How to Correctly Measure and Determine the Required Hose Clamp Size?

2025.12.12

2025.12.12

Industry News

Industry News

In industrial, automotive, agricultural, and even everyday household applications, hose clamp (also known as hose reels or clamps) are core components ensuring the sealed, safe, and reliable operation of fluid or gas transmission systems. However, many leaks and failures often stem from improper hose clamp size selection.

- 1 Why is accurate measurement crucial?

- 2 Correct Measurement Steps for Hose Clamp Size: To determine the required hose clamp size, you need to measure the outer diameter (O.D.) of the "installed hose." Please note that the object being measured is the hose fitted onto the fitting or pipe.

- 3 Advanced Selection: Considering the Application Environment and Hose Clamp Type

Why is accurate measurement crucial?

The core principle for selecting hose clamp size is to ensure the required diameter is within the clamp's minimum and maximum clamping range, ideally in the middle of that range.

Too small: The clamp cannot be fitted or tightened, leading to installation failure.

Too large: Even when tightened to its limit, the clamp cannot provide sufficient radial pressure, resulting in a poor seal, system pressure leaks, or hose detachment.

Excessively tight or loose: Even if it can clamp, it affects the torque and clamping force uniformity of the clamp, potentially causing localized hose damage or long-term stress failure.

Correct Measurement Steps for Hose Clamp Size: To determine the required hose clamp size, you need to measure the outer diameter (O.D.) of the "installed hose." Please note that the object being measured is the hose fitted onto the fitting or pipe.

Step 1: Measure the Outer Diameter (O.D.) of the Installed Hose

This is the most crucial step.

Tools Needed: Use a high-precision vernier caliper or measuring tape (for large-diameter hoses).

Installing the Hose: Fully insert the hose (e.g., rubber hose, silicone hose) into the barb portion of the fitting, fitting, or pipe to be clamped.

Accurate Measurement: Measure the outer diameter of the hose at the position where it is already fitted onto the fitting and ready for the hose clamp.

Important Note: The hose's outer diameter will expand after being fitted onto the fitting. This expanded diameter is the actual size the hose clamp needs to clamp. Never measure only the outer diameter of the hose in its uninstalled state.

Average Measurement: It is recommended to measure the diameter at two points perpendicular to each other on the circumference and take the average to eliminate slight elliptical distortion.

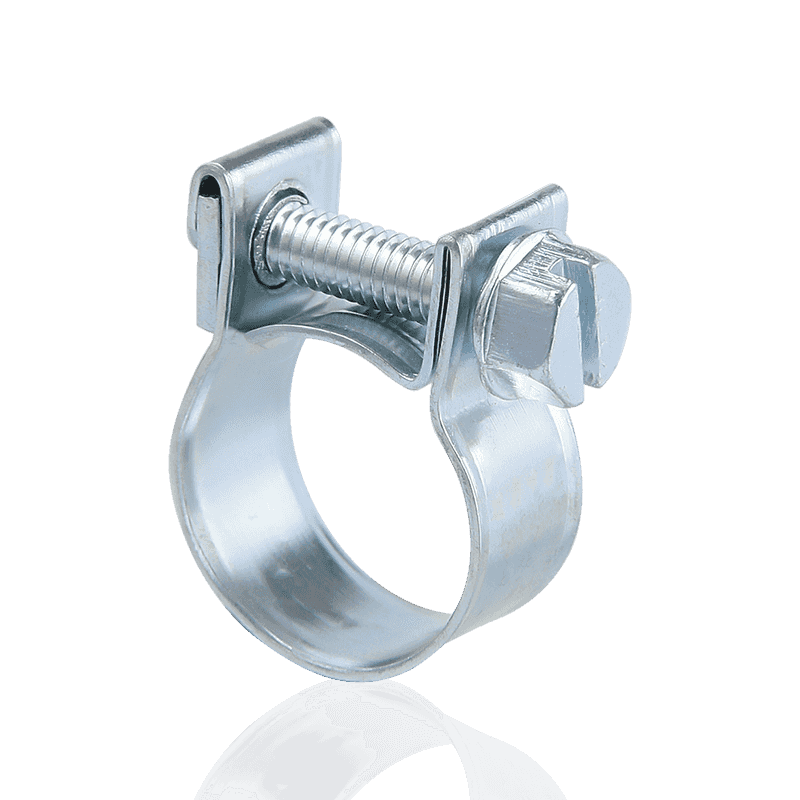

Step Two: Selection and Matching – Matching the Hose Clamping Range

After obtaining the accurate "installed hose outer diameter," the next step is to match the hose clamp specifications.

