Can hose clamps stop leaks?

2025.10.17

2025.10.17

Industry News

Industry News

In industry, automotive, plumbing, and even daily household maintenance, we often face leaks at pipe joints. This is where a seemingly simple yet crucial fastener comes into play: the hose clamp.

Why are hose clamps so effective at stopping leaks?

The primary function of a hose clamp (also commonly known as a hose clamp or pipe clamp) is to tightly and evenly clamp the hose and its fitting, creating a secure, seamless seal at the joint. Its leak-stopping ability is primarily due to several key factors:

Uniform radial pressure:

When a hose clamp is tightened using a screw or worm gear mechanism, it applies uniform radial pressure to the hose. This pressure compresses the hose material against the fitting or nozzle, filling any tiny gaps and creating an air- and liquid-tight seal.

Material and Design:

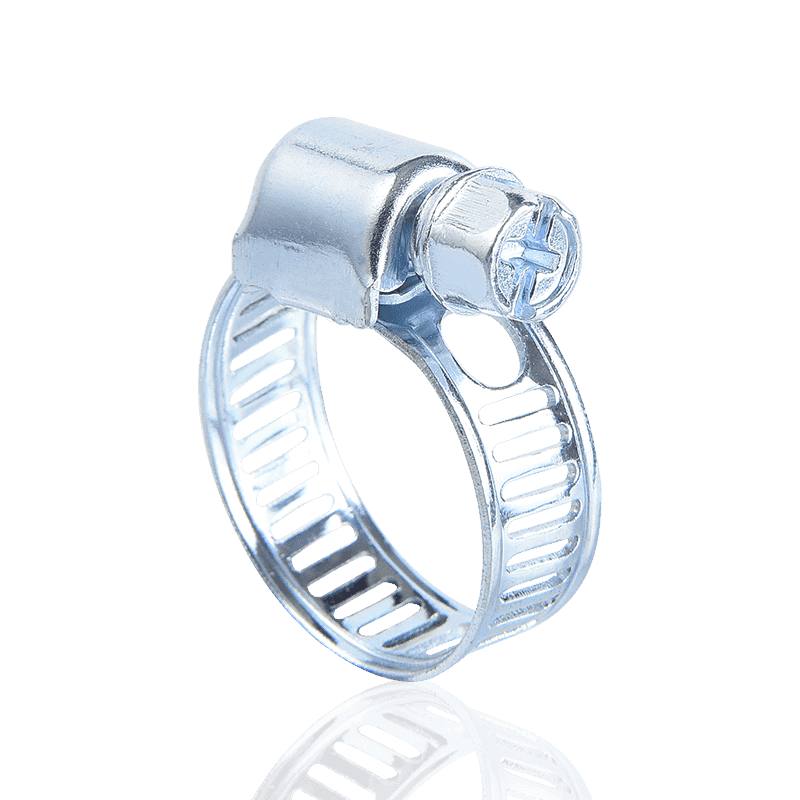

High-quality hose clamps are typically made of stainless steel or carbon steel, offering sufficient strength and corrosion resistance. (This is similar to the material requirements we apply to products like oil plugs and two-way ball valves, which emphasize durability.) Different designs, such as the common American hose clamp (whose through-hole stamping process and torque-balancing features provide a stronger tightening force, making it widely used in automotive pipes, water pumps, and other applications, and has excellent tensile strength) or the German hose clamp, are all designed to provide maximum tightening torque and reliable sealing.

Adaptability:

Whether the hose is subjected to water, oil, chemicals (such as in two-way ball valve applications), or gas, a hose clamp of the appropriate size and material will maintain sealing performance under various pressures and temperatures (just like our PEEK tubing performs in high and low temperature environments).

Hose Clamp Types and Applications

There are many types of hose clamps on the market to suit different application needs, such as:

| Type | Key Features | Typical Applications |

| American style hose clamp | Through-hole design provides strong locking force and balanced torque. | Automotive piping, water pumps, fans, and food processing equipment. |

| German style hose clamp | Side-hole or stamped design with smooth steel band edges protects the hose. | Applications requiring high sealing and hose protection. |

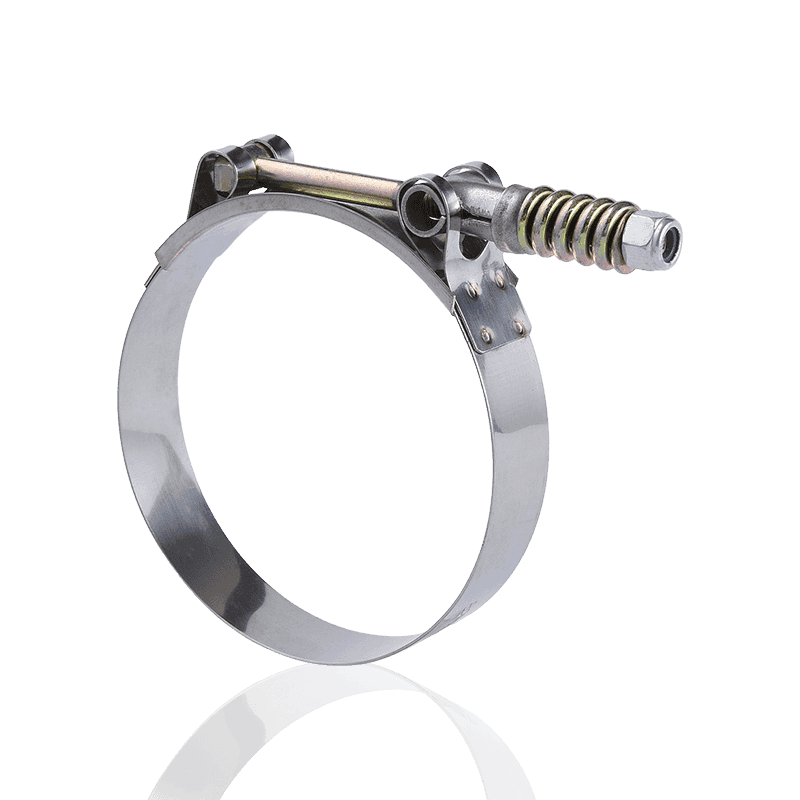

| T-bolt hose clamp | Withstands higher pressures and provides stronger clamping force. | Heavy machinery and industrial high-pressure piping. |

From simple garden hoses to complex hydraulic systems (such as cylinders and pumps, which are exactly where our oil plugs are used), hose clamps are critical fasteners that ensure the safe and efficient operation of fluid transfer systems. Their role goes beyond just "connecting"; it also ensures a secure seal.

How can I correctly select and install hose clamps for optimal leak prevention?

To achieve optimal leak-stopping performance with hose clamps, the following principles must be followed:

Choose the correct size:

The diameter of the hose clamp must match the outer diameter of the hose and the size of the fitting. Oversized or undersized hose clamps will not provide uniform and effective pressure.

Appropriate torque:

When tightening the clamps, apply enough torque to ensure a seal, but not so much that it damages the hose material or breaks the clamp (especially with designs that prioritize bite force, such as Schrader hose clamps).

Check the seal point:

Ensure the hose clamp is seated on the fitting port, completely covering the sealing area.

Hose clamps are essential fasteners for resolving hose leaks. Properly selected and installed, high-quality hose clamps effectively prevent liquid or gas leaks, ensuring system operation and safety. They are the preferred solution for engineers and maintenance personnel in any fluid system requiring a reliable seal.