What are quick-release hose clamps? What is their core structure?

2026.01.02

2026.01.02

Industry News

Industry News

In the industrial fastener field, quick-release hose clamps are increasingly becoming the preferred choice for ventilation systems, large-diameter pipeline maintenance, and emergency repairs due to their efficient installation and superior ease of use.

What are quick-release hose clamps?

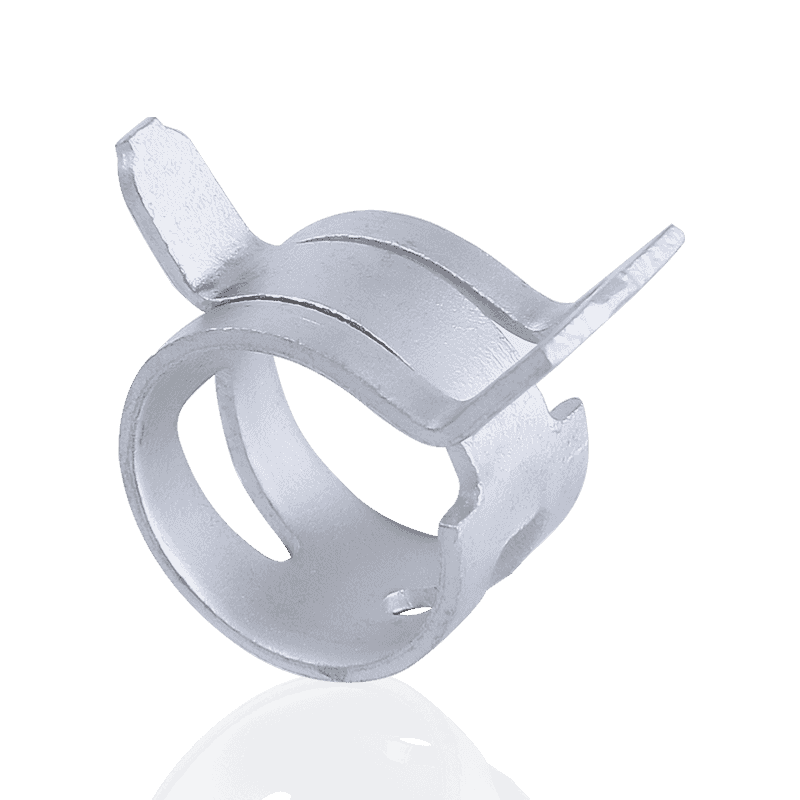

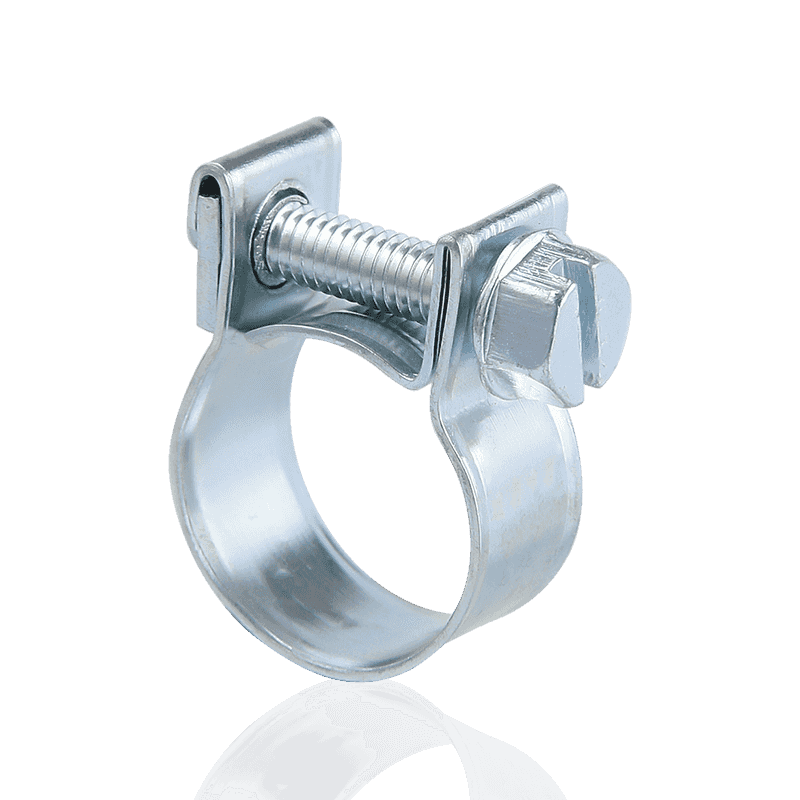

Quick-release hose clamps are special fastening devices designed for applications requiring frequent disassembly or large-diameter piping. Their most significant feature is the use of a swivel-action locking mechanism.