Identifying the Product Range: Professional hose clamp products will indicate their "minimum clamping diameter" and "maximum clamping diameter."

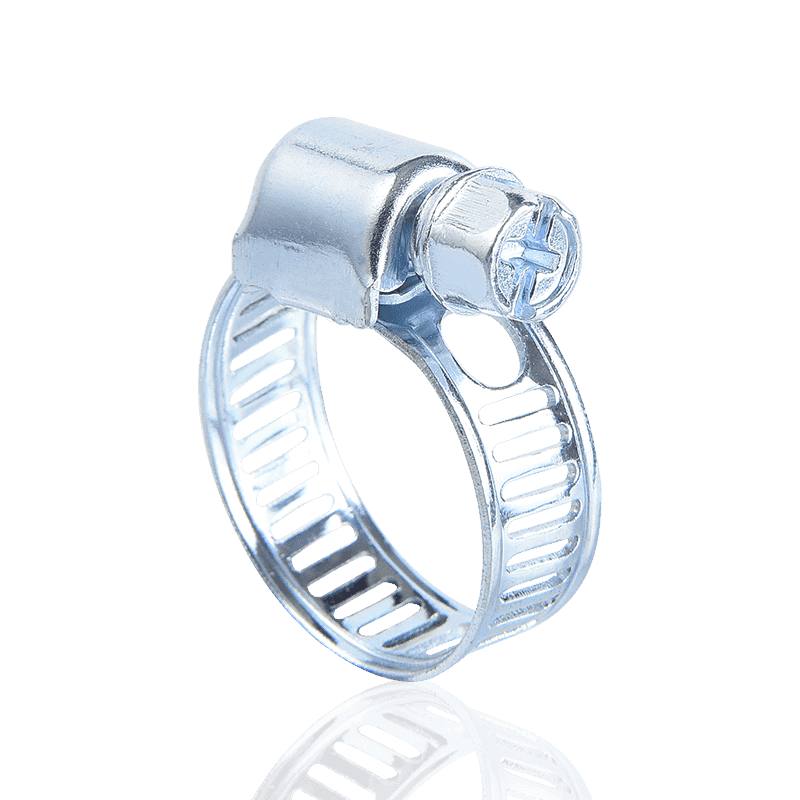

For example: A worm gear hose clamp might have a specification of 20mm - 32mm.

Matching Principle: Ensure that the installed hose outer diameter you measured falls within the middle third of the selected hose clamp specification range.

If the measured diameter is 25mm, a 20mm - 32mm clamp is ideal because it falls in the middle, leaving sufficient adjustment margin.

