What specific effects does the multi-point welding process of Heavy Duty Hose Clamp have on their overall durability?

2025.05.30

2025.05.30

Industry News

Industry News

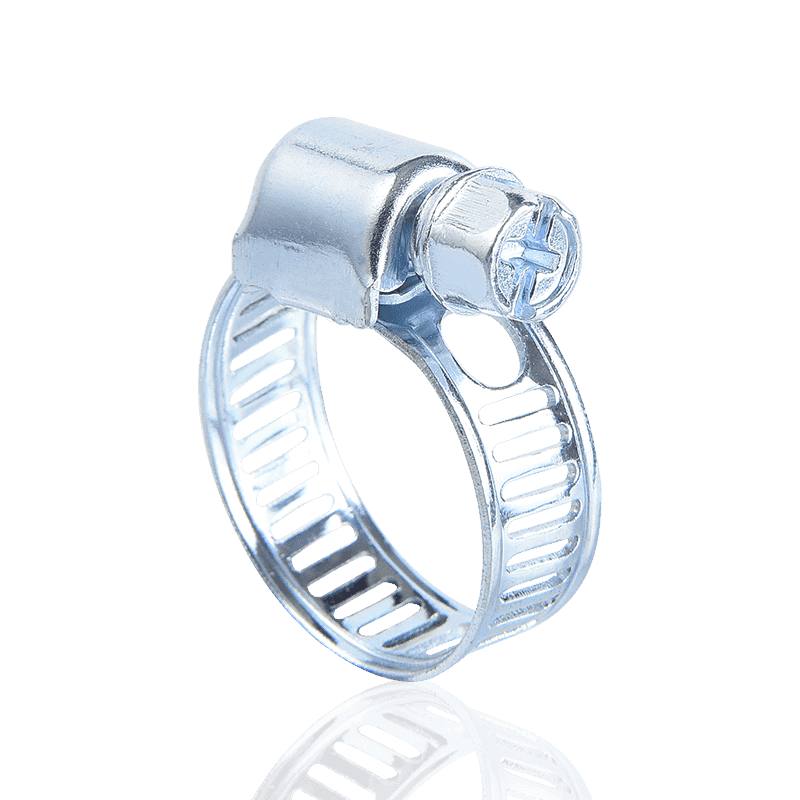

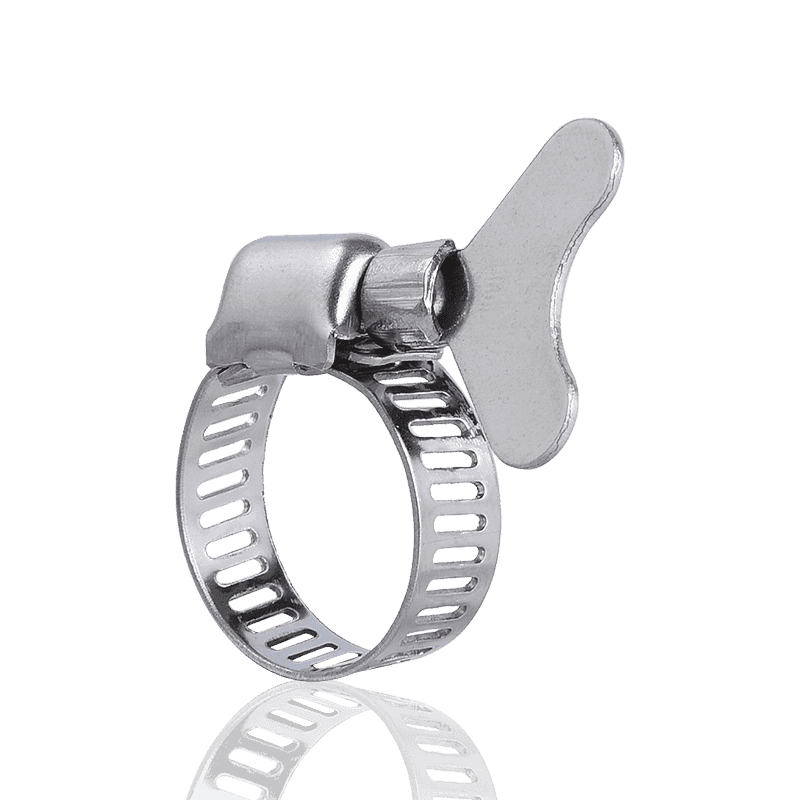

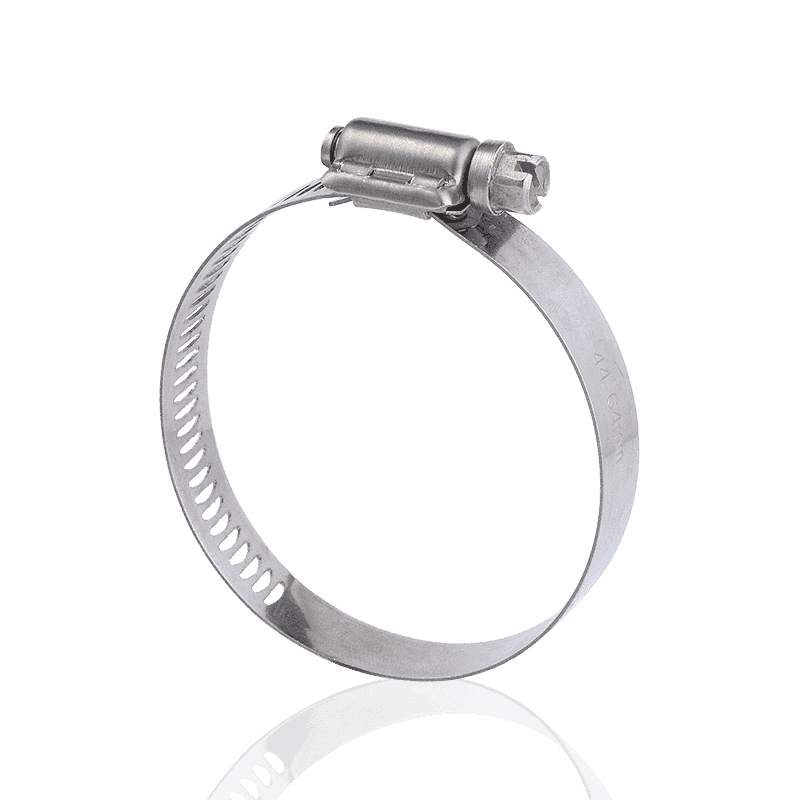

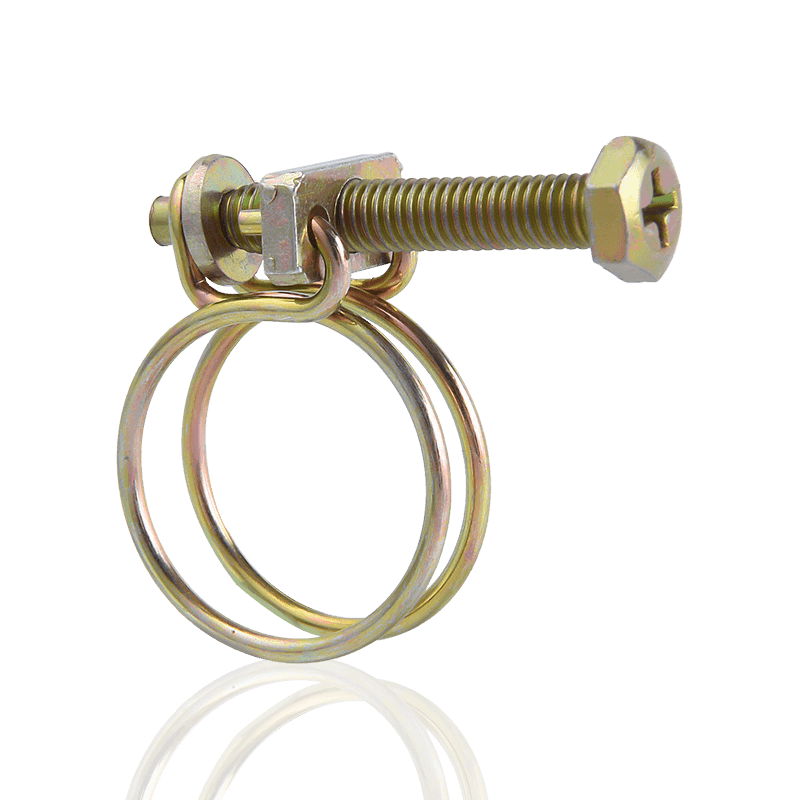

The multi-point welding process forms multiple welding points by welding at multiple key positions of the steel strip. These welding points work together to significantly enhance the overall structural strength of the heavy-duty hose clamp. Compared with single-point welding or simple fixing methods, multi-point welding can more effectively disperse stress and prevent the hose clamp from deforming or breaking when subjected to high pressure or vibration, thereby improving its durability.

The tight connection of the welding points can ensure the sealing between the hose clamp and the pipe or hose. The multi-point welding process further improves the fit and sealing effect of the sealing surface by increasing the number of welding points. Good sealing performance can prevent fluid leakage, protect equipment and environmental safety, and also reduce the maintenance and replacement costs caused by leakage, indirectly improving the durability and service life of the hose clamp.

The multi-point welding process makes the hose clamp more stable and reliable when subjected to various working conditions. The firm connection of the welding points can resist the influence of adverse factors such as vibration, impact and corrosion, and reduce damage and failure caused by these factors. Therefore, Heavy Duty Hose Clamp using multi-point welding technology usually have a longer service life and can operate stably for a long time in harsh industrial environments.

Although aesthetics is not a direct indicator of durability, the multi-point welding process can usually make the welding points more uniform and neat, thereby improving the overall appearance quality of the heavy hose clamp. The beautiful appearance not only meets the aesthetic needs of modern industrial products, but also reflects the manufacturing process and quality level of the product to a certain extent, and indirectly reflects the durability and reliability of the product.

In complex and changing industrial environments, such as extreme conditions such as high temperature, high pressure, and strong corrosion, the multi-point welding process can ensure that the heavy hose clamp maintains structural stability in various harsh environments. The uniform distribution of welding points can reduce the risk of cracking due to local stress concentration, ensuring that the hose clamp is still reliable under extreme working conditions.