Unlike ordinary hose clamps, which must be inserted along the end of the pipe, the steel strap of a quick-release hose clamp can be fully opened. This means that in some already installed long pipelines or sealed systems that cannot be disconnected, operators can directly bypass the clamp to install it. This "plug-and-play" characteristic makes it excellent in scenarios such as ventilation and dust removal (HVAC), signage fixing, and temporary leak repair.

Detailed Explanation of the Core Structure of Quick-Release Hose Clamps

A high-quality quick-release hose clamp typically consists of four key components, each whose precision directly affects its tightening pressure and corrosion resistance lifespan:

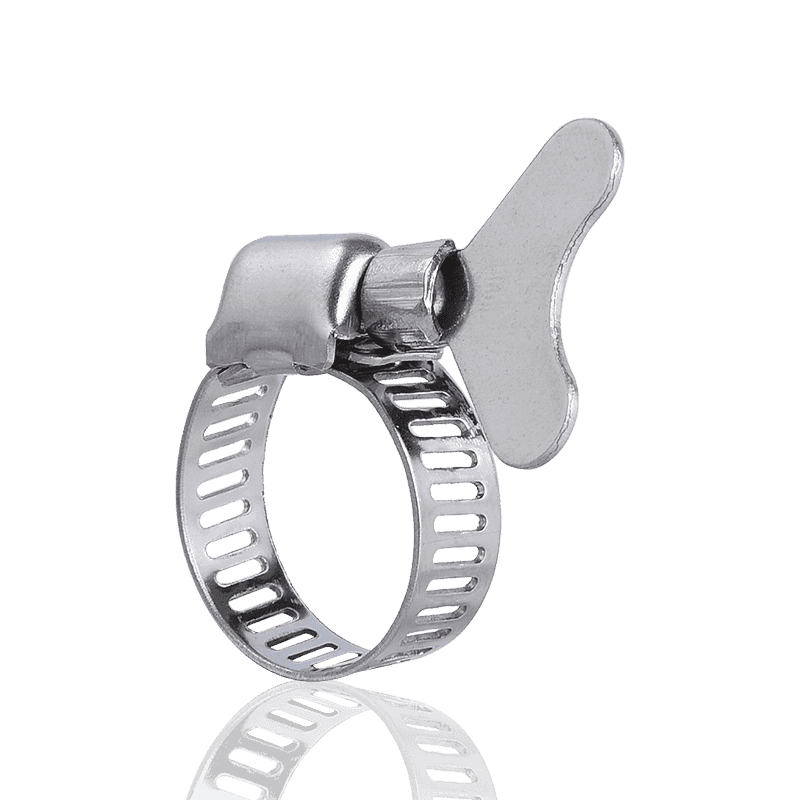

1. Swivel Housing

This is the heart of the "quick-release" function. The housing connects to one end of the steel strip and features a swing-out hinge design.

Function: The user can lift the screw, allowing the steel strip to slide in or out quickly. Once positioned, lowering the screw secures the clamp.