Advanced Selection: Considering the Application Environment and Hose Clamp Type

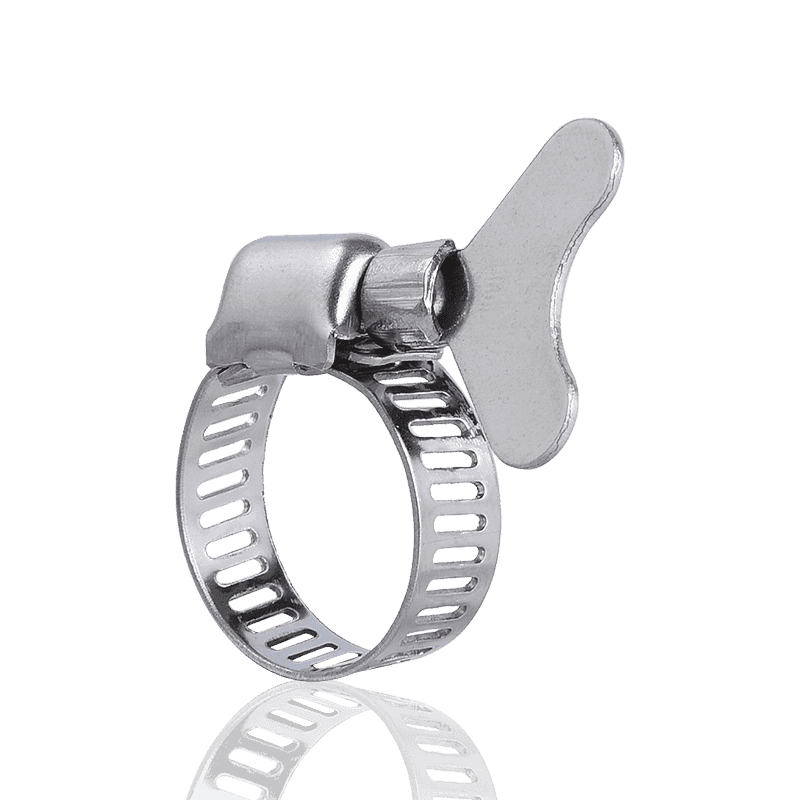

Besides accurate dimensional measurement, correct hose clamp selection also requires considering the specific application environment and performance requirements to determine the most suitable hose clamp type:

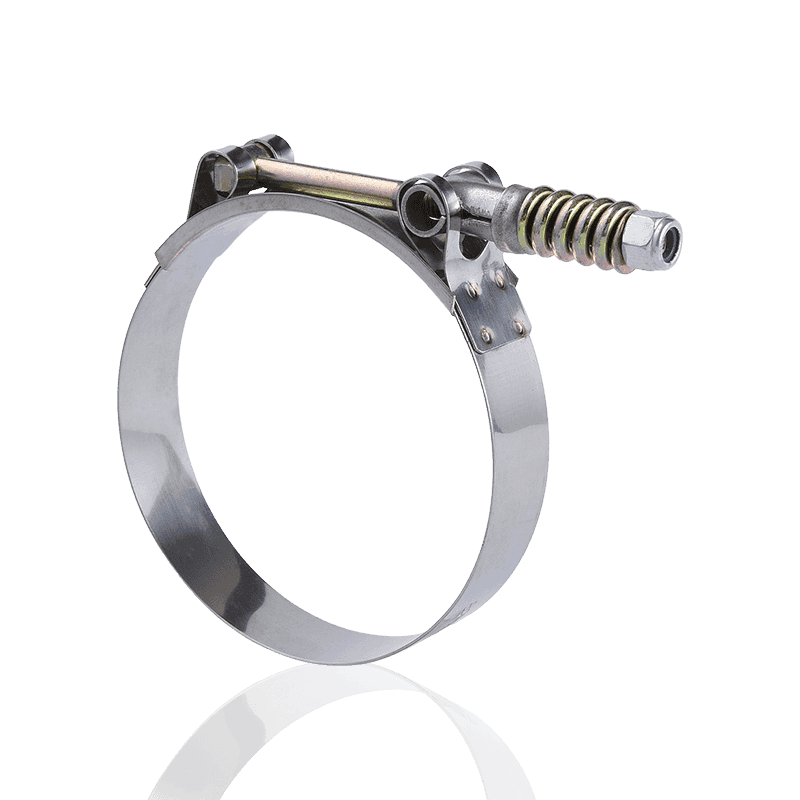

High Pressure or High Vibration Environments:

Description: When the hose connection needs to withstand high internal pressure, or the system experiences frequent mechanical vibration.

Recommended Hose Clamp Type: T-bolt type hose clamps should be selected because they provide higher and more uniform clamping force, ensuring reliable connections.

