What are hose clamps used for?

2025.12.19

2025.12.19

Industry News

Industry News

In industrial production, automotive repair, and even everyday home maintenance, we often see a small, unassuming part – the hose clamp. Although small in size, it plays a crucial role in ensuring the sealing and safety of a system.

What is a hose clamp?

A hose clamp, also known as a hose clip or hose clamp, is a fastener used to secure hoses to fittings (such as pagoda fittings or metal pipe fittings). Its core function is to apply physical pressure to ensure the inner wall of the hose fits tightly against the outer diameter of the fitting, thus preventing liquid or gas leakage and ensuring the hose does not detach under pressure fluctuations or vibration.

Main uses of hose clamps:

1. Achieving a perfect seal

This is the most basic and important function of a hose clamp. Leaks are most likely to occur at fittings when conveying water, oil, air, or chemical media. By using high-quality Hose clamps, pressure can be applied evenly to the circumference of the hose, filling tiny gaps and ensuring the system remains tight even under high pressure or vacuum.

2. Preventing Hose Disconnection

In dynamically operating equipment, pressure surges and mechanical vibrations from the fluid can often cause hoses to detach from their joints. Hose clamps provide strong mechanical locking force, firmly securing the hose even under sudden pressure increases, preventing equipment downtime or safety accidents caused by hose disconnection.

3. Extending Piping System Lifespan

Without hose clamps, hoses are prone to friction and wobbling at the joints, accelerating material aging and wear. Proper tightening not only protects the joints but also optimizes fluid flow and reduces system internal losses.

Common Types of Hose Clamps and Their Applications

To meet different pressure requirements and installation environments, Hose clamps have evolved into various designs. Below is a detailed introduction to several mainstream types and their core uses:

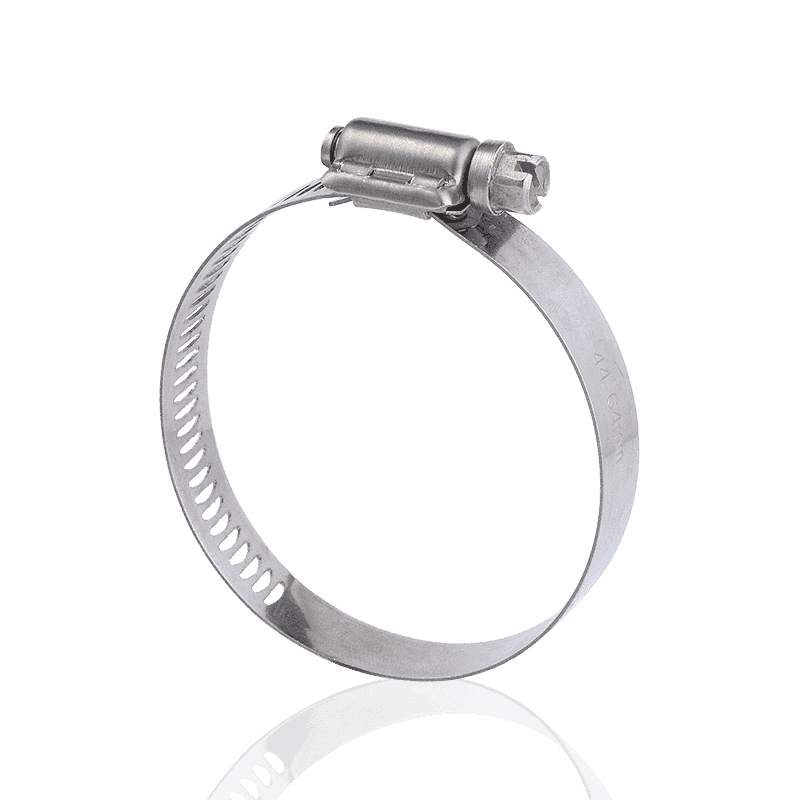

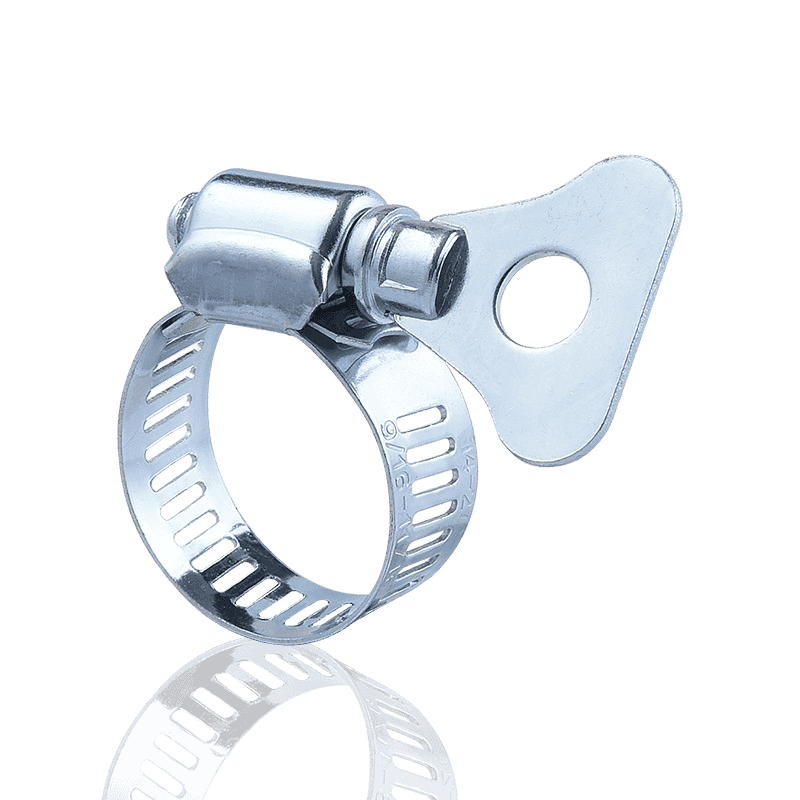

Worm Gear Hose Clamps

This is the most widely used type of hose clamp, characterized by its very wide adjustment range. Adjusting the bolts with a screwdriver or socket wrench allows for easy adaptation to different diameter pipes. It is commonly used in automotive engine compartments, household water pipe repairs, and general industrial piping connections.

T-Bolt Hose Clamps

For high-pressure environments or large industrial equipment, T-clamps are the better choice. These clamps have extremely high tensile strength, providing a stronger and more uniform tightening force than ordinary clamps, making them commonly used in heavy machinery, turbocharging systems, and high-pressure pumping systems.

