How to tighten a hose clamp?

2025.10.10

2025.10.10

Industry News

Industry News

Hose clamps are crucial fasteners, widely used to connect hoses and pipe fittings to prevent leaks, particularly in automotive piping, water pumps, fans, and hydraulic systems. Properly tightening hose clamps is crucial for system reliability and safety.

Understanding Your Hose Clamp Type

Before you begin tightening, you must first determine which type of hose clamp you are using. Common types available on the market include:

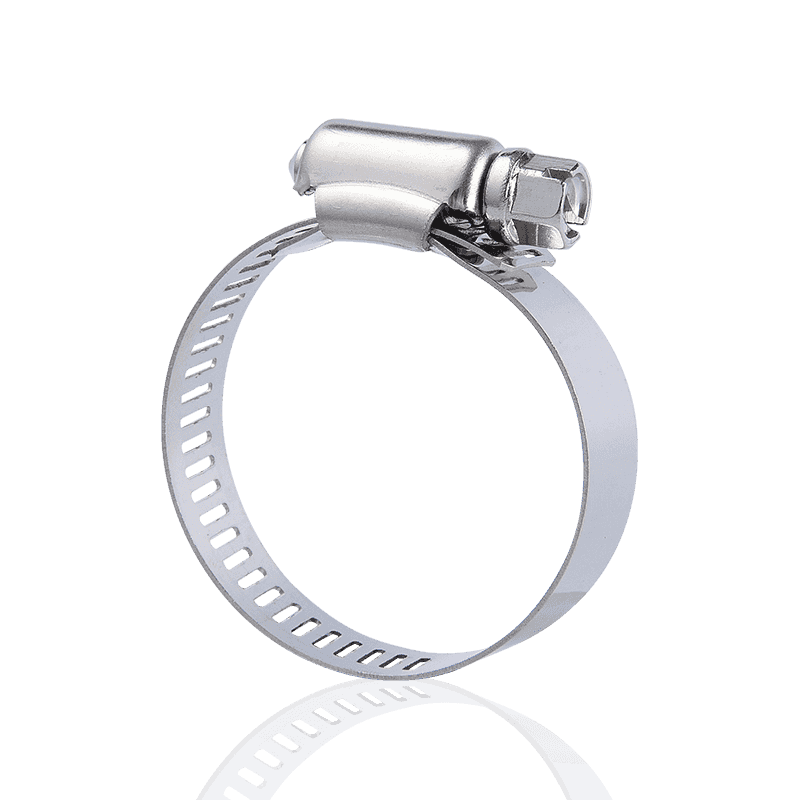

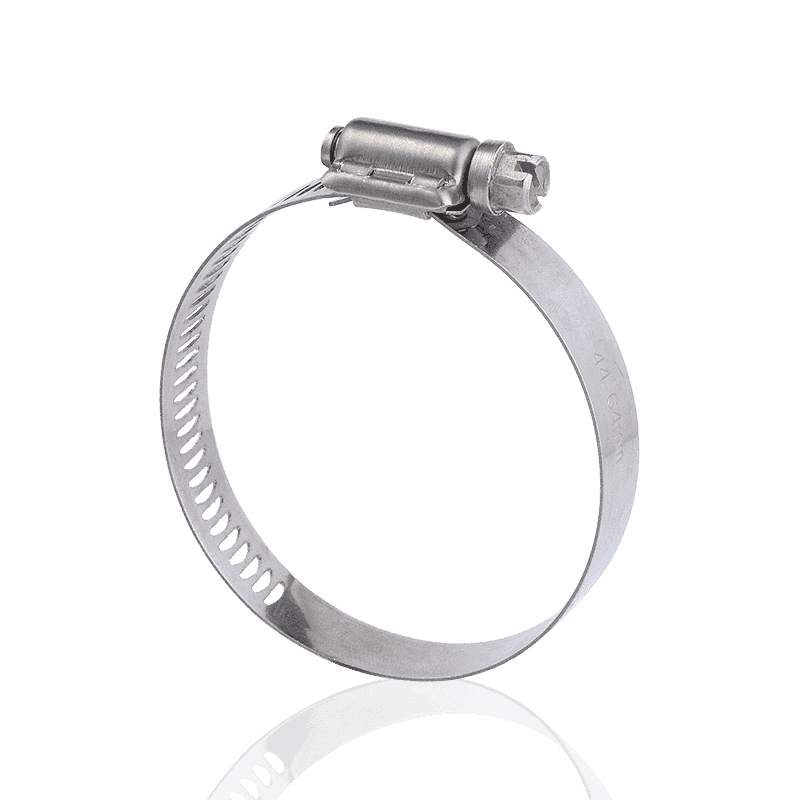

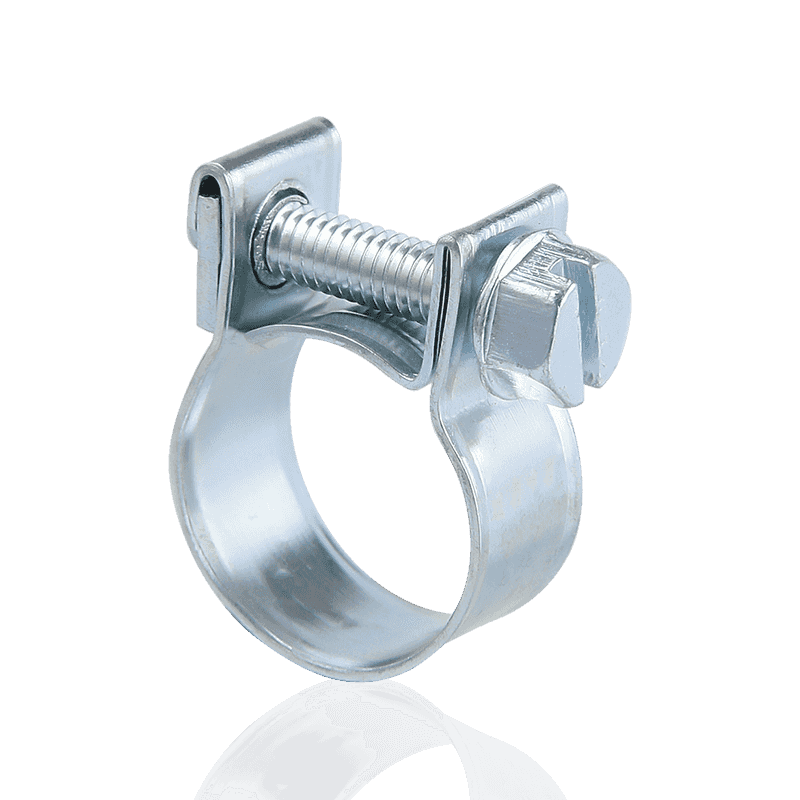

- Worm-drive hose clamps (such as American and German styles):

- American hose clamps (such as the ones we offer, which use a through-hole process) are characterized by their torsion and pressure resistance, balanced torque, and secure locking. They tighten using a metal screw that drives the teeth on a metal band.

- German hose clamps typically have higher tensile strength and are manufactured with more precision.

- American hose clamps (such as the ones we offer, which use a through-hole process) are characterized by their torsion and pressure resistance, balanced torque, and secure locking. They tighten using a metal screw that drives the teeth on a metal band.

