Why are American-type hose clamps the preferred solution for industrial connections?

2026.01.09

2026.01.09

Industry News

Industry News

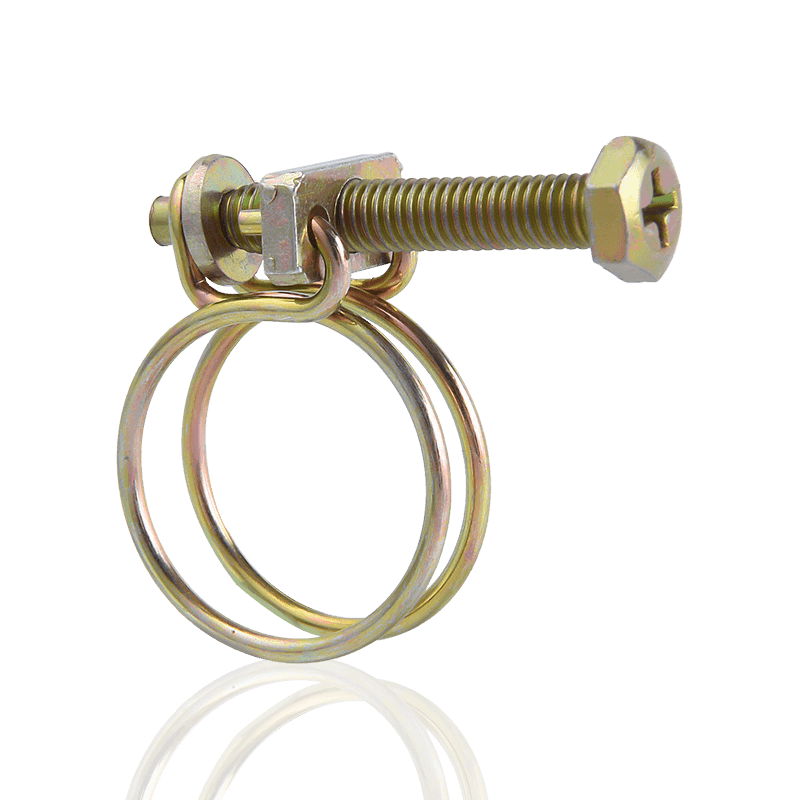

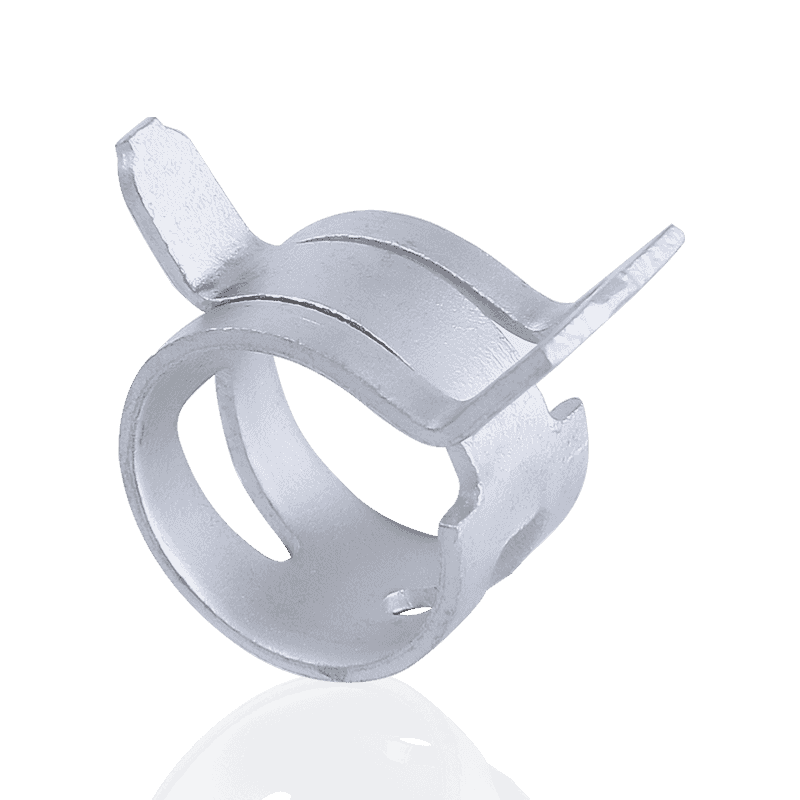

In modern industrial fluid transport and piping systems, a seemingly insignificant component often determines the safety and stability of the entire system—this is the hose clamp. Among numerous standards, American-type hose clamps, with their unique design and superior tightening performance, have become a staple in the global machinery, automotive, and home appliance industries.

What are American-type hose clamps?

