connector, and gently pry upwards/downwards or outwards to help separate the hose. Caution: Protect the connector surface from damage when prying.

After successfully removing the hose clamp, inspect the hose clamp itself (especially the steel band and threads of American-style hose clamps) for rust or damage. If any damage is found to the hose clamp (fastener), it is recommended to replace it with a new, compliant fastener to ensure a secure and airtight connection in subsequent connections.