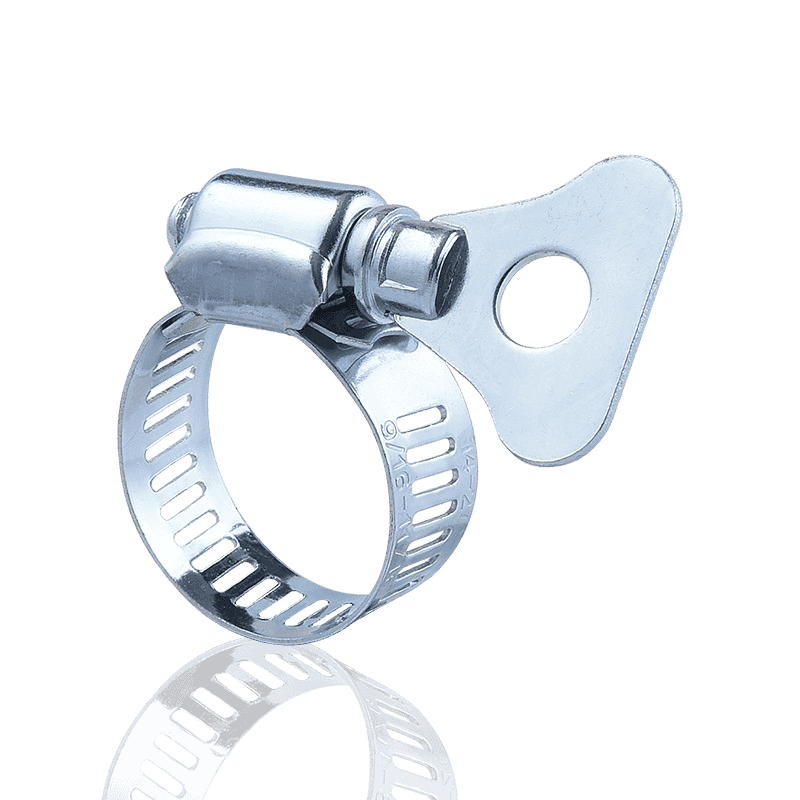

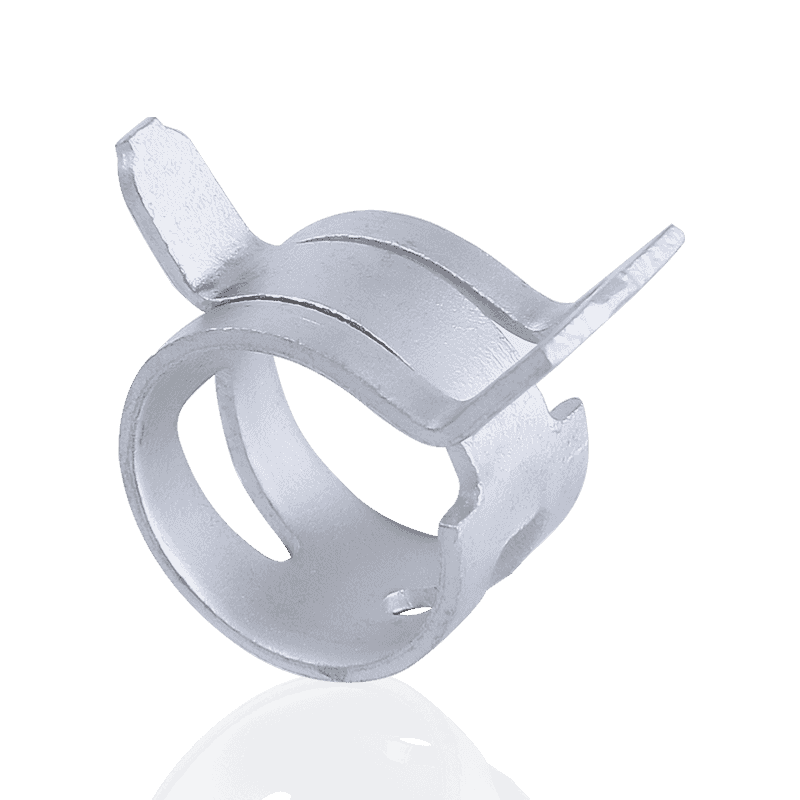

Environments with Drastic Temperature Variations:

Description: Large fluctuations in system operating temperature may cause significant thermal expansion and contraction of the hose, affecting its sealing performance.

Recommended Hose Clamp Type: Constant force hose clamps are recommended. These clamps automatically compensate for diameter changes through a built-in spring mechanism, maintaining a constant clamping force across the entire temperature range and preventing leaks.

Environments Requiring High Corrosion Resistance:

Description: Applicable to corrosive environments such as humid, salt spray, marine environments, or contact with chemical media.

Recommended Hose Clamp Type: 316 stainless steel hose clamps must be used. They provide the highest level of corrosion resistance, ensuring the connection maintains structural integrity and function under harsh conditions.

Correctly selecting the hose clamp size is the cornerstone of ensuring your fluid system operates leak-proof and safely. If you have any questions about hose clamp specifications or require customized solutions, please feel free to contact our professional hose clamp technical team.