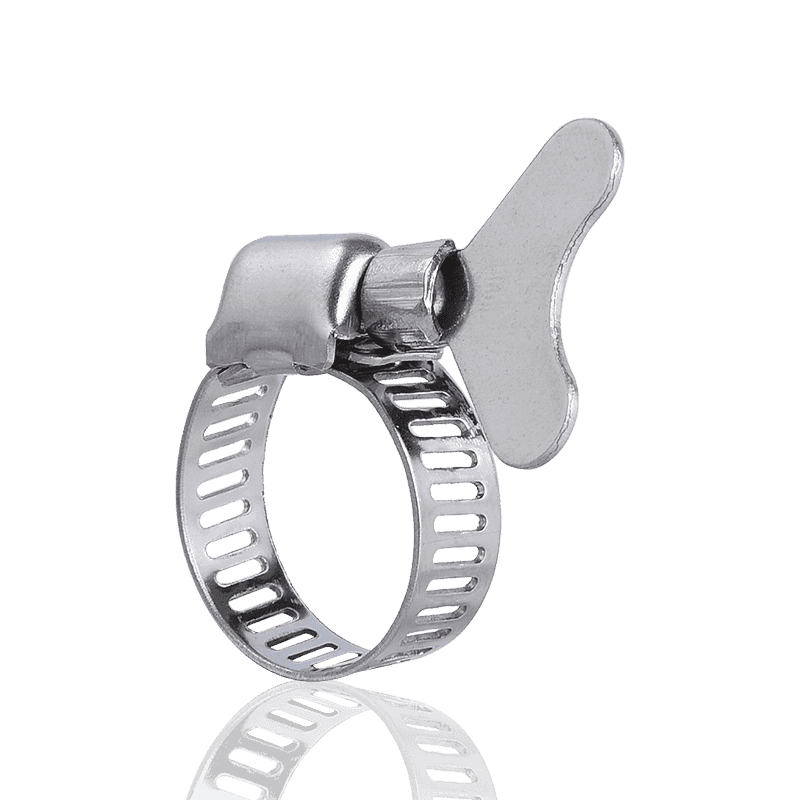

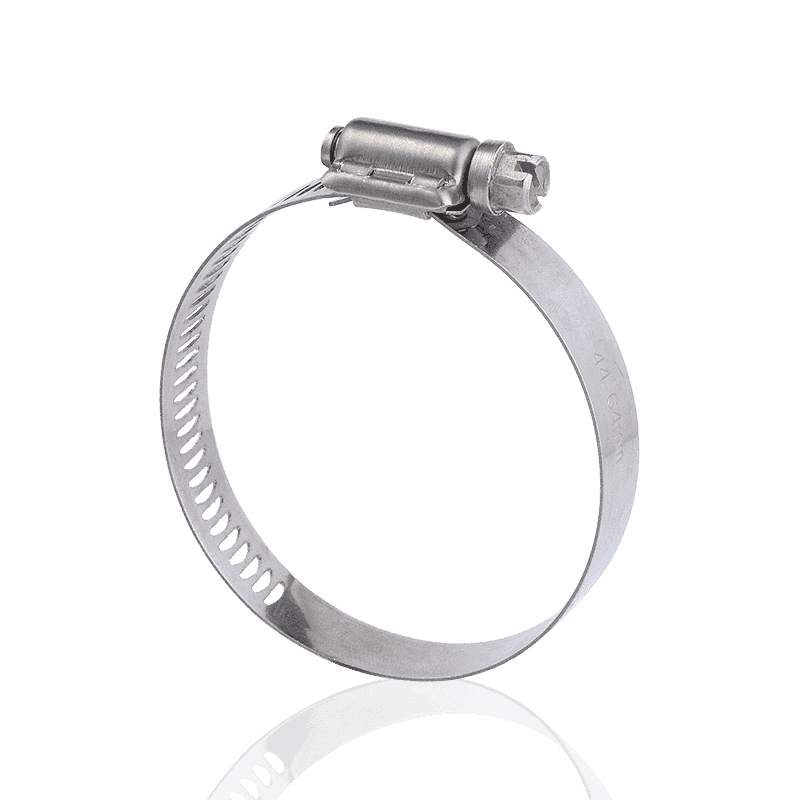

American-type hose clamps, often referred to as American hose clamps, primarily employ a worm gear drive structure. Their most distinctive feature is the through-hole (slotted steel strip) design on the steel strip, which engages with the threaded screw for a secure tightening.

Compared to European or German-type clamps, American-type hose clamps offer a wider tightening range and greater flexibility, adapting to hoses and fittings of various wall thicknesses.

Core Advantages of American-type Hose Clamps

Why do engineers still prefer American-type hose clamps in complex environments? Here are their core competitive advantages:

Superior Material and Corrosion Resistance: High-quality American-type hose clamps are typically made of 304 or 316 stainless steel. This allows it to maintain strong tightening force and resist rust and breakage even in harsh environments such as humidity, acids, alkalis, and salt spray.

High Torque and Uniform Force Distribution: Through a precise worm gear drive design, American-style hose clamps provide uniform circumferential pressure during tightening. This design effectively prevents fluid leakage and can withstand high internal pressure.

Easy Installation and Versatility: Installation can be easily completed using flathead screwdrivers, Phillips screwdrivers, or socket wrenches. Its wide diameter adjustment range means that one size clamp can fit multiple sizes of hoses, reducing inventory costs for businesses.

Hose Protection and Extended Lifespan: High-quality American-style hose clamps have finely finished, rounded, and burr-free edges. This protects the hose surface from scratches during tightening and prevents hose breakage due to excessive localized force.

Wide Range of Applications

Due to its stable performance, American-style hose clamps are used in various high-standard industries:

- Automotive Industry: Used for connections in engine intake systems, cooling circulation lines, and fuel systems.

- Municipal Construction: Sealing and reinforcement of drainage pipes and HVAC systems.

- Chemical and Marine Industries: Providing reliable sealing in the transmission of highly corrosive liquids.

How to Choose High-Quality American-Type Hose Clamps?

When purchasing, it is recommended to pay attention to the following three points:

- Check the markings: Reputable manufacturers will clearly mark the material (e.g., W2, W4, W5) and specification range on the steel strip.

- Feel the edges: High-quality clamps have smooth edges without stamping cracks.

- Test the torque: Check if the screw rotates smoothly and whether there is stripping when tightened under high pressure.

As a core component of fluid connections, American-type hose clamps are not only hardware parts but also an important line of defense for ensuring production safety. Choosing clamps that meet standards and are made of high-quality materials can significantly reduce maintenance costs and avoid unexpected downtime due to leaks.