How to Choose the Right Hose Clamp?

2025.10.24

2025.10.24

Industry News

Industry News

In industrial production, automotive maintenance, water treatment, and even everyday household repairs, hose clamps (also often called hose clamps or pipe clamps) are critical fasteners for securing pipe connections and ensuring reliable seals. Proper hose clamp selection and use not only prevents leaks and ensures efficient system operation, but also significantly extends the lifespan of equipment and piping.

1. Identify the Application and Media

First, you need to determine the environment in which the hose clamp will be used and the type of hose it will clamp.

- Media Type (Liquid/Gas/Chemical): If the media is corrosive (such as chemicals or salt water), a corrosion-resistant material is essential.

- Temperature and Pressure: High-temperature or high-pressure applications require stronger hose clamps with improved sealing to prevent loosening due to thermal expansion and contraction or pressure shock.

- Vibration Environment: For machinery subject to high vibration, consider using hose clamps with enhanced locking mechanisms, such as models with gaskets or self-locking designs.

2. Consider the Hose Clamp's Material and Corrosion Resistance

The material of a hose clamp directly determines its durability and suitability. Common materials include:

| Material | Advantages | Typical Applications |

| Carbon Steel | Low cost, moderate strength | Dry, low-corrosive environments |

| Stainless Steel | Excellent corrosion resistance, high strength (such as 304 and 316) | Automotive, marine, chemical, food processing, water treatment |

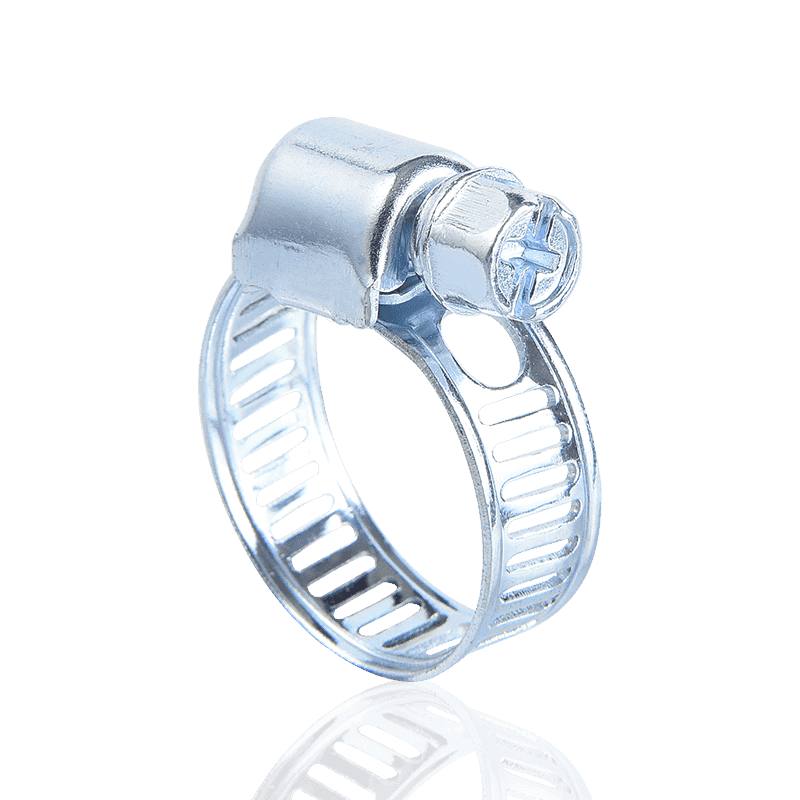

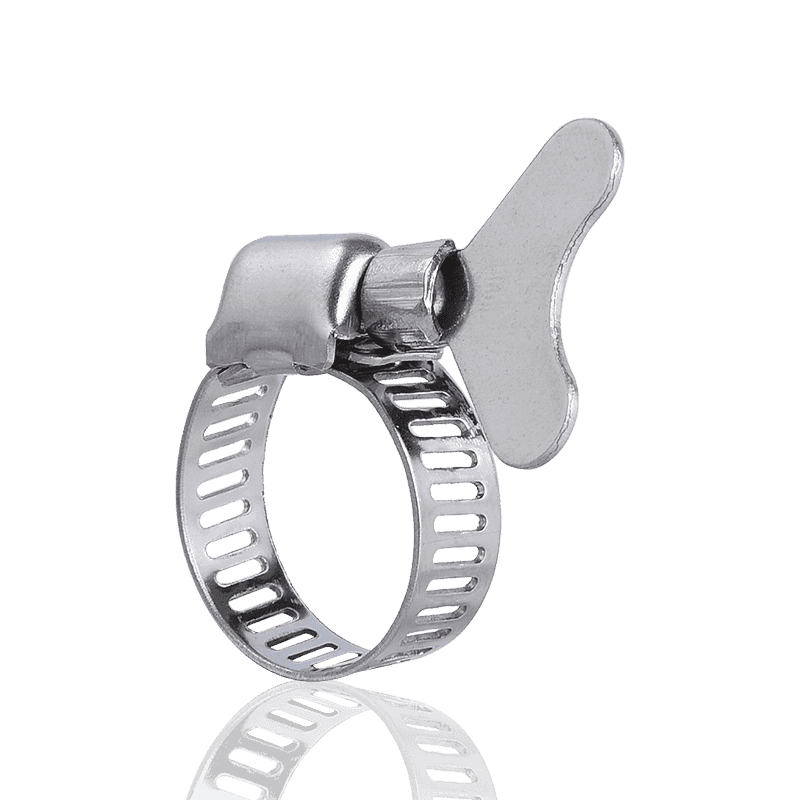

Our American-style hose clamps are made of stainless steel or carbon steel and are widely used for connecting hoses in automotive piping, water pumps, fans, and other equipment. They offer torsion resistance, pressure resistance, and a secure lock. When selecting a hose clamp, pay particular attention to whether the screws and band rings are made of materials compatible with the environment.

3. Understanding Hose Clamp Types and Structures

Different hose clamp structures are suitable for different needs, so it is important to understand their characteristics:

- American-style hose clamp (through-hole): Utilizing a through-hole process, this clamp offers balanced torsional torque and a wide adjustment range. While the steel band may not withstand strong tension as German-style clamps, it offers greater torsional resistance than German-style clamps. Suitable for connections requiring aesthetically pleasing aesthetics.

- German-style hose clamp (stamped): Offers higher edge strength and more uniform radial pressure, and is typically used for demanding or high-pressure seals.

- Heavy-duty hose clamp: Designed for large-diameter, thick-walled hoses or those subject to high pressure, it provides stronger clamping force.

- Spring-loaded hose clamps: These automatically adjust the clamping force with temperature changes, making them suitable for applications subject to large temperature fluctuations, such as automotive cooling systems.

When selecting a hose clamp, the adjustment range of the hose clamp should be determined based on the hose diameter, ensuring that the hose diameter falls within the clamp's effective range for optimal clamping.

4. Focus on Performance Parameters

When choosing a hose clamp, consider the following key parameters to ensure quality:

- Torque: The maximum tightening torque a hose clamp can withstand. A high-quality hose clamp should provide sufficient radial clamping force at the specified torque without damaging its structure.

- Sealing: Especially for fluid lines, advanced sealing designs ensure leak-proof connections.

- Shock/Vibration Resistance: A good design can withstand the vibration and shock generated during system operation.

Selecting the right hose clamp requires a comprehensive consideration of the application environment, media characteristics, material corrosion resistance, and product structural performance. Only by choosing the most suitable hose clamp can you ensure the safe, reliable, and long-term operation of your piping system.