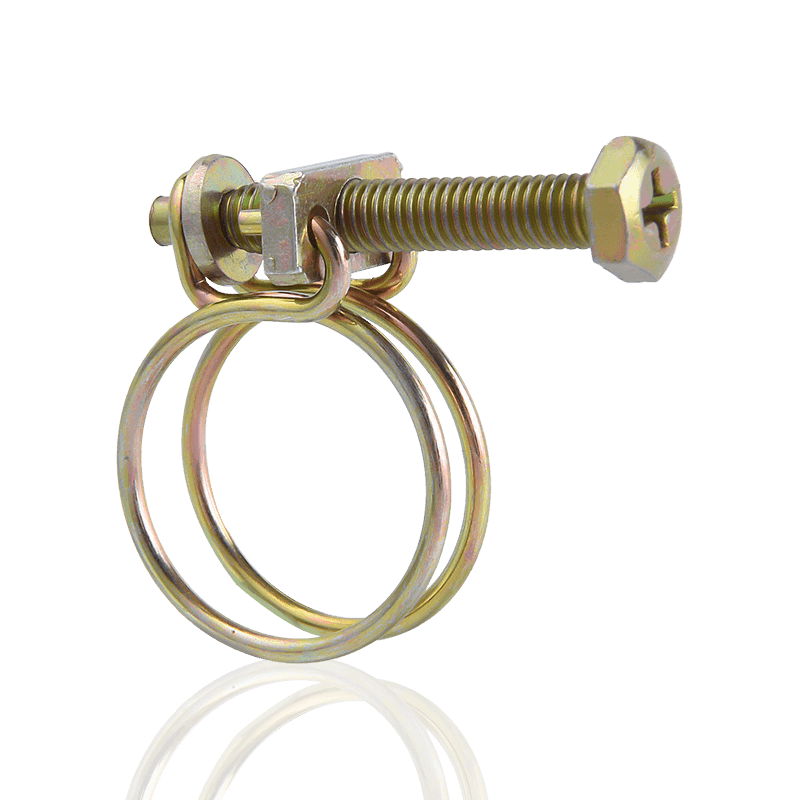

Spring Clamps

Made of spring steel, these clamps have a unique "self-adjusting" function. They automatically adjust tension according to the thermal expansion and contraction of the pipe, maintaining a constant pressure, making them ideal for automotive cooling systems or return lines for liquids with significant temperature variations.

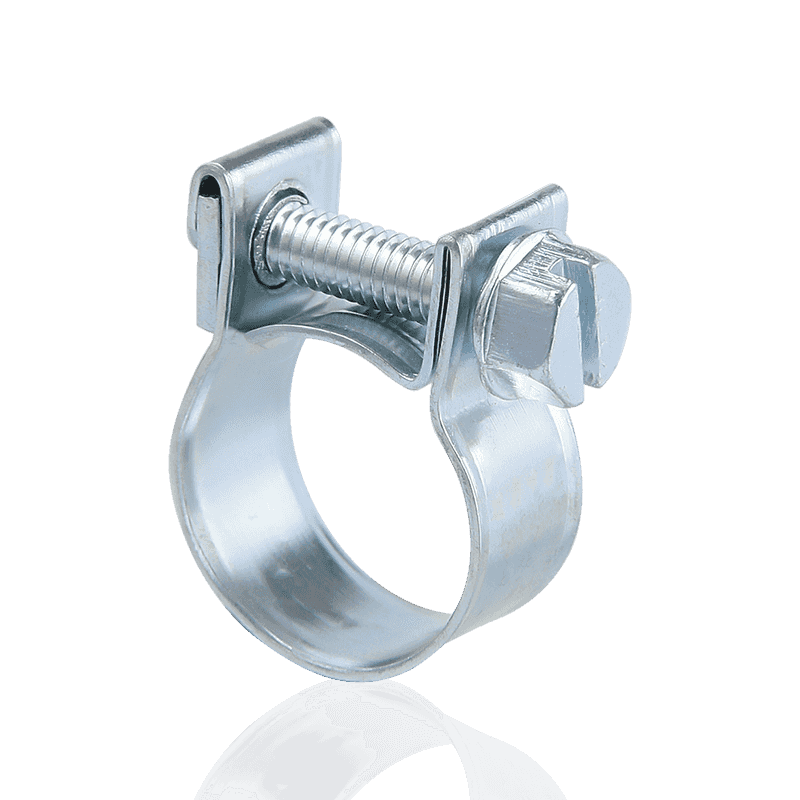

Ear Clamps

These clamps provide a seamless 360° seal after installation. Their compact design and lack of protruding long bolts save space. They are commonly used in industries with high hygiene and space requirements, such as food processing, beverage machinery, and precision medical devices.

Precautions When Purchasing Hose Clamps

To ensure optimal performance of Hose clamps, consider the following points when selecting them:

- Material Selection: For humid or corrosive environments, prioritize 304 or 316 stainless steel to prevent rust.

- Size Matching: Measure the outer diameter of the hose after installation in the fitting to ensure the selected size falls within that range.

- Edge Finishing: High-quality hose clamps typically have flanged edges to prevent scratching the hose surface.

Hose clamps are the "safety guardians" of connection systems. Whether ensuring proper cooling of a car engine or maintaining the smooth operation of a factory production line, a small hose clamp is indispensable. Choosing the appropriate type and material of fastener not only improves work efficiency but also effectively prevents the risk of leaks.