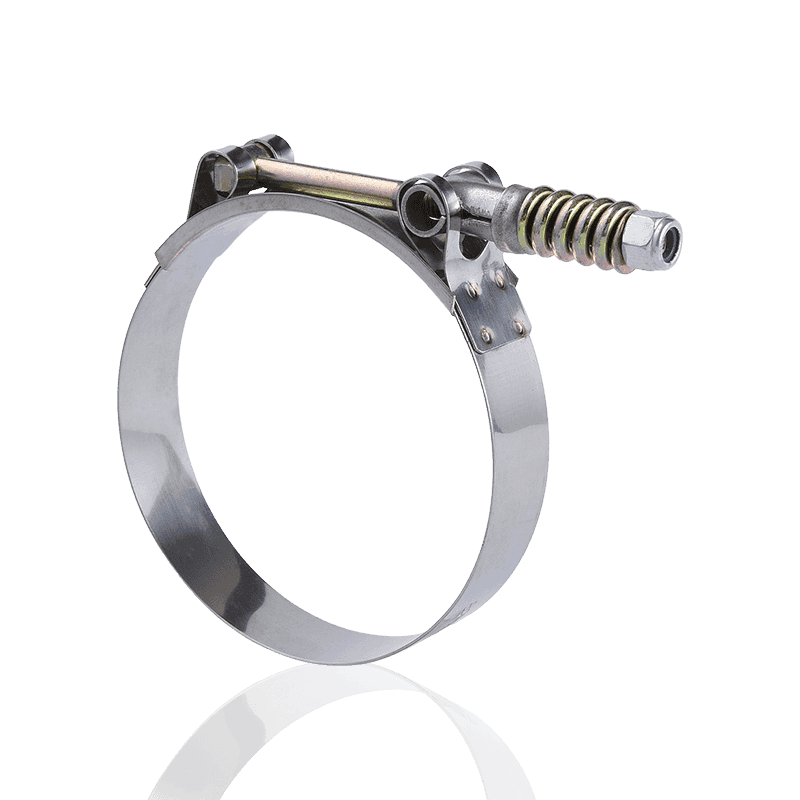

- Spring-loaded pipe clamps: These typically have a preset clamping force and are used in environments with large temperature fluctuations, eliminating the need for manual tightening.