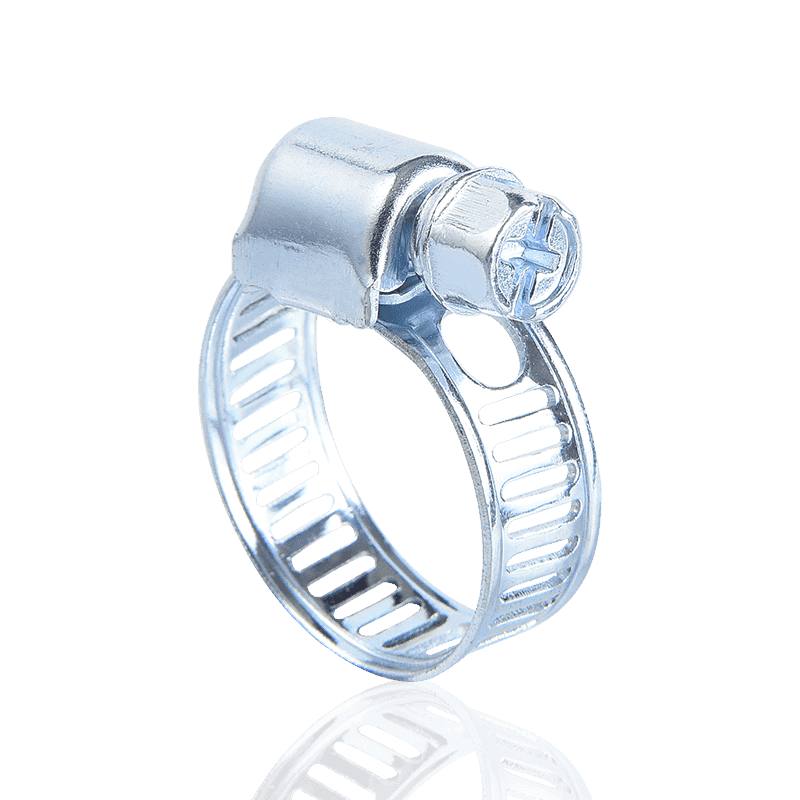

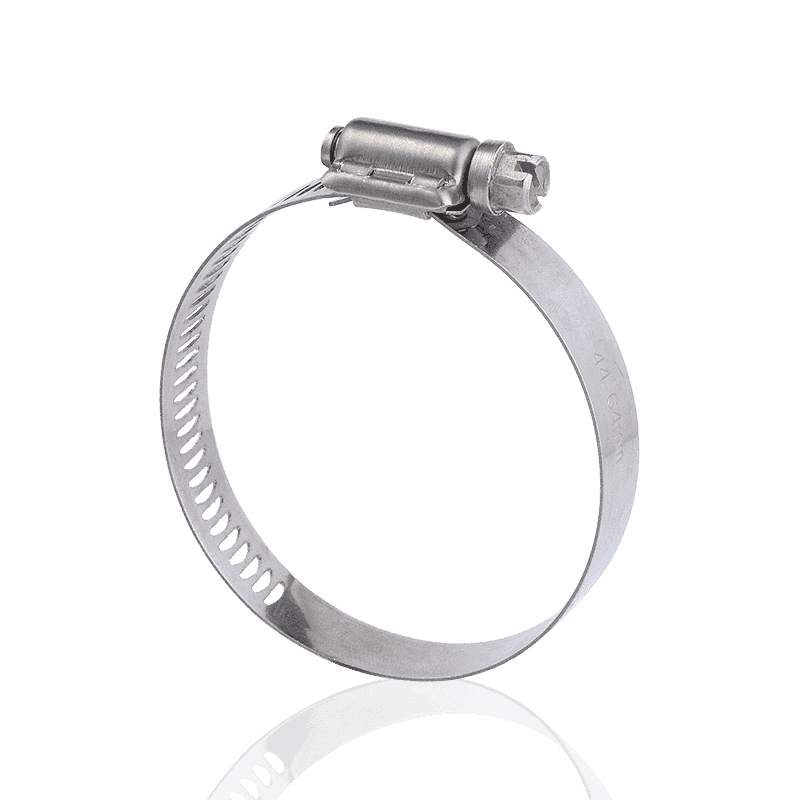

2. Perforated/Stamped Steel Strip

The steel strip is the core component that bears the tensile force. High-quality quick-release hose clamps are typically made of 304 or 316 stainless steel to ensure durability in humid or corrosive environments.

Design: The steel strip surface features precisely spaced rectangular holes or indentations that perfectly mesh with the screw threads.

3. Worm Screw

Although named for quick release, the final tightening force still relies on the screw's rotation.

Details: The screw head is typically designed with a hexagonal head and slotted or Phillips head for easy application of pressure using power tools or a hand screwdriver.

4. Steel Strip Edge Finish

Clamps manufactured by professional companies have their steel strip edges flanged or rounded.

Importance: This design effectively prevents cuts to the hose surface during tightening, protecting the pipe's seal.

Why Choose Our Quick-Release Hose Clamps?

As a stainless steel clamp supplier with years of experience in the industry, our quick-release hose clamps offer the following advantages:

- Fast Installation: Installation time is reduced by approximately 60% or more compared to standard models.

- Wide Size Coverage: We offer customized services from 2 inches to 20 inches and even larger diameters.

- High Torque Performance: Precision thread engagement ensures a tight, secure hold even under strong vibrations.

If you are looking for a pipe fastening solution that can significantly improve engineering efficiency, quick-release hose clamps are undoubtedly your ideal choice.