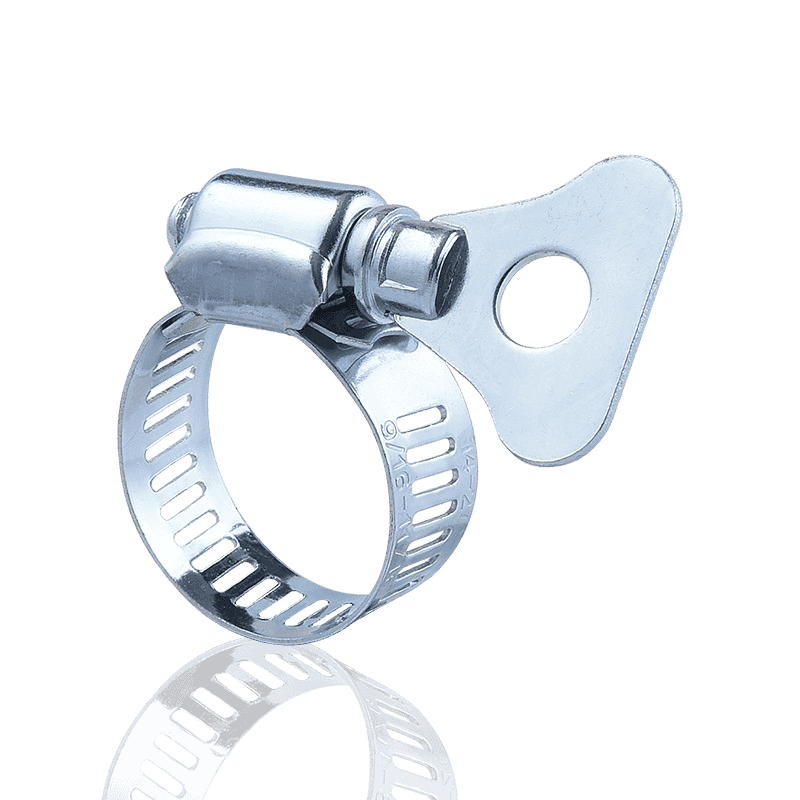

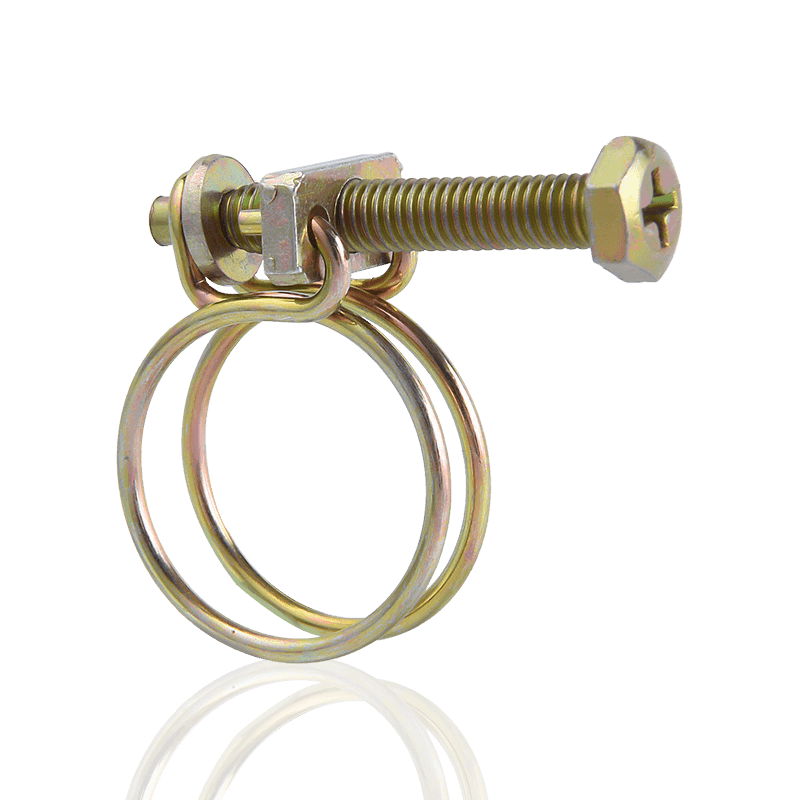

- Wire clamps: These consist primarily of two steel wires and are tightened using a nut or special tool.

For worm-drive hose clamps that require manual tightening, knowing the correct procedure is key.

Steps for Properly Installing and Tightening Hose Clamps

Proper installation position and appropriate torque are two key elements to ensure optimal performance of hose clamps.

1. Positioning the Hose Clamp

Fully insert the hose onto the fitting, ensuring it is in the correct working position. Then, position the hose clamp over the hose, over the portion of the hose that completely covers the fitting. The ideal position is approximately 6 mm (1/4 inch) from the end of the hose, avoiding any ribs or bevels on the end of the hose to ensure the clamping force is applied to the effective area of the fitting.

2. Initial Tightening

Use an appropriate tool (usually a screwdriver or socket wrench) to perform the initial tightening of the metal screw. Tighten the hose clamp only enough to hold it in place and allow adjustment by hand or with a tool.

3. Applying the Correct Torque

This is the most critical step. The torque required to tighten the hose clamp must be just right:

Too loose: This may cause leaks, especially in high-pressure or vibrating environments.

Overtightening: Can damage the hose, shear the hose material, or break the metal band or screw (for example, the steel band of an American style hose clamp can break under strong tension due to the hollow stamping process).

Recommended Action:

- Consult the hose clamp manufacturer (or for products like our American style hose clamps) for recommended torque values. Torque values vary depending on the hose clamp material (such as stainless steel or carbon steel), size, and hose material.

- Use a torque wrench for precise tightening. For most standard hose clamps, the recommended torque is typically between 2.5 N·m and 5 N·m.

- If a torque wrench is not available, tighten evenly and gradually until the hose clamp no longer turns easily but without noticeable deformation or bulging of the hose material. The goal is a secure, evenly torqued clamp.

4. Final Inspection and Retightening

After a period of system operation (for example, after temperature cycling or pressurization), the hose clamp may loosen slightly due to deformation or compression of the hose material. It's recommended to check and retighten after the initial operation to ensure long-term leak-free performance.

Key Tips and Considerations

- Tool Selection: Using the correct tools is crucial. For worm-drive hose clamps, a socket wrench or flat-blade screwdriver is typically required.

- Material Compatibility: In corrosion-resistant applications such as chemical processing or water treatment, hose clamps made of stainless steel should be selected for durability.

- Avoid cross-threading: During tightening, ensure proper engagement between the screw and the metal band to avoid cross-threading.

Proper selection, installation, and tightening of hose clamps are essential for the reliable operation of your industrial processes, vehicles, or machinery. If you're looking for aesthetically pleasing, torsion-resistant, and pressure-resistant hose connectors, our American-style hose clamps are